The original kit had two engine blocks,

one for the engine stop, the second to tie a rubber shock cord. No parachute or streamer, just nose-blow recovery.

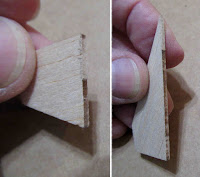

Enlarge the picture on the left.

I can't imagine trying to slide in that upper block ring into a ring of glue with a binding rubber shock cord tied around it.

I'll be installing a single lower engine block with a tied on Kevlar line.

The inside 1/8" (or so) of the tube got a wipe of CA glue. This was followed by sanding just the edge with 400 grit on a block.

The engine block got a notch for a better fit of the Kevlar line tie.

I used a spent "T" motor to position the engine block and Kevlar line.

Occasionally your find a raised cut-off burr on the end of the casing. Roll that off with some 400 grit.

This makes for an easier slide into the engine mount tube.

TIP: When installing an engine block, have ALL your parts close at hand. You don't want to be looking for the engine block as the glue in the tube is starting to set.

The glue applying dowel is marked with a pencil ring about 1 1/2" from the top.

A ring of glue is set around the top of the dowel.

Set the dowel in the tube up to the pencil line trying not to touch the inside walls of the tube.

Roll the dowel and transfer a line of glue around the inside of the tube.

Quickly set in the engine block and push into position, with 1/4" of the engine casing extended out the bottom of the tube. Remove the casing.