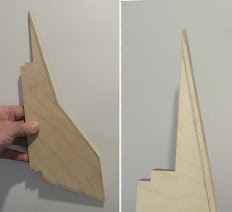

Here's the scan of the intakes from the Jim Z's website:

I appreciate the patterns, but sometimes the scans are a bit rough.

Good thing the ruler is on the scan!

I dropped the art into Corel Draw and drew a 1" square box.

The art was sized so the 1" square box matched the 1" measure on the ruler.

Drop down a horizontal alignment line. Double click the intake scan and you can rotate it.

Start drawing the outside cut lines and the inside fold lines.

Start drawing the outside cut lines and the inside fold lines.

To be sure the long top and bottom trapezoid shapes are the same size, I drew a box that aligned with the top half.

Copy and slide down the copied box to check the lower half height.

The folds got a dashed line.

Great thing about computer graphics,

Copy the original, paste and drop down an exact copy.