I'm a little embarrassed -I built a few Antars for Estes and didn't notice the silver line running down the leading edge of the wings. I tend to follow the instructions and plan ahead, but didn't see the silver trim.

The Antar is a difficult model to mask and paint. I wasn't excited about another thin mask down the wing edge so I decided to try something new.

Sprayed decal trim has it's place and has worked in the past. But, this trim strip rolls over the round leading edge of the wing. It'll have to be wide enough to hold on when set onto the top and bottom.

This is not an easy technique and might be avoided if you aren't comfortable using water slide decals.

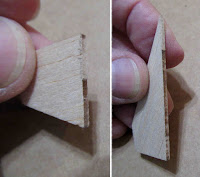

I sprayed silver paint on a scrap piece of white decal paper. White decal paper will show off the silver better than a clear decal sheet.

The spray paint seals the surface, no additional clear coat is needed. After the paint dries, you can go right to cutting and a water soak for transferring.

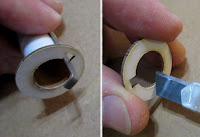

The strip is about 1/4" wide. The front end is rounded to roll around the leading edge. I was surprised how the rounded edge of the decal disappeared into the fin tip fillet.

The decal strip was cut a little long and will overhang the the end.

After the decal is fully dry, the overhang was trimmed off with a

new single edge razor blade. Try using a back and forth sawing motion.

The decal strip held well but might curl and lift over time.

I don't like clear coats but used a little Pledge clear acrylic on this one.

It won't take much. Dip the brush and wipe off the excess.

Run the brush over the edge of the decal, only covering about an inch at a time.

Immediately wipe off the shiny excess.

There will be some of the Pledge that will run ender the decal edge helping it adhere to the surface.

That silver trim line adds a lot to the finished build.