TOP TEN LIST FOR 2021

Here we go again! These are tough decisions to make.

Maybe it's the design, parts or how well it went together.

Sometimes it's simple, something I like about the model.

This list isn't from the worst to best, all Ten listed below are very good.

CLICK on the model name to go to the blog build or catalog page.

Sure it's self promotion - but it's always exciting to bring out a new kit!

A blog build is coming in the future . . .

A smaller 13mm two-stage rocket with a good build challenge. Perfect staged model for a small field.

8. ESTES DARC-1

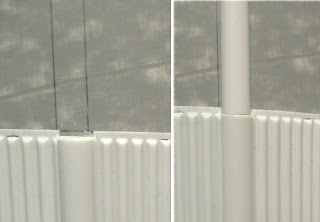

A tough to cut out nose section and difficult masks.

The finished model is impressive.

Even with 12 fins to fill this one is a favorite. If it wasn't sent back to Quest, it'd probably be a regular flyer.

6. ASP MMX HAWK

A very slick little MicroMaxx rocket! No balsa grain filling, the fins, nose cone and tunnel details are plastic.

The Countdown continues tomorrow, builds 5 to 1!