I used Titebond M&T glue for fillets on the lower 2/3rds of the intake joint. There is no way to get a good glue fillet under the inside top of the intake.

The Titebond M&T Glue skins over before you can wipe it off. I decided to use white glue for the fillets under the intake front.

You can't apply it right out of the bottle, the nozzle won't fit.

I used a small drop on Q-tips to transfer the glue then immediately wiped off the excess.

Glue was applied to the rounded top of the intake first, then the sides were done.

Use a Q-tip once, then throw it away.

After the upper white glue fillets dried -

I lightly dragged the tip of my knife blade over the upper intake joint and could feel bubbles in the dried white glue.

I went back and did the upper fillets using Titebond M&TG.

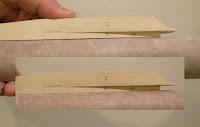

The fin tabs were just a little long on all four fins.

On the left is the before, the inset picture shows the fit fin after sanding down the tab.

Saturday, October 31, 2015

Super Glue Questions Part 2

Thin CA glue flows fast and can clog up the nozzle that comes on the bottle.

You might try to find some Teflon tubing to slip into the pointed nozzle end. I found some at Hobbylinc - CLICK HERE

You will have to cut a little more off the pointed nozzle to get the Teflon tube in. Cut off a sliver and see if the Teflon tube fits. Keep slicing off small bits until the tube friction fits into the nozzle.

Cut off 1/2" of Teflon tube and use tweezers to push it into the new cut hole.

When the tip gets logged, use a wire (I use a "B" string off a guitar) to clear it.

When the tube gets bad, pull it out and put a new length in.

After you are done using the glue you should clear the tube. Hold a paper towel over the nozzle tip and squeeze the bottle. This blows out the glue left in the tube and prevents dried clogs.

When using the Teflon tube, you don't put the cap over the nozzle.

Put it in the fridge with the tube in place and it should be fine.

You might try to find some Teflon tubing to slip into the pointed nozzle end. I found some at Hobbylinc - CLICK HERE

You will have to cut a little more off the pointed nozzle to get the Teflon tube in. Cut off a sliver and see if the Teflon tube fits. Keep slicing off small bits until the tube friction fits into the nozzle.

Cut off 1/2" of Teflon tube and use tweezers to push it into the new cut hole.

When the tip gets logged, use a wire (I use a "B" string off a guitar) to clear it.

When the tube gets bad, pull it out and put a new length in.

After you are done using the glue you should clear the tube. Hold a paper towel over the nozzle tip and squeeze the bottle. This blows out the glue left in the tube and prevents dried clogs.

When using the Teflon tube, you don't put the cap over the nozzle.

Put it in the fridge with the tube in place and it should be fine.

Friday, October 30, 2015

QCC Explorer on EBAY

The finished Estes QCC Explorer is up for Auction on EBAY.

To see the auction, CLICK HERE

This build has some custom improvements - a payload section, replaceable Kevlar, 1/4" wide, long shock cord and some metallic paint upgrades.

Support the Blog, make a bid!

Estes QCC Explorer Build Part 17, Gluing On The Intakes

I made a four fin marking guide and used the fin lines to line up the left side of the intakes.

The entire intake sides were traced with a pencil.

Inside the pencil lines, the primer was scraped off down to the tube.

The first two intakes were glued on opposite sides and spaced visually from the rear.

A piece of paper was marked and used to guarantee the space between the intakes was consistent.

The flat side of a sanding block was set against the tube end to be sure the rear of the intakes were even with the bottom of the body tube.

Thursday, October 29, 2015

Estes QCC Explorer Build Part 16, Ends and Edges Prep

Here's a dry fit of an intake and fin. The fin won't be glued in until after the intake is glued onto the body tube.

This is an impressive assembly unlike anything I've seen before.

I did a pull on a shroud line and it broke pretty easily.

I got out the 100% cotton embroidery thread and replaced all the lines.

When the intakes are glued on it'll be very hard to get the white paint underneath.

I sprayed some white in a small cup and brushed it on the inside surfaces.

This is the before and after showing the painted underside of the intakes.

I also painted the inside walls of the open top intake where I knew the spray paint wouldn't reach.

This is an impressive assembly unlike anything I've seen before.

I did a pull on a shroud line and it broke pretty easily.

I got out the 100% cotton embroidery thread and replaced all the lines.

When the intakes are glued on it'll be very hard to get the white paint underneath.

I sprayed some white in a small cup and brushed it on the inside surfaces.

This is the before and after showing the painted underside of the intakes.

I also painted the inside walls of the open top intake where I knew the spray paint wouldn't reach.

A TRF Forum Response from John Boren of Estes

Jumpjet

Senior Member

Senior Member

A couple of personal thoughts about STUFF.

The one thing I've come to realize in reading forum posts is that everyone has their own opinions. I may disagree 100% with that opinion, which of course is simply my own opinion. To say the Estes 29mm E16 & F15 motors aren't impressive to watch fly in a Pro Series size model is in my opinion a false statement. There are MANY people out there that love to see a large model take off slowly, arc over and then to actually be able to see the chute eject and open up. There are others that like to use V-Max type motors where you see NOTHING of the flight since the rocket is there one second, gone the next and then the next time you see it is when the model is floating down. I prefer the slower type of flight. I also prefer models that don't go much higher then what I can see, while others like to fly just under the fields maximum flight waiver if you fly at a club. Again everyone has their opinions. I've learned over my time here as the sole designer of Estes rocket kits to ignore people who have very STRONG opinions to put it mildly. Product is produced for the masses, meaning it isn't produced for the few thousand people that view the forums and the much lesser of which actually post a message. If product was only produced for the forum type modelers, Estes would be out of business since there simply isn't enough of you to keep us in business. With that said, do I listen to what people would like Estes to bring back or make new, sure; I've been designing, building and flying model rockets for some 45 years now and most likely think rocket XYZ was super cool looking when I was growing up and think it would be cool to others as well if it was brought back as a kit.

As for, is the entire line of Pro Series builder kits going away, I can't personally answer that, since I'm not in charge of what is or isn't going to be discontinued and even then the person(s) in charge of this can change their mind. I would say however that if you like what you see, buy it now even if your only intention is to us the kits for parts.

In a perfect world everyone ones opinion would be ignored and they would simply listen to what I say. (Jedi Mind Trick) You don't need to eat and pay your mortgage, you need to buy more Estes Rocket Stuff!

John Boren

There are plenty of opinions on the forums. With some, it's there way or no way at all.

I agree John, I like to watch the entire flight including ejection, rather than hope to see it coming down on the horizon.

I've been to certain club launches where some turn up their nose to the BP, LPR guys.

I respect the MPR and HPR launches. I still find LPR to be challenging. Anything done well is a challenge.

Fast launches? Launches are usually too fast anyway. I prefer the flights I can follow without whiplash.

Even on a small scale, People have asked me: "Why did you discontinue that Odd'l kit?"

Simple answer: "Well, it didn't sell".

Wednesday, October 28, 2015

New Estes Products

It's a Pro Series II model using the Argent fins.

To see the specs, CLICK HERE

The 2015 Christmas ornaments are here:

CLICK HERE

Estes QCC Explorer Build Part 15, DIY Payload Section Coupler

Two holes are punched in the disks. The shock cord will be tied through these.

Two holes are punched in the disks. The shock cord will be tied through these.Now the disk can be glued in over the reinforcement ring.

The reinforcement ring prevents the disks from being pulled down or out.

The red coupler is 3" long. Mark the center at 1 1/2". The lower half got a coat of medium CA.

Leave the upper half of the coupler as is, no CA coat. The upper 1 1/2" will glue into the 8" payload section tube.

After the CA dries, sand smooth with 400 grit.

Round the ends of the coupler edge for easier insertion in both tubes.

All open tube ends got a coat of medium CA and smooth sanding.

Don't use CA on a tube end that will have something glued into it.

Tuesday, October 27, 2015

Estes QCC Explorer Build Part 14, DIY Payload Section Coupler

The upper 8" of the rocket are a second, coupled tube. This makes for an easier color separation, don't glue the two tube sections together until after painting.

Anytime I see a model with a second body tube section I look for a way to make it into a payload section.

The red coupler will glue into the 8" section of tubing. The lower half of the coupler will slide into the longer, lower body tube.

Trace around a BT-60 tube onto some heavy cardstock.

Draw two circles.

Even though the card stock is thick I can still make a rough cut with scissors. Cut just inside the pencil lines, the circles will have to slide into the BT-60.

Glue the two disks together and let dry in a heavy book.

For a reinforcement ring I cut a 3/4' length of scrap BT-60 coupler.

Make a straight split cut through it and slip into the red coupler from the kit.

Mark the overlap and cut off the strip.

The reinforcement ring is glued flush inside the end of the red coupler.

The inset picture shows a dry fit (no glue yet) of the laminated disks after sanding the sides until it fits.

Anytime I see a model with a second body tube section I look for a way to make it into a payload section.

The red coupler will glue into the 8" section of tubing. The lower half of the coupler will slide into the longer, lower body tube.

Trace around a BT-60 tube onto some heavy cardstock.

Draw two circles.

Even though the card stock is thick I can still make a rough cut with scissors. Cut just inside the pencil lines, the circles will have to slide into the BT-60.

Glue the two disks together and let dry in a heavy book.

For a reinforcement ring I cut a 3/4' length of scrap BT-60 coupler.

Make a straight split cut through it and slip into the red coupler from the kit.

Mark the overlap and cut off the strip.

The reinforcement ring is glued flush inside the end of the red coupler.

The inset picture shows a dry fit (no glue yet) of the laminated disks after sanding the sides until it fits.

Super Glue Questions Part 1

On the Rocketry Center Forum, Kirk G asked about Super Glues:

His questions are in italics.

First up -

Super Glues get hard and brittle over time.

A older rocket constructed with Super Glue will have parts pop off during boost and on landing.

Don't use Super Glues to glue on fins, launch lugs or engine mounts.

In rocket construction it's only good for strengthening up a lip on a body tube, hardening a card stock shroud or lightly tacking some things in place.

Never use Super Glue on knots or shroud line knots. It runs up the line making it stiff and brittle.

IS there a shelf life to CA?

To extend it's life, keep it cold in the refrigerator.

Don't store it in the door, it might fall over and leak.

Is it known for leaking out of a plastic squeeze bottle?

Only when it's turned on its side! Don't let in fall over.

How often do you buy new CA, and in what quantity?

I buy small bottles as needed.

"Is there any way to revive an "old" or "Turned" bottle?"

Not that I know of.

What is best for rocketry? Thin? Thick? or other 'brand'?

I have thin and medium. I buy the thin in a small bottle at a hobby store.

Unless you use a LOT of thin super glue, buy it in small bottles.

If the smaller bottle dries out, you are only losing money on a smaller bottle.

The medium I buy at the dollar tree store, two small bottles for a dollar.

What "brand" CA do you prefer? And in what quantity?

You'll find your hobby stores name imprinted on Bob Smith CA.

Bob Smith makes all the different styles of CA glue.

The stuff from the Dollar Tree store is the original Super Glue brand.

And what do you think of this accelerator stuff? Is it trustworth? Does it harden at the risk of brittleness? Or other drawback?

I've never needed or used the accelerator. Thin CA dries pretty fast by itself. Medium CA just takes a longer time to dry.

His questions are in italics.

First up -

Super Glues get hard and brittle over time.

A older rocket constructed with Super Glue will have parts pop off during boost and on landing.

Don't use Super Glues to glue on fins, launch lugs or engine mounts.

In rocket construction it's only good for strengthening up a lip on a body tube, hardening a card stock shroud or lightly tacking some things in place.

Never use Super Glue on knots or shroud line knots. It runs up the line making it stiff and brittle.

IS there a shelf life to CA?

To extend it's life, keep it cold in the refrigerator.

Don't store it in the door, it might fall over and leak.

Is it known for leaking out of a plastic squeeze bottle?

Only when it's turned on its side! Don't let in fall over.

How often do you buy new CA, and in what quantity?

I buy small bottles as needed.

"Is there any way to revive an "old" or "Turned" bottle?"

Not that I know of.

What is best for rocketry? Thin? Thick? or other 'brand'?

I have thin and medium. I buy the thin in a small bottle at a hobby store.

Unless you use a LOT of thin super glue, buy it in small bottles.

If the smaller bottle dries out, you are only losing money on a smaller bottle.

The medium I buy at the dollar tree store, two small bottles for a dollar.

What "brand" CA do you prefer? And in what quantity?

You'll find your hobby stores name imprinted on Bob Smith CA.

Bob Smith makes all the different styles of CA glue.

The stuff from the Dollar Tree store is the original Super Glue brand.

And what do you think of this accelerator stuff? Is it trustworth? Does it harden at the risk of brittleness? Or other drawback?

I've never needed or used the accelerator. Thin CA dries pretty fast by itself. Medium CA just takes a longer time to dry.

Monday, October 26, 2015

Estes QCC Explorer Build Part 13, Nose Cone / Nozzle Prep

This is a LONG blow molded nose cone, 8" exposed from shoulder edge to tip.

The nozzle is molded on at the base.

The molding seams were pretty clean on this one, but will still need some filling.

The raised seam was reduced about half way down with 220 grit on a block. The remaining "trench" will be filled with medium CA glue.

Run a bead of medium CA down the seam using the ridge as a guide for the glue nozzle.

Only apply down one side seam and set up so the wet glue line can dry facing up. Keep the nose cone in a horizontal position, this glue will run!

When totally dry, apply a bead line of glue down the other side seam.

A heavy bead of CA glue will take a while to dry.

After the glue is dry, sand to surface with 220 grit on a block.

It's easy to cut the nozzle off the back of the nose cone.

The cut notches running around the nozzle are wide and the knife stays in easily. As always, don't try to cut through with one pass. Use several lighter cut passes.

The plastic wall thickness is not consistent. Be ready, your knife could cut through when you may not expect it.

I couldn't find this step in the directions, it's on the first page to the right of the parts drawing.

Ribbed Streamers TIP

"Ribbed streamers ... Well here's more insider info: Little old Special effects magic there!

"Ribbed streamers ... Well here's more insider info: Little old Special effects magic there!If it's real Shiny Sparkly Mylar it's from the party store Gift wrapping. Makes perfect streamers. Bright and reflective in the air and on the ground in the tall grass!

Crimping is done with a paper crimper. Make it by the mile!"

http://www.joann.com/fiskars-paper-crimper/4121422.html

Thanks Dave! A tool like this might also be useful for some corrugated wraps.

Sunday, October 25, 2015

Launch! Schoolyard Soccer Field, October 24, 2015

As soon as it was light enough, I headed over to the schoolyard at about 7:30 a.m. It's cool out with no winds - perfect.

I haven't flown the carded downscale Estes WOLVERINE since 2011.

It was prepped with an engine that Lonnie B. gave me. It was an old Centuri 13mm, a 1/2 A4-3m, dated 7-25-75.

I held the button down for two seconds before it took off. I would estimate the apogee at 200'.

The engine burn was fine and the streamer ejected. The boost had a tight corkscrew, typical for this small rocket. I think the small front sub fins throw it off a bit.

Next up was a favorite, the Quest ESCORT AS-1.

It had the normal Quest A6-4 engine and boost reached an estimated 250'.

Full parachute and no damage on recovery.

This was it's 17th flight, I might retire it and make another.

You can't go wrong with a Estes RED MAX.

Low and slow enough with an Estes B6-4 to 275'.

A textbook flight and and I caught it before it hit the wet grass.

This was one of the first rockets I put together when I got back into the hobby. My first attempt at cloning wasn't correct so it was rebuilt and repainted. It's sturdy and should be around for a long time.

Another favorite is the Dr. Zooch SLS.

With an Estes B6-4 it reached an estimated 275'.

There was a slow roll during boost.

This was my second catch of the day. I always try to grab the shock cord. I think most damage occurs when the rockets hit the ground.

I usually launch the small ones first but saved the Estes MOSQUITO for last. I thought my eyes might be "tuned up" by then to follow it after ejection.

I usually launch the small ones first but saved the Estes MOSQUITO for last. I thought my eyes might be "tuned up" by then to follow it after ejection.

The 1/4A3-3t engine got it to 275' but being so small it looks like it reached 750'.

At ejection I thought I was watching the rocket but it was falling too fast. I was following the ejected engine. I looked toward the horizon and heard a small "thud".

After five minutes of searching I found it 50' from the launcher tripod, nose first buried in the dirt. It was stuck in the opposite direction I was initially looking.

Featherweight "tumble" recovery? No. It nosed in and aerated the grass.

Launch on low cut grass and never, ever paint these things green.

Five up, five recovered with no damages. I almost lost the Mosquito.

I haven't flown the carded downscale Estes WOLVERINE since 2011.

It was prepped with an engine that Lonnie B. gave me. It was an old Centuri 13mm, a 1/2 A4-3m, dated 7-25-75.

I held the button down for two seconds before it took off. I would estimate the apogee at 200'.

The engine burn was fine and the streamer ejected. The boost had a tight corkscrew, typical for this small rocket. I think the small front sub fins throw it off a bit.

Next up was a favorite, the Quest ESCORT AS-1.

It had the normal Quest A6-4 engine and boost reached an estimated 250'.

Full parachute and no damage on recovery.

This was it's 17th flight, I might retire it and make another.

You can't go wrong with a Estes RED MAX.

Low and slow enough with an Estes B6-4 to 275'.

A textbook flight and and I caught it before it hit the wet grass.

This was one of the first rockets I put together when I got back into the hobby. My first attempt at cloning wasn't correct so it was rebuilt and repainted. It's sturdy and should be around for a long time.

Another favorite is the Dr. Zooch SLS.

With an Estes B6-4 it reached an estimated 275'.

There was a slow roll during boost.

This was my second catch of the day. I always try to grab the shock cord. I think most damage occurs when the rockets hit the ground.

I usually launch the small ones first but saved the Estes MOSQUITO for last. I thought my eyes might be "tuned up" by then to follow it after ejection.

I usually launch the small ones first but saved the Estes MOSQUITO for last. I thought my eyes might be "tuned up" by then to follow it after ejection.The 1/4A3-3t engine got it to 275' but being so small it looks like it reached 750'.

At ejection I thought I was watching the rocket but it was falling too fast. I was following the ejected engine. I looked toward the horizon and heard a small "thud".

After five minutes of searching I found it 50' from the launcher tripod, nose first buried in the dirt. It was stuck in the opposite direction I was initially looking.

Featherweight "tumble" recovery? No. It nosed in and aerated the grass.

Launch on low cut grass and never, ever paint these things green.

Five up, five recovered with no damages. I almost lost the Mosquito.

Estes QCC Explorer Build Part 12, Intake Notch Fix! TIP

I had seen Squadron Putty mentioned in the forums.

Most use it to fill seams in nose cones. I use medium CA glue to fill nose cone mold seams.

The Squadron Putty contains Toluene, a solvent that breaks down the plastic and allows the filler to bond to the nose cone plastic.

I thought I'd give it a try on the QCC intakes.

The CWF is water based and wouldn't stick and stay in the notch recesses. The CA glue used to assemble the intakes had sealed all the notch areas.

The solvent in the white Squadron Putty stayed in the shallow intake notches!

The upper picture shows the putty applied, spread out using the flat side of my knife.

The inset is the same area after sanding with 400 grit.

The putty dries quickly and sands easily. Most important, it stayed in the notch cracks and shallow recesses over the dried CA glue.

I had chose the white Squadron Putty over the original formula green putty. The white putty will be easier to cover with color spray coats.

Most use it to fill seams in nose cones. I use medium CA glue to fill nose cone mold seams.

The Squadron Putty contains Toluene, a solvent that breaks down the plastic and allows the filler to bond to the nose cone plastic.

I thought I'd give it a try on the QCC intakes.

The CWF is water based and wouldn't stick and stay in the notch recesses. The CA glue used to assemble the intakes had sealed all the notch areas.

The solvent in the white Squadron Putty stayed in the shallow intake notches!

The upper picture shows the putty applied, spread out using the flat side of my knife.

The inset is the same area after sanding with 400 grit.

The putty dries quickly and sands easily. Most important, it stayed in the notch cracks and shallow recesses over the dried CA glue.

I had chose the white Squadron Putty over the original formula green putty. The white putty will be easier to cover with color spray coats.

Saturday, October 24, 2015

Estes QCC Explorer Build Part 11, First Paint on Intakes

I thought I filled all the seams and notches with CWF and sanded primer filler! Obviously not.

These intake tab notches are hard to get smooth!

On the sides you can still see some of the tab notches.

Oh boy! - more filler and sanding.

EDIT: I've got to be honest. I got so frustrated trying to get the intakes smooth I set the model aside for six months.

Every built QCC model I've seen has tab notches showing through the paint.

Sometimes I take a break from a model and hope a solution presents itself.

I found a "fix"! See the next blog post.

Okay, What Is It?

Here's the (very) rough parts for an upcoming project.

The pictured nose cones will be trimmed and shortened. The shoulders will remain the same.

It will be used with the tube and fins from a recent, re-released kit.

Any ideas?

Friday, October 23, 2015

Estes QCC Explorer Build Part 10, Fitting the Intake Contour

Wrap some 220 grit around the body tube to sand the bottom of the intakes to match the curve of the body tube.

The upper intake is before,

The lower intake is the fit against the BT-60 body tube after contour sanding.

Keep an eye on the back of the intake when sanding.

All the intakes should end up at the same height at the front and rear.

The picture shows a good fit of the intake rear. This fit won't require any more than a fillet of Titebond M&TG for a fillet.

The upper intake is before,

The lower intake is the fit against the BT-60 body tube after contour sanding.

Keep an eye on the back of the intake when sanding.

All the intakes should end up at the same height at the front and rear.

The picture shows a good fit of the intake rear. This fit won't require any more than a fillet of Titebond M&TG for a fillet.

Magazine Rant

I got a letter from one of the airlines telling me I'd lose my accumulated frequent flyer miles after the first of the year. But I could redeem them for "Free" magazine subscriptions!

The trouble was, there wasn't many magazines I was interested in.

One of the few titles I knew was "People". But, the last time I was at the dentist office I didn't recognize any of the "People" in the magazine.

I read the descriptions and chose "Details" magazine.

The description implied: "A must-read for any man who wants to stay on top of current issues, while improving every facet of his personal life."

Instead I got a magazine that had 25 pages of ads before even reaching the Table Of Contents.

A fashion magazine? There were ads for expensive watches and groups of men in plaid jackets blankly staring at the camera. And, pages of men in their underwear.

I'm no prude, but I felt creepy paging through it.

I found the contact number online and called to cancel the subscription.

The call center was in Iowa. Iowa? I would expect this magazine to be home-based in New York.

I explained to the operator that the magazine was not for me.

She replied: "Well, it is very "Metro".

"Metro? That's the new word, I guess.

I asked her to cancel my subscription.

Save the trees! That, or print something worthwhile.

That reminds me, I'd better re-up my subscription to Consumer Reports.

The trouble was, there wasn't many magazines I was interested in.

One of the few titles I knew was "People". But, the last time I was at the dentist office I didn't recognize any of the "People" in the magazine.

I read the descriptions and chose "Details" magazine.

The description implied: "A must-read for any man who wants to stay on top of current issues, while improving every facet of his personal life."

Instead I got a magazine that had 25 pages of ads before even reaching the Table Of Contents.

A fashion magazine? There were ads for expensive watches and groups of men in plaid jackets blankly staring at the camera. And, pages of men in their underwear.

I'm no prude, but I felt creepy paging through it.

I found the contact number online and called to cancel the subscription.

The call center was in Iowa. Iowa? I would expect this magazine to be home-based in New York.

I explained to the operator that the magazine was not for me.

She replied: "Well, it is very "Metro".

"Metro? That's the new word, I guess.

I asked her to cancel my subscription.

Save the trees! That, or print something worthwhile.

That reminds me, I'd better re-up my subscription to Consumer Reports.

Thursday, October 22, 2015

Estes QCC Explorer Build Part 9, Intake Ends and Edges

This aluminum sanding block doesn't have sandpaper wrapped over the edges. You can sand right into some corners, like on the underside of the intakes.

The inside walls on the open front end of the intakes were filled before it was glued together.

Looking inside the left intake you can see two open slots.

I tried to fill the slots with small pieces of balsa. When all is finished I'll know if it was worth the effort.

I added some Titebond M&TG fillets using a Q-tip to spread and smooth them out.

Wednesday, October 21, 2015

Cherokee D Auction Finishing Up!

The finished Cherokee D auction is coming to a close soon!

Check it out at: CLICK HERE

Stop by and make a bid . . .

Estes QCC Explorer Build Part 8, Intake Assembly

This is the front and rear of the intakes assembled. The only balsa grain that has been filled so far is the front interior of the intake.

There are some recessed tab areas throughout.

On the right I circled some of the deeper areas. With the CA glue in the recess, CWF probably won't stay in when sanded down.

I cut some thin slivers of 1/16" balsa and CA'd them in place.

I did the same thing under the center tab at the intake front. The tab was too short to sand flush.

The picture shows a balsa sliver fill after sanding.

Under that, I've yet to sand the bent "V" leading edge round.

You could use CWF to fill the recessed tab areas.

Another way is to apply a tiny bit of CA in the recess then quickly sand over the glued hole. Sanding "dust" will stick to the CA and fill the square hole. But, you've got to be quick.

The CA glue can gum up the sandpaper though.

Be ready - These intakes take about 30 minutes each to glue together.

It takes quite a while longer to adequately fill all the gaps and seams.

Subscribe to:

Comments (Atom)