For those building Goblin families, this is about as small as you can go.

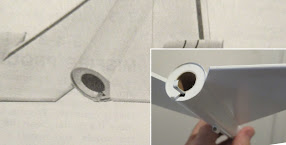

1/8" diameter launch lugs look big on these tiny models.

You could use MicroMaxx motors but I prefer a 1/2A-2t or 1/2 A3-4t motors. If made for MicroMaxx flights, you probably wouldn't need the clay nose weight.

Here's the mini model to the right of a standard BT-55 based Goblin.

Home print skins aren't as bright as a regular spray painted model, but the Goblin vibe is still there!

These little guys are great for first flight of the day or decorating the Christmas tree alongside the Estes plastic ornaments.