Pages

▼

Sunday, March 31, 2019

New Estes Builds

Yesterday I received my first show builds from Estes.

There were four kits inside, two each of two upcoming kits.

I can't give out any other information now. When these are available for sale the builds will be featured on this blog.

Apogee SR-72 Darkbird Build Part 3, Wing Gluing

As I usually do, all the balsa parts were filled with CWF before gluing the model together.

This balsa is only 1/16" thick. When one side is brushed with CWF it did warp. But after the other side was treated the balsa straightened out again.

The side view shows how straight the three piece wing is after smooth sanding.

To try and save weight for a better glide, I didn't spray the parts with filler/primer. That was probably a mistake as you'll see later on.

TIP: After gluing on the inner wing, I used my aluminum angle to check the alignment of the long wing piece.

Note the wings were glued on 1/2" forward of the end of the BT-20 tube.

The side BT-5 tubes are glued onto the outside edge of the inside fins. These are also spaced 1/2" from the trailing edge of the inside wing.

My sanding block was used as a flat surface to check the alignment.

This balsa is only 1/16" thick. When one side is brushed with CWF it did warp. But after the other side was treated the balsa straightened out again.

The side view shows how straight the three piece wing is after smooth sanding.

To try and save weight for a better glide, I didn't spray the parts with filler/primer. That was probably a mistake as you'll see later on.

TIP: After gluing on the inner wing, I used my aluminum angle to check the alignment of the long wing piece.

Note the wings were glued on 1/2" forward of the end of the BT-20 tube.

The side BT-5 tubes are glued onto the outside edge of the inside fins. These are also spaced 1/2" from the trailing edge of the inside wing.

My sanding block was used as a flat surface to check the alignment.

Saturday, March 30, 2019

Apogee SR-72 Darkbird Build Part 2, Wings and Fins

The main fins are long, made up of three pieces.

I set them down on a straightedge. The upper picture shows the main wing before the edges were fitted.

The joint edges got hit with a sanding block until a good fit was achieved.

The outside part of the wing is made up of two pieces. Both were glued up on a straightedge.

The instructions said to use CA glue for most of the rocket construction. I used yellow wood glue.

The instructions don't mention it, but I did round the leading edges of the wings after everything was glued together.

For the first time in a while - The tube marking guides actually fit the tubes. Everything wrapped and lined up. Thanks Apogee!

Why can't all the vendors get this right?

I set them down on a straightedge. The upper picture shows the main wing before the edges were fitted.

The joint edges got hit with a sanding block until a good fit was achieved.

The outside part of the wing is made up of two pieces. Both were glued up on a straightedge.

The instructions said to use CA glue for most of the rocket construction. I used yellow wood glue.

The instructions don't mention it, but I did round the leading edges of the wings after everything was glued together.

For the first time in a while - The tube marking guides actually fit the tubes. Everything wrapped and lined up. Thanks Apogee!

Why can't all the vendors get this right?

Friday, March 29, 2019

Apogee SR-72 Darkbird Build Part 1, Parts

I bought this rocket a few years back, directly from Apogee.

The SR-72 Darkbird is 14" long, the main airframe is a BT-20.

This pop-pod boost glider operates like the Estes Sky Dart and the original Citation Bomarc. The long engine pod is ejected and returns via streamer. When the pod ejects, the elevons lift and the main body goes into a glide. The elevons are held down during boost. The elevon "up tension" is activated by small orthodontic rubber bands.

I asked Tim VanMilligan why it was called the SR-72. He said it was the next generation of the SR-71, a fantasy stealth bomber.

There are four 5/20 centering rings. The two identical die-cut balsa sheets are 1/16" thick.

To the right, the parts of interest:

I only found one orthodontic rubber band in the bag, I have others.

EDIT: In a comment, Eero Fluge pointed out, the second rubber band was around the streamer! I looked right past it and probably threw it away.

Two BT-5 sized vacu-form ram-jet nose cones.

The red Mylar pop-pod streamer.

At the bottom is the almost transparent elevon hinge material

In the center, the cast elevon hold down ring.

The SR-72 Darkbird is 14" long, the main airframe is a BT-20.

This pop-pod boost glider operates like the Estes Sky Dart and the original Citation Bomarc. The long engine pod is ejected and returns via streamer. When the pod ejects, the elevons lift and the main body goes into a glide. The elevons are held down during boost. The elevon "up tension" is activated by small orthodontic rubber bands.

I asked Tim VanMilligan why it was called the SR-72. He said it was the next generation of the SR-71, a fantasy stealth bomber.

There are four 5/20 centering rings. The two identical die-cut balsa sheets are 1/16" thick.

To the right, the parts of interest:

I only found one orthodontic rubber band in the bag, I have others.

EDIT: In a comment, Eero Fluge pointed out, the second rubber band was around the streamer! I looked right past it and probably threw it away.

Two BT-5 sized vacu-form ram-jet nose cones.

The red Mylar pop-pod streamer.

At the bottom is the almost transparent elevon hinge material

In the center, the cast elevon hold down ring.

Thursday, March 28, 2019

Custom SLV Build #10044, Finished

The picture at the left shows the wrap edge matches.

This is a detailed model at a good price. There were a few glitches along the way, the miss-matched lower shroud could be a problem for a younger builder. This is listed as a Skill Level 4 kit.

While I'm not a big fan of stickers, the trim looks great. Two main colors in white and black with the third smaller orange trim.

Wednesday, March 27, 2019

Custom SLV Build #10044, Part 12, Sticker Trim - Clear Peel & Stick

There is still one more large white paper shroud sticker.

There is no reference for the starting position. Set down lightly, check the end alignment, lift and try again until everything lines up.

Again, notice the seams all start and finish down the launch lug line.

There are numbers that go between every two facing fins. Using a knife blade tip for positioning is easier than using your fingers.

The face card shows small square stickers under the numbers. These probably should have been printed on the sheet directly below the numbers so both could be set down at the same time. I left them off.

The UNITED STATES clear sticker goes down the upper tube, centered between the other decor bands.

Notice the center pencil marks. Mark the tube area center and mark the sticker. This saves you some time when getting the sticker in the right position.

GOTCHA: While the rocket design looks good, there isn't much room for the parachute in the upper short BT-50 tube. I'll probably have to fold the 12" chute in half and work it into the lower BT-20 tube. It won't fit into the BT-50 section when you add wadding and the length of the nose cone shoulder.

Monday, March 25, 2019

Custom SLV Build #10044, Part 11, Sticker Trim - White Peel & Stick

The kit includes two small sheets of peel and stick decor, one white paper and one clear plastic. I applied the white roll patterns first.

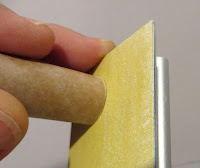

Always do a dry fit before peeling off the backing paper.

Here I found out the wrap didn't meet up, so position the ends (start and finish) in the back down the launch lug line.

There is a small gap but it won't be seen with the launch rod behind the model.

TIP: Face all the gaps and seams in line - on the back side of the rocket.

There are no cutting guidelines so I cut them close and hoped for the best.

You are able to position and lift the stickers a few times to get the positioning right. It took a few tries to get the ends to match up.

I did another masking tape line to help with the visual gap spacing at the top. The correct fit of the wrap is also dependent on where you start the wrap, higher or lower on the shroud.

Always do a dry fit before peeling off the backing paper.

Here I found out the wrap didn't meet up, so position the ends (start and finish) in the back down the launch lug line.

There is a small gap but it won't be seen with the launch rod behind the model.

TIP: Face all the gaps and seams in line - on the back side of the rocket.

There are no cutting guidelines so I cut them close and hoped for the best.

You are able to position and lift the stickers a few times to get the positioning right. It took a few tries to get the ends to match up.

I did another masking tape line to help with the visual gap spacing at the top. The correct fit of the wrap is also dependent on where you start the wrap, higher or lower on the shroud.

Custom SLV Build #10044, Part 10, Masking Fins & Dowel Trim

All six fins are masked and painted gloss black.

Even though the fin leading edges were left square, I still do a diagonal mask over the top corner tips. On the left there is one diagonal corner masked off. I've yet to add the second piece on the lower side. This just leaves off the corner ticks.

I thought the dowels would be too hard to paint with a brush after they were glued on, centered at the two BT-20 body tube joint. I painted them black earlier.

I only used six of the eight dowels.

A strip of masking tape was rolled on for low end positioning. A pencil line was drawn and the paint carefully scraped for best glue adhesion.

The dowels were glued on and in line with the six fins.

Just like the stick on decals cover up the shrouds, the dowels visually camouflage the body tube seam joint.

Sunday, March 24, 2019

Custom SLV Build #10044, Part 9, White Undercoat & Sanding

TIP: I'll usually paint a model with the nose cone slightly pulled out, maybe 1/16". This gets a bit of paint inside the shoulder. When the model is on the launcher sometimes the nose cone isn't fully seated in the tube. If you take a picture before the flight you won't see the unpainted shoulder. In this kit, the nose cone is black plastic.

Here's the model after the first white undercoat has dried. I've done some light sanding on the surfaces, smoothing out any glue blobs. Look close at the launch lug fillet. I did have to sand down through the paint to smooth it out.

The body tubes joint wasn't smooth. After sanding I could see this would require another white coat, sanding again and then a final coat of white.

The shroud joints also needed more sanding. The paint does act like a final filler after the sanded CWF and filler/primer coats.

Here's both of the shroud adapters after the last heavier coats. The final finish coat should be applied slower and thicker, but not heavy enough to cause runs.

Interesting thing about this Custom kit, the sticker decor does help cover up any flaws in the shrouds.

There is a little distortion in the pictures, the shrouds are actually on straight.

Saturday, March 23, 2019

Custom SLV Build #10044, Part 8, Fin & Launch Lug Gluing

The instructions say to glue on the dowels centered over the tube joint. They are painted black afterwards with a small brush.

The dowels would be hard to paint black after gluing in place.

I set them down on a strip of masking tape and hit them with a coat of filler/primer. The backs won't get any paint so they can be glued to the tube later.

After sanding the dowels were stuck down again and sprayed gloss black.

The six small fins were glued onto the lower BT-60, even with the end of the tube.

After three were glued on, the remaining three fins were glued between those.

I probably should have scraped off the launch lug locations before the fins were glued on. I was able to scrape the filler/primer for a glue line but had to be careful between the fins.

The builder has to assemble the 12" parachute.

The tape disks and shroud lines are adhered the old school way, a simple loop of the shroud line and a tape disk.

I wanted a stronger attachment. The disk was pressed in place, a hole punched and the shroud line tied on.

The dowels would be hard to paint black after gluing in place.

I set them down on a strip of masking tape and hit them with a coat of filler/primer. The backs won't get any paint so they can be glued to the tube later.

After sanding the dowels were stuck down again and sprayed gloss black.

The six small fins were glued onto the lower BT-60, even with the end of the tube.

After three were glued on, the remaining three fins were glued between those.

I probably should have scraped off the launch lug locations before the fins were glued on. I was able to scrape the filler/primer for a glue line but had to be careful between the fins.

The builder has to assemble the 12" parachute.

The tape disks and shroud lines are adhered the old school way, a simple loop of the shroud line and a tape disk.

I wanted a stronger attachment. The disk was pressed in place, a hole punched and the shroud line tied on.

Custom SLV Build #10044, Part 7, Dowel Trim

Two dowels are provided for trim. Short lengths go over the joint between the two body tubes.

Sand the dowels smooth with 400 grit before cutting them to length.

Both dowels are cut to 1 1/2" lengths, four lengths from each 6" dowel.

GOTCHA: I checked the length and found the dowels were just short of the 6" length needed. I wanted all eight dowels to be the same length so I cut them all a little short at 1 7/16" long.

TIP: It's easy to roll a knife blade over a dowel to cut it. It's also very easy for that cut line to travel.

Go slow - Roll forward a half turn around the dowel then roll back to your starting pint. Roll back a half turn and joint the cuts.

Make sure the blade is perpendicular to the dowel and take it slow until the cut line is established.

Before filler/primer is sprayed, set all the dowels on a straight edge to be sure they are all the same length.

Friday, March 22, 2019

Custom SLV Build #10044, Part 6, Upper Shroud & Tube Gluing

On the left I'm rolling off the inside burrs so the ring will slide over the BT-20 a little easier.

On the right are both 20/50 rings stacked and glued even with the top of the second upper BT-20 tube.

The instructions say to apply a ring of glue 3/4" from the bottom of the lower ring. A dry fit showed the glue line should go a little below that. Dry fit the shroud and trace the low edge with a pencil to find the line.

Note there is very little glue where the shroud edges will make contact.

TIP: Before gluing any two tubes together with a coupler, sand the ends flat and do a dry fit. You might be surprised how many kit tubes are not cleanly cut.

After the tubes were joined the assembly got a shot of filler primer and fine sanding. There were some high areas especially around the seam joints.

Thursday, March 21, 2019

Custom SLV Build #10044, Part 5, Lower Shroud Assembly

Looking ahead in the instructions -

The two remaining 20/60 rings are glued together. These will support the base of the card stock shroud.

TIP: Plan ahead - Be sure you have a good fit over the BT-20 tube before gluing the rings inside the shroud base. You wouldn't want to have any problems trying to force a tight fitting ring over the BT-20 with the flexible shroud on top.

The ring is lightly pressed in place with no glue. Try to get it evenly spaced around the edge.

TIP: Apply a LIGHT glue fillet around the edge, applied with a Q-tip. You won't need much glue, too much glue could soften and deform the shroud edge.

TIP: Don't just blindly glue the card stock adapter in place. Slide it down and check the fit. Rotate the shroud around the tubes until you find the best fit at the joint. Mark the best fit with pencil on both parts (see left). At the top, draw a pencil line around the top of the shroud. This is your glue line for the top joint.

Apply a small bead of glue on the top of the BT-60 and a hair below the pencil line.

Apply a small bead of glue on the top of the BT-60 and a hair below the pencil line.

DON'T USE MUCH GLUE! You wont need it.

Slide the shroud down the tube from the top, turn the shroud and line up the pencil "best fit" lines.

TIP: While the glue is still wet, "mold" the wet soft edges with a Sharpie barrel or smooth, clean dowel.

The two remaining 20/60 rings are glued together. These will support the base of the card stock shroud.

TIP: Plan ahead - Be sure you have a good fit over the BT-20 tube before gluing the rings inside the shroud base. You wouldn't want to have any problems trying to force a tight fitting ring over the BT-20 with the flexible shroud on top.

The ring is lightly pressed in place with no glue. Try to get it evenly spaced around the edge.

TIP: Apply a LIGHT glue fillet around the edge, applied with a Q-tip. You won't need much glue, too much glue could soften and deform the shroud edge.

TIP: Don't just blindly glue the card stock adapter in place. Slide it down and check the fit. Rotate the shroud around the tubes until you find the best fit at the joint. Mark the best fit with pencil on both parts (see left). At the top, draw a pencil line around the top of the shroud. This is your glue line for the top joint.

Apply a small bead of glue on the top of the BT-60 and a hair below the pencil line.

Apply a small bead of glue on the top of the BT-60 and a hair below the pencil line.DON'T USE MUCH GLUE! You wont need it.

Slide the shroud down the tube from the top, turn the shroud and line up the pencil "best fit" lines.

TIP: While the glue is still wet, "mold" the wet soft edges with a Sharpie barrel or smooth, clean dowel.

Wednesday, March 20, 2019

Custom SLV Build #10044, Part 4, Shrouds - Oops!

After trying to form one of the larger lower shrouds I found a problem.

GOTCHA: Look at the ruler next to the shroud sides. One side is 1/32" wider than the other! You couldn't get a good fit on the BT-60 side of the adapter.

Here's what I mean -

The wide end of the shroud is uneven.

TIP: Always scan and print up extra shrouds. You never know when you might need extras. I wish every kit included more than one!

Here's my quick-fix -

I cut the arc a little wider on the outside. It's worth a try!

Tuesday, March 19, 2019

Custom SLV Build #10044, Part 3, Engine Mount Placement

Here's how the instructions say to lay in glue beads in the 3" BT-60 tube. When assembled, the top and bottom rings are to be flush with the ends of the body tube. The instructions imply a lot of glue, on all parts.

I cut the replacement BT-60 tube at 3 1/16" so I could have an overhang and a fillet ring at the bottom.

The top rings will be flush with the tube edge.

A ring of glue was applied around the inside top after the bottom rings were slid in - otherwise most of the glue would be slid around throughout the inside of the tube.

On the left is the top ring, flush with the edge of the BT-60 tube.

On the right is the back end. You can see the slight body tube lip extending beyond the ring face. This allows me to apply a glue fillet in that lip edge.