Wrap around the tube and mark the overlap. Trim a little oversize.

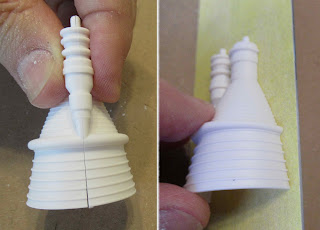

Then sand and check the fit.

Repeat until both ends match up with (hopefully) an equal spacing between the ribs and very little seam to fill.

Notice on the right side - pencil marks to reference the 1/16" wide edge border cut.

Before spraying the backs with adhesive -

Double check to be sure you are spraying the back side.

I use a small roll of tape to hold the wrap down on scrap cardboard for adhesive spraying.

Spray directly over the back, not from the sides. You want the adhesive just on the back. It would be difficult to remove adhesive from between the corrugation ribs.

I used the 3M Super #77 permanent spray.

You will be lining up the left edge of the wraps down the vertical pencil line.

GOTCHA: The Upper 2nd Stage Wrap end does not start on the pencil line!

Check the single conduit position on the Second Stage Wrap and line up the conduit top in the upper wrap to find the correct start position.

Be sure to double check the alignment of the conduits. Sight from the rear.

If they are not in line, the conduits will end up looking crooked on the finished model.

A few points didn't want to stay down on the body tube.

Some CA glue was slipped in on a knife blade.

A smooth pointed dowel held down the raised areas as the glue set up.