Pages

▼

Friday, June 30, 2017

Estes Apollo Little Joe II Build, Part 26, Tower Spot Fill

At the center of the "X" indent of the tower there is a round mold circle. There really isn't a way to use spot putty on it, it'd be very hard to sand smooth.

I squeezed out a drop of medium CA glue on some scrap cardboard. A blunt toothpick was dipped in the drop. This was set in the dent making a little pool. The drop stayed in the round dent.

It took two applications to fill the dent. No sanding was needed to smooth it out.

EDIT: After a shot of gloss white, I'll have to go back and do another application of CA glue filler. This might be more work than it's worth!

On the escape tower tube the ends were fuzzy after sanding down the first coat of white on the tower tube.

Some CA was applied with a Q-tip followed by light sanding. The CA was brushed on the inside and just over the top to the outside. Note the CA coat does not go deep into the tube. You don't want to seal the tube where plastic parts will be glued in later.

F-104 Starfighter Prototype Fix

On the first F-104 prototype I used some already cut dowels from the F-16 kit. Larger wing tanks will be used on the next build.

These larger tanks will change the C/G, I hope no nose weight is needed.

In the picture the larger new tank is set over the first one.

It's really not very difficult to shape the dowel ends. Each end takes about ten minutes of carving and sanding.

Trivia: Somewhere on line are the original plans for the the Estes Mars Snooper. The fin pods were made from just dowels, not nose cones and tubing.

Thursday, June 29, 2017

Ebay Auctions Ending

The Classic Estes (Semroc)

STARSHIP EXCALIBUR

Ebay auction is ending Thursday night!

This is a pretty one, I almost hate to see it go! (But I need room for other builds)

To see the auction - CLICK HERE

Also being auctioned:

The Estes PHOTON PROBE

This is the better of the two kits built on this blog.

It's an original kit from 1991-1993, not the Classic Series reissue.

To see this auction - CLICK HERE

Stop by, make a bid and support the blog!

The Flying Porta Pad Launcher

When I first saw the new Estes HEX-3 kit I didn't think of an odd-ball rocket.

HISTORY: This isn't the first card stock rocket kit. Centuri had their Two-Bits, Vulcan and X-24 kit back in the 1970s.

I saw the girders printed on the sides and was reminded of the original Porta Pad launcher.

HISTORY: The first Porta Pads were yellow then later orange. An all chrome version was in the Citation line starter set.

Here's my take on adapting the Porta Pad legs to the Hex-3 style design.

I didn't buy the Hex-3 kit, I enlarged the parts picture from the Estes website and drew up my own version. (Sorry, I can't email these drawings.)

Looking at it now, I should have made the center piece just a six sided cylinder, not a cone shape. The white "holes" in the legs could have been smaller. Oh well, the old timers will get it.

From the underside -

A heavy mat board support ring was cut. There is no need for an internal launch lug. The rod simply slides through the hole in the bottom ring beside the engine tube then through the split 20/50 ring at the top.

Wednesday, June 28, 2017

The Understanding Spouse

From Facebook and "The Grumpy Old Scale Modeler's Group" comes this video.

The scale model nerd tries to explain to his wife why he really needs this new kit. Be sure and watch to the end . . .

CLICK HERE

Estes Apollo Little Joe II Build, Part 25, A Slow Up!

I am getting to the painting!

The tower skirt and nozzles are painted black.

I did a simple mask over the glue areas.

Now the problem!!! It's Summer here and it is very humid.

Sprayed balsa and tubing tends to dry in a day or so.

Plastic is anther story. These spray painted parts stayed sticky for days! I can't slightly sand the base coats until it is dry to the touch.

This could slow down assembly and the blog posts.

Tuesday, June 27, 2017

LAUNCH, Schoolyard Soccer Field, June 26, 2017

With all the burn bans I haven't launched anything in two months!

I wanted to get in some test flights on new models to avoid an embarrassing stability moment at the upcoming Orlando R.O.C.K. launch.

To beat the wind I set out a little after 7:00 a.m. The soccer field grass was wet! In the end my shoes and pant legs were soaked and I had sweated through my clothes. I forget paper towels to dry off the models so I opened up a really old Estes wadding package and took out a few sheets. This wadding was aged to a fine brown color.

Maybe Estes shouldn't have posted a parts picture of the new HEX-3 on their website. This is one was pieced together last night, sprayed with clear right before walking to the field.

The Hex-3 looked like something from my past. It was re-drawn to look like the old yellow PORTA PAD LAUNCHER. It flew fine with a B6-2, Stable and slow to a height of 65'. Sorry, I can't send out PDFs on this one, Estes owns the concept and the new kit has just been released.

Here's another prototype that won't become a kit. (Quest wants too much for the surplus white decals from their old X-15 kit.)

The GOONY X-15 was stable with an A8-3, but way under powered. Altitude was only about 100 feet. Maybe I don't need that 1/2 oz. of clay in the nose cone.

Full Odd'l chute deploy and no damage.

Here's an old one, a stretched Quest Cobalt I painted orange and named it ORANGE. (How original.)

I really like how the Chinese A6-4 engines take a moment to build up thrust. When I use the burst feature in my camera I get seven pictures in a half second. Most launches are a blur but with the A6-4 engine you'll have three pictures of the rocket before it leaves the picture frame.

At ejection the chute stayed in the nose cone cavity. It bounced on landing but all fins stayed glued on.

I was nervous about this one, the new Odd'l F-104 prototype.

No reason to worry, boost was arrow straight with an Estes A8-3. Altitude was probably about 250 feet. Easy parachute eject and a soft landing with no damage.

Next test flight, a B6-4 at Saturday's R.O.C.K. launch!

So with all this under powered launch success I was feeling cocky. I pulled the Estes MOSQUITO out of the range box. (I usually keep a few smaller models ready for moments like this.)

Loaded with the powerful 1/4A3-3t engine, boost was quick to 200'. Against the white clouds I could follow the whole flight until ejection. Two black specks flew in different directions. Once I realized I was following a tumbling engine casing I looked back to the left but couldn't find the Mosquito. I turned to the ground and scanned the area.

featherweight or tumble recovery my foot! Good thing it was painted yellow. As always it was dug in, nose first.

Five launches, five recoveries with no damage.

I wanted to get in some test flights on new models to avoid an embarrassing stability moment at the upcoming Orlando R.O.C.K. launch.

To beat the wind I set out a little after 7:00 a.m. The soccer field grass was wet! In the end my shoes and pant legs were soaked and I had sweated through my clothes. I forget paper towels to dry off the models so I opened up a really old Estes wadding package and took out a few sheets. This wadding was aged to a fine brown color.

Maybe Estes shouldn't have posted a parts picture of the new HEX-3 on their website. This is one was pieced together last night, sprayed with clear right before walking to the field.

The Hex-3 looked like something from my past. It was re-drawn to look like the old yellow PORTA PAD LAUNCHER. It flew fine with a B6-2, Stable and slow to a height of 65'. Sorry, I can't send out PDFs on this one, Estes owns the concept and the new kit has just been released.

Here's another prototype that won't become a kit. (Quest wants too much for the surplus white decals from their old X-15 kit.)

The GOONY X-15 was stable with an A8-3, but way under powered. Altitude was only about 100 feet. Maybe I don't need that 1/2 oz. of clay in the nose cone.

Full Odd'l chute deploy and no damage.

Here's an old one, a stretched Quest Cobalt I painted orange and named it ORANGE. (How original.)

I really like how the Chinese A6-4 engines take a moment to build up thrust. When I use the burst feature in my camera I get seven pictures in a half second. Most launches are a blur but with the A6-4 engine you'll have three pictures of the rocket before it leaves the picture frame.

At ejection the chute stayed in the nose cone cavity. It bounced on landing but all fins stayed glued on.

I was nervous about this one, the new Odd'l F-104 prototype.

No reason to worry, boost was arrow straight with an Estes A8-3. Altitude was probably about 250 feet. Easy parachute eject and a soft landing with no damage.

Next test flight, a B6-4 at Saturday's R.O.C.K. launch!

So with all this under powered launch success I was feeling cocky. I pulled the Estes MOSQUITO out of the range box. (I usually keep a few smaller models ready for moments like this.)

Loaded with the powerful 1/4A3-3t engine, boost was quick to 200'. Against the white clouds I could follow the whole flight until ejection. Two black specks flew in different directions. Once I realized I was following a tumbling engine casing I looked back to the left but couldn't find the Mosquito. I turned to the ground and scanned the area.

featherweight or tumble recovery my foot! Good thing it was painted yellow. As always it was dug in, nose first.

Five launches, five recoveries with no damage.

Monday, June 26, 2017

F-104 Starfighter Prototype

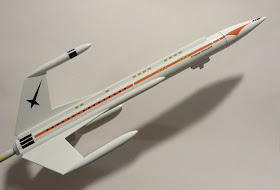

Here's the original Centuri F-104 Starfighter.

Note the rectangular cardstock intakes and wing tanks.

I just finished a prototype There were many changes from the Centuri kit.

The intakes are cut from a BT-20, a split nose cone is in the intake openings.

The tail shape was corrected, redrawn from profile photographs. The wing tanks are closer to the F-104 shape.

This is probably a Level 3 .5 build.

So what do you think - Should it be the next Odd'l kit? Many test flights first -

Estes Apollo Little Joe II Build, Part 24, Fin Gluing

I used 15 minute epoxy to glue the fin spar inside the fin.

NOTE: When you press the fin onto the spar, double check the leading edge of the fin to be sure it doesn't split open! One of my fins did split right down the seam. If the spar is too wide, wipe off the epoxy and sand it thinner. Work quickly, the epoxy in the fin is probably starting to set up!

If you feel like you are forcing the fin onto the spar, chances are it needs to be tapered thinner or shorter by sanding with 220 on a block.

Two fins were glued on opposite each other.

The front and rear were held in place with wide rubber bands while the epoxy set up.

The rear centering ring is still not glued in place!

That spray adhesive from the back of the wrap can show up everywhere if you aren't careful! After some handling, dirt showed where it still remained on the corrugated wrap.

TIP: When removing paint or glue, always start with the lightest solvent you have then move up to stronger solvents. Before using any Goo-Gone, I tried a Magic Eraser. I was concerned any strong solvent might effect the plastic wrap.

The damp eraser did remove the adhesive!

NOTE: When you press the fin onto the spar, double check the leading edge of the fin to be sure it doesn't split open! One of my fins did split right down the seam. If the spar is too wide, wipe off the epoxy and sand it thinner. Work quickly, the epoxy in the fin is probably starting to set up!

If you feel like you are forcing the fin onto the spar, chances are it needs to be tapered thinner or shorter by sanding with 220 on a block.

Two fins were glued on opposite each other.

The front and rear were held in place with wide rubber bands while the epoxy set up.

The rear centering ring is still not glued in place!

That spray adhesive from the back of the wrap can show up everywhere if you aren't careful! After some handling, dirt showed where it still remained on the corrugated wrap.

TIP: When removing paint or glue, always start with the lightest solvent you have then move up to stronger solvents. Before using any Goo-Gone, I tried a Magic Eraser. I was concerned any strong solvent might effect the plastic wrap.

The damp eraser did remove the adhesive!

Sunday, June 25, 2017

Estes Apollo Little Joe II Build, Part 23, Engine Mount Gluing

If you have added the fin spar reinforcements you should do some dry fitting before gluing in the engine mount.

The lower centering ring will sit slightly higher and butt up against the bottom flat of the fin spars.

A dry fit also lets you visually set the spars looking through the nozzle holes.

The fin spars were glued to the engine mount tube and to the inside of the body tube cut outs.

When you get the mount in place, draw some pencil alignment lines on the inside tube wall and lower ring. Reference the rear view in the instructions for nozzle placement in relationship to the tunnels M and N.

I'm not gluing the lower ring on so it can be flown without the nozzles in place.

Two wraps of masking tape kept the loose ring at the 1/2" mark.

Glue the engine mount in place with the lower ring on the engine mount tube. You can remove the tape and lower ring after the glue dries on the upper ring.

The instructions say to apply glue at 2 1/2" from the end of the tube. I drew a pencil line at 2 1/2".

The instructions say to apply glue at 2 1/2" from the end of the tube. I drew a pencil line at 2 1/2".

TIP: Gotcha - The upper ring ends up about 3/4" higher than the 2 1/2" glue ring. I would apply the glue higher at 3" in the tube.

A Q-tip taped to a dowel was used to smooth out the glue ring on both sides of the upper ring.

The lower centering ring will sit slightly higher and butt up against the bottom flat of the fin spars.

A dry fit also lets you visually set the spars looking through the nozzle holes.

The fin spars were glued to the engine mount tube and to the inside of the body tube cut outs.

When you get the mount in place, draw some pencil alignment lines on the inside tube wall and lower ring. Reference the rear view in the instructions for nozzle placement in relationship to the tunnels M and N.

I'm not gluing the lower ring on so it can be flown without the nozzles in place.

Two wraps of masking tape kept the loose ring at the 1/2" mark.

Glue the engine mount in place with the lower ring on the engine mount tube. You can remove the tape and lower ring after the glue dries on the upper ring.

The instructions say to apply glue at 2 1/2" from the end of the tube. I drew a pencil line at 2 1/2".

The instructions say to apply glue at 2 1/2" from the end of the tube. I drew a pencil line at 2 1/2".TIP: Gotcha - The upper ring ends up about 3/4" higher than the 2 1/2" glue ring. I would apply the glue higher at 3" in the tube.

A Q-tip taped to a dowel was used to smooth out the glue ring on both sides of the upper ring.

Saturday, June 24, 2017

Estes Apollo Little Joe II Build, Part 22, Tower Assembly

Mentioned earlier, the top left strut of the "X" aren't in the holes. The plastic was a bit warped.

It's easier to take care of this after the tower was glued up.

Push in the pin, brush on the glue and hold until dry.

Set the top into the escape rocket bottom and check the alignment.

Here's a dry fit.

This is an impressive assembly, almost worth the 47 years it took for me to get the kit!

Delay in the Estes Starship Nova Release?

Estes has had the Starship Nova shown on the Coming Soon page since March.

It seems this kit release has taken longer than normal.

A thread on YORF (CLICK HERE) might explain the delay. Go to Page 4.

Bob Sanford received an early release of the Estes Starship Nova kit -

Bernard Cawley posted:

"But if you look in Bob's second picture there you can see that the main body tube looks a little odd. Apparently there was some kind of miscommunication with the supplier and the BT-50 in the kits that are in the warehouse in Penrose don't have a glassine layer. So.....it may be a bit yet before the kits get distributed."

John Boren (of Estes) added:

"The first production run of this kit will in fact have tubes without glassine on them. The cost and time needed to get new tubes to China would stretch the release of this kit into at least first quarter of next year."

My thoughts:

It's not a big deal to buy a replacement BT-50 tube. The old kit instructions (CLICK HERE) say it is a BT-50K at 15" long.

If it were me, I'd buy a replacement BT-50H (heavier wall BT-50) before buying a kit with a no glassine layer tube. (See comment responses below - go with the BalsaMachining T50H-34 tube). BT-50 tubes are thin enough already and prone to buckles on a hard landing. Without that glassine layer, the tubes in the first run of the Starship Nova kits will be even thinner than normal. That thin plastic layer seals the tube and adds a lot of strength. Rough tubes can also suck up more paint.

I'm not complaining about a kit release taking some time. The Pigasus and F-16 kits took a year from initial drawings to the first kit sold. Stuff happens and you want it to be right!

I'm not complaining about a kit release taking some time. The Pigasus and F-16 kits took a year from initial drawings to the first kit sold. Stuff happens and you want it to be right!

Friday, June 23, 2017

Starship Excalibur Listed on EBAY

The Classic Estes (Semroc)

STARSHIP EXCALIBUR

is up for auction on Ebay!

This is a pretty one, I almost hate to see it go! (But I need room for other builds)

To see the auction - CLICK HERE

Also being auctioned:

The Estes PHOTON PROBE

This is the better of the two kits built on this blog.

It's an original kit from 1991-1993, not the Classic Series reissue.

To see this auction - CLICK HERE

Stop by, make a bid and support the blog!

Estes Apollo Little Joe II Build, Part 21, Tower Assembly

The visible mold seams were sanded lightly before assembly on the two largest outside pieces.

I only sanded down the seams that were on the outside. Nobody will see the slight mold seams on the interior.

A dry fit showed the upper strut wouldn't fit into the tower side. I didn't seat it, it'll be pushed in and glued after all four of the tower sides are glued on.

After the first two sides are dried the center ring is set.

One of the "X" strut centers didn't have a hole for the pine on the ring. I carefully spin drilled a recess into the X.

The ring fit well. Two small drops of glue were set into the X brace holes and the ring pressed in place.

Thursday, June 22, 2017

Model Profile - The Centuri F-104 Starfighter

The F-104 Starfighter was introduced in the 1977 Centuri catalog, the fourth model of the Fighter Fleet series. For variety, Centuri picked the West Germany motif

These jets had "fibre" fins, die-cut from a .050" thick card stock. While card stock made an easier assembly for a young modeler, older builders weren't too fond of the kits.

Many design compromises were made to the jets for vertical, stable flight.

This model isn't one of my builds. Lonnie Buchanon gave me some original Fighter Fleet rockets he found in Craig's list buy. An F-16 helped the design of my Odd'l Rockets kit.

The F-104 was 15" long and 1" in diameter. The tube was Centuri's heavier walled ST-10.

Here's some of the compromises -

For stability, the wings are set farther back. The intakes aren't round but long rectangle boxes formed from thinner card stock.

The bombs (or tanks depending on which model you were building) were the same used in all six of the Fighter Fleet series.

The missiles were also used on each model. They looked a little like a Sidewinder without the forward fins. The small nose and fin can were glued into a launch lug tube.

Notice the reinforcement pieces needed for the card stock wings and missile standoffs.

The model was 15" long, 5" of that was just the nose cone!

The cockpit decal is on but the clear canopy is missing. I don't know why the nose cone was never painted.

Why am I featuring this model? Stay tuned . . .

These jets had "fibre" fins, die-cut from a .050" thick card stock. While card stock made an easier assembly for a young modeler, older builders weren't too fond of the kits.

Many design compromises were made to the jets for vertical, stable flight.

This model isn't one of my builds. Lonnie Buchanon gave me some original Fighter Fleet rockets he found in Craig's list buy. An F-16 helped the design of my Odd'l Rockets kit.

The F-104 was 15" long and 1" in diameter. The tube was Centuri's heavier walled ST-10.

Here's some of the compromises -

For stability, the wings are set farther back. The intakes aren't round but long rectangle boxes formed from thinner card stock.

The bombs (or tanks depending on which model you were building) were the same used in all six of the Fighter Fleet series.

The missiles were also used on each model. They looked a little like a Sidewinder without the forward fins. The small nose and fin can were glued into a launch lug tube.

Notice the reinforcement pieces needed for the card stock wings and missile standoffs.

The model was 15" long, 5" of that was just the nose cone!

The cockpit decal is on but the clear canopy is missing. I don't know why the nose cone was never painted.

Why am I featuring this model? Stay tuned . . .

Estes Apollo Little Joe II Build, Part 20, RCS Housing and Nozzles

The RCS nozzles housings are small and slippery, no alignment pins!

Do your best to line up the sides and brush some glue on the outside joints.

On the left is before sanding the sides flat.

The inset shows the top seam is almost gone. The corners still need to be sanded.

On the sides stay away from the nozzle pins.

This is the RCS housing ready for the nozzles to be glued on.

There are 16 nozzles so set up an assembly line.

Glue on one nozzle, while that dries move on to the second RCS housing. By the time you've glued on the fourth nozzle on the last housing the glue should be dried on the first one.

Wednesday, June 21, 2017

Estes Apollo Little Joe II Build, Part 19, Escape Tower Nozzles

The tower and capsule plastic parts are made from the old Centuri kit molds. The newer Estes (lower body) plastic molds fit much better.

The (Centuri) escape tower nozzle halves don't have alignment pins. After glue was applied to the inside, glue was sparingly brushed on the outside. This liquid glue dries clean and doesn't distort the plastic. Go light.

The outside joint is a bit rough. The flash is scraped and the sides sanded smooth.

I had to sand the sides of the assemblies so they would slide together.

The inset shows the nozzle ends sanded flat and even.

Here's the two nozzle halves joined.

Don't worry about the top, it'll be covered by the tower cap.

The (Centuri) escape tower nozzle halves don't have alignment pins. After glue was applied to the inside, glue was sparingly brushed on the outside. This liquid glue dries clean and doesn't distort the plastic. Go light.

The outside joint is a bit rough. The flash is scraped and the sides sanded smooth.

I had to sand the sides of the assemblies so they would slide together.

The inset shows the nozzle ends sanded flat and even.

Here's the two nozzle halves joined.

Don't worry about the top, it'll be covered by the tower cap.