TIP: When gluing up a pre-finished model like this, use white glue, not yellow glue. Some glue might end up on an outside surface, visible on the finished model. White glue dries clear, yellow glue dries yellow.

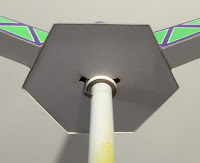

Here's the bottom outside tip of the fins.

Be sure the bottoms of the tab flaps are even as shown on the right, not as shown on the left.

I found long tweezers really help to hold the tabs together until the glue starts to set.

That launch lug hole in the center body skin is difficult to cut with a knife.

Use your leather punch to cut out the hole. Cut the straight sides of the lug slot with a knife.

TIP: The instructions usually have you set glue on the extended short glue tab. Sometimes glue squeezes outside the body.

I like to set glue on the inside edge, opposite the tab side. on the center right, I've marked the glue area with pencil.

Give this a try, you might feel it gives you more control. After you apply the glue to the opposite side, you can smooth it out with a fingertip right up to the edge of the shroud.

Press the dry tab into the glue on the other side.

I've set a dowel inside the body shroud to give me a hard surface for burnishing.

Rub a dowel down the gluing area tab while pressing against the dowel on the inside.

Many builders use too much glue when adhering card stock. Apply glue, smooth out and remove excess with a finger.