Here's all three of the Red Max models.

On the left is the standard BT-60 based original.

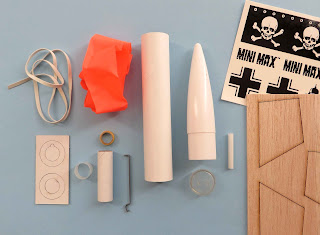

Next to it is the BT-50 based Mini Max.

Laying on its side is a BT-5 carded Red Max. It was drawn up by Bob Harrington.

And the Hello Kitty Pink Max duo.

Decals on the BT-60 standard were done by Excelsior.

Decals on the pink Mini Max were reduced pictures of the Excelsior decals.

I'm not making the Pink Mini Max decals available.

Don't ask - I don't want to hear from the Hello Kitty legal team.

They won't sue me for making a "one-off" personal use model.

Notice how small the iron cross fin decal is on the larger Pink Max model. The iron cross on the Mini Max is the correct larger size. That was fixed in a previous post.