David Carllucy commented on a blog post:

David Carllucy commented on a blog post:"Have you seen these old kits?"

No I hadn't seen this one -

CLICK HERE to check it out.

This is a bagged Estes SCORPION, a Design Of The Month winner from July 1969.

I've heard that Estes did short runs of some contest winners. It was mentioned on TRF before. Maybe a market test?

To see the plans, CLICK HERE

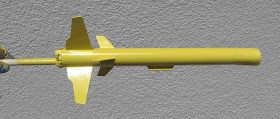

Here's what the Scorpion looked like.

Nope, it's not a boost glider. It has standard parachute recovery.

LOTS of wing area. On a windy day it might go horizontal.

It reminds me of the Skydart design.

And the second "kit" -

The Two-Stage DOUBLE TROUBLE.

CLICK HERE to see the eBAY listing.

To see the plans, CLICK HERE

I would guess these were released at the same time, both have the four color toppers and no face cards.

Am I going to bid? No.

Still, a real find for a collector.

UPDATE: From Bill Simon on YORF:

"Yes, Estes Ind. did "kit up" parts for some of the DOM models. It was Vern's idea to do so. I could have sworn that we offered them in the MRN, but after this many years, I'm fuzzy on the marketing details. I do know that we shipped of a bunch of them to the various NARAMs. Since I was back in Penrose minding the store while Vern, Bob Cannon and Norm Avery represented the company at the meets, I can only assume that we used them as free handouts."

Bill Simon