For all the "kids" who complain about how hard rockets are to build and paint -

Here's the detail painting directions from the original Estes Gemini Titan kit, #K-21 available from 1965-1973.

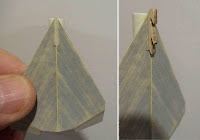

“Cut out the tracing patter. Cut out the two slots.

Cover the backside of the pattern with a soft lead pencil wherever lines or black areas of detail is to be traced.

Saturate a “Q-Tip or other swab with lighter fluid and wipe quickly over all the pencil marks. This “sets” the graphite and removes loose particles that may otherwise smudge the base finish.

Wrap the tracing pattern around the lower of the body tube with the slots positioned over the launching lugs.

Tape the side edges of the pattern together matching all lines. Use a straightedge where possible in tracing over all details. Remove the tracing pattern and be sure all details have been transferred to the body tube. Black enamel paint is recommended as it is less prone to leaving brush marks."

So basically - It's a home-made carbon paper transfer.

Rub soft pencil over the back of the printed sheet. The lighter fluid wipe is to remove excess pencil lead dust.

Wrap around the body tube with the black print side out and the pencil rub inside. Trace over the printed areas on the outside, (hopefully) transferring some of the rubbed pencil (on the underside) onto the body tube.

Remove the wrap. Then, hand paint all the squares and circles with black enamel paint. Hand paint?

I remember building this one in the mid 1970s. That lighter fluid wipe confused me. I didn't understand that the lighter fluid was to "set" the pencil rubs. I don't remember how I painted it. I only remember that only one of the two engines ignited. It turned over and nosed in.

The full instructions can be found at JimZs -

CLICK HERE