Here's an example of what can happen when trying to research a complex clone build -

I knew there was clay weight added to the nose cone, but didn't know how much the kit clay weighed.

I went to the old Semroc.com website and clicked on the "Classics" button on the right side.

Scroll down to 1980 - 1981 to find the Dragon Ship 7.

If there is small parts icons in a blue box to the left, click on that and you'll get a parts list.

To see the parts page -

CLICK HERE The clay weight is near the bottom -

Semroc says the part name is CB-M4. Apparently "C.B." is an abbreviation for

Clay

Balance. The CB-M4 clay weight shown here is 6g or .21 oz.

Next, the old Estes Custom Parts Catalog

CLICK HERE but couldn't find any clay weights. There are lead weights and washer weights with the prefix - NCW-1, 2, 3 and 4. If the numbers are still consistent, the clay CB-M4 weight should be .354 oz.

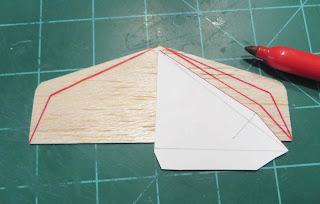

On the left is the 6g or .21 oz. clay weight. It seems pretty small.

There are small forward fins on this model, I'd feel better if there were more nose weight.

On the right is the NCW-4 weight equivalent of .35 oz. I'll play it safe and go with the larger nose weight.

The current Estes Clay Nose Cone Weight package #3180, contains 10 pats of clay, each one weighs approximately .25 oz.

Sometimes cloning is a guessing game. You hope the parts list and online scans are correct. Maybe the Semroc parts page listed the wrong nose weight?

EDIT: Check BAR Geezer's comment below. The #82560 clay weight ends up being 6 grams or .21 oz.! After the finished weigh-in, I may launch this one with a C6-3.