Before gluing the plywood centering rings in place,

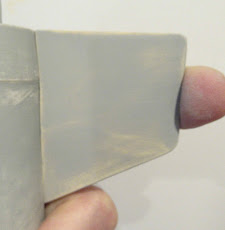

Check the fit of the fins in the fin lock rings.(This picture is from an earlier build and shows the previous fibre centering rings.)

Before gluing the rings in place,

Double check that the fin is running straight down the tube.

The two rings on the far end are just slid on the tube to keep track with five builds going on.

The cooling mesh baffle is stretched out to 6" in length.

The mesh is slid into the top of the motor mount tube.

The top edge of the tube is slit so the baffle shoulder piece can slide in.

Four 1/4" slits are made, spaced 90 degrees apart. Notice the pencil line at 1/4" down from the top of the tube.

Using a single edge razor blade, you can cut two 1/4" lines directly opposite to each other.

Glue the shoulder piece in with medium CA glue.

The screw eye is screwed in the top hole of the shoulder.