Well - The knife punch is too high for the upper bend of the engine hook. It has to be 1/4" down to allow for the engine block to fit flush with the top of the tube.

I made a new slit at the correct position. The wrong knife punch will be fine with the glued in engine block underneath it.

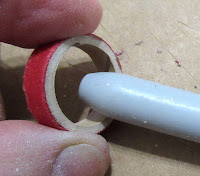

Press and smooth these down with a burnisher for an easier slide over the motor mount tube.

GOTCHA: There is a small mistake in the instructions.

The drawing shows the fins marking guide wrap still on the body tube with the fins glued on top! "Position finds on guide lines?"

The instructions don't mention not using the launch lug standoff. I used it.

Not a big deal, but the launch lug can be glued directly onto the body tube without the standoff.

On the left is a flight model with the balsa fins.

On the right, the show model with filled body tube seams and stronger basswood fins.

"Position finds on guide lines" looks like something written in a different language that had been (badly) translated to English.

ReplyDeletePerhaps one of the most infamous bad translations was in the videogame Zero Wing (which gave rise to the "All your base are belong to us" meme).

(shrug) At least using the standoff that isn't needed is better than not using a standoff (which may or may not have been mentioned in the instructions) when you really need one (perhaps due to something like a nosecone that was wider than the main body tube).

ReplyDeleteHi Naoto, As I found out, the Icarus used the same fins as a Quest Courier Egglofter. Because of the wider egg capsule nose cone on the Courier you'd need a launch lug standoff.

DeleteI kind of figured that it might be one of those cases of a part (e.g. die/laser cut fin sheet, nose/tail cone, decal sheet, detail parts, etc.) that is common between kits, and in such occasions, it's not unusual to end up with one or more unused parts.

Delete