Home print water slide decals aren't the same as kit decals. The soak times and transfers are different.

I typically soak a home print decal for about 30 seconds in warm water. Then set the wet decal on a paper towel while it continues to release.

In my experience, home printed decals don't slide off the backing paper as easy as kit decals.

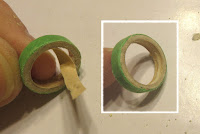

On the right I'm rubbing up on the bottom and then down on the top to be sure it is releasing from the backing. I might dip the decal in the water again if it doesn't move a little off the backing.

Always wet the area where the decal will go with a wet finger leaving water on the surface.

Be careful setting down a home print decal not allowing it to fold back onto itself. Krylon clear coat acrylic can be stretchy. Don't allow these decals to stretch, the ink could crack.

Notice the edges of the decal don't want to lay down smoothly. At this point use a paper towel to blot up most of the water.

Roll (don't wipe) a wet Q-tip over the decal from the center out to the sides to set down the edges.

I don't spray a clear coat over the entire model to seal the decals. Overall acrylic clear coats can get sticky in humid weather.

The clear coat is applied to just the decal and decal edges with a Q-tip. Dip a Q-tip in Future floor finish then dab off the excess. Roll the Q-tip over the decal.

Tuesday, February 28, 2017

Estes Skydart II #3229 Build, Part 6, Wing Piece Fit

When dry fitting, I was surprised by the gap between the wing pieces. I didn't over sand the sides when cleaning up the burnt edges.

The center triangle piece was glued on first using the burnt in center alignment line.

Here's a close up of the stepped edge. The back end will be sanded even with the edge of the triangular piece.

With the curved leading edge matched at the top, the two-piece rudder wasn't even on the root edge. For gluing flat on the wing you'll want the bottom edges even.

It'd be best to glue the bottom edge flat then sand and match up the curved leading edge after the glue dries.

Monday, February 27, 2017

Quest Q-Jets Engines Introduced at NARCON

From a February 25 Rocketry Forum post by Mr. G:

"Here is a sneak peek on the coming single use composite A-D motors from Aerotech/Quest.

Gary said two had been certified but they won't release anything until all have completed testing. The propellent for all is Black Jack or Black Max to be confirmed with more news after the NARCON Manufacturers Presentations at 5pm ET today."

To read the thread, CLICK HERE

"Here is a sneak peek on the coming single use composite A-D motors from Aerotech/Quest.

Gary said two had been certified but they won't release anything until all have completed testing. The propellent for all is Black Jack or Black Max to be confirmed with more news after the NARCON Manufacturers Presentations at 5pm ET today."

To read the thread, CLICK HERE

Two Rocket Auctions on EBAY

The finished NIKE GOON and

Estes SOLAR WARRIOR are listed on EBAY.

To bid on the Nike Goon, CLICK HERE

To bid on the Solar Warrior, CLICK HERE

Stop by, make a bid and support the blog!

Estes Skydart II #3229 Build, Part 5, Elevator Hold Down

The original kit used a pre-bent wire to hold the elevator down during boost.

The new kit uses three pieces of laser-cut balsa. Here's a dry fit of the assembly.

I don't sand these down before gluing. The will be sanded flat and even after the glue is dry.

Glue is applied to the flat sides of the two vertical pieces. Check the bottom fit against the BT-20 pop-pod tube.

Clamp the two pieces together for drying.

TIP: Don't sand down the rounded side that glues to the BT-20 pop pod tube. The fit is correct to hold down the elevator without sanding any of the burnt curve. Later I ended up having to build up the curve to make it a bit higher.

The top horizontal "T" shaped piece is glued on and all three are sanded clean together.

The nylon screw is screwed into the small hole. The threads on the screw will cut threads into the balsa. Remove the screw.

The screw threads are strengthened with a drop of CA glue set into the hole.

Before the glue has a chance to dry, soak up any excess with a quick turn of a Q-tip in the hole.

After that dries, reinsert in the nylon screw again to check the fit. You should end up with a very strong hole with clean threads.

The new kit uses three pieces of laser-cut balsa. Here's a dry fit of the assembly.

I don't sand these down before gluing. The will be sanded flat and even after the glue is dry.

Glue is applied to the flat sides of the two vertical pieces. Check the bottom fit against the BT-20 pop-pod tube.

Clamp the two pieces together for drying.

TIP: Don't sand down the rounded side that glues to the BT-20 pop pod tube. The fit is correct to hold down the elevator without sanding any of the burnt curve. Later I ended up having to build up the curve to make it a bit higher.

The top horizontal "T" shaped piece is glued on and all three are sanded clean together.

The nylon screw is screwed into the small hole. The threads on the screw will cut threads into the balsa. Remove the screw.

The screw threads are strengthened with a drop of CA glue set into the hole.

Before the glue has a chance to dry, soak up any excess with a quick turn of a Q-tip in the hole.

After that dries, reinsert in the nylon screw again to check the fit. You should end up with a very strong hole with clean threads.

Sunday, February 26, 2017

Estes Skydart II #3229 Build, Part 4, Balsa Prep

The large, flat wing is assembled using four pieces. The laser cut sides are a slight wedge shape. One side of the cut is wider than the other. To see the difference, check the widths of the laser cut lines on one side, then flip over the sheet and check the lines on the other side.

If the wing and rudder glue joints are going to be tight and clean the laser cut 'wedges lines will have to be squared up.

On the left you can see the center alignment line burned into the main wing piece.

I found in interesting that the Estes instructions showed the Great Planes Easy Touch sanding block in their illustrations. This is the only sanding block I use.

Don't sand too much off the elevator sides. In the picture at the top you can see how it is cut right out of the wing piece. Sand off just enough to square it up. You don't want it too loose in the wing slot.

Don't sand too much off the elevator sides. In the picture at the top you can see how it is cut right out of the wing piece. Sand off just enough to square it up. You don't want it too loose in the wing slot.

The inset picture shows another reason for cleaning up the laser cut balsa. Sometimes you find a rough or uneven edge as if the laser were "chattering" down the cut line. Personally, I think glue joints might be weaker on burnt wood.

If the wing and rudder glue joints are going to be tight and clean the laser cut 'wedges lines will have to be squared up.

On the left you can see the center alignment line burned into the main wing piece.

I found in interesting that the Estes instructions showed the Great Planes Easy Touch sanding block in their illustrations. This is the only sanding block I use.

Don't sand too much off the elevator sides. In the picture at the top you can see how it is cut right out of the wing piece. Sand off just enough to square it up. You don't want it too loose in the wing slot.

Don't sand too much off the elevator sides. In the picture at the top you can see how it is cut right out of the wing piece. Sand off just enough to square it up. You don't want it too loose in the wing slot.The inset picture shows another reason for cleaning up the laser cut balsa. Sometimes you find a rough or uneven edge as if the laser were "chattering" down the cut line. Personally, I think glue joints might be weaker on burnt wood.

Nike Goon Follow-Up With Decals

Did you ever finish a model and wish you had done a few things differently?

As I usually do, I made two of the Nike Goons. One to fly, the other to sell on Ebay.

On the left is the first try using the black trim. This is the model I've flown twice already, I'm keeping this one.

On the right is the second trimmed Nike Goon. The top roll pattern is a bit taller. The rounded rectangles aren't as wide, a little more of the white is showing. A few subtle changes and the second model looks better.

And finally, two weeks later I printed up some decals.

The original Estes Nike X kit had a U.S. ARMY decal going vertically down the body. This one got a U.S. GOONY in red with a thin black outline. Sometimes adding an outline to letters makes it visually stand out.

The two white right side fins have a black NIKE G decal. Not a lot of decals but it does finish it off well.

As I usually do, I made two of the Nike Goons. One to fly, the other to sell on Ebay.

On the left is the first try using the black trim. This is the model I've flown twice already, I'm keeping this one.

On the right is the second trimmed Nike Goon. The top roll pattern is a bit taller. The rounded rectangles aren't as wide, a little more of the white is showing. A few subtle changes and the second model looks better.

And finally, two weeks later I printed up some decals.

The original Estes Nike X kit had a U.S. ARMY decal going vertically down the body. This one got a U.S. GOONY in red with a thin black outline. Sometimes adding an outline to letters makes it visually stand out.

The two white right side fins have a black NIKE G decal. Not a lot of decals but it does finish it off well.

Saturday, February 25, 2017

Estes Skydart II #3229 Build, Part 3, Pop Pod Assembly

Combined, the five nose weight washers weigh 0.57 oz.

Here's the thick 5/50 centering ring even with the top of the short BT-5 tube.

The washer weights butt up against it. A 5/20 ring glues against the bottom of the weight stack.

The last 5/20 ring is glued even with the low end of this short BT-20 tube

Here's another place where the re-issue kit is different. Two Mylar retaining rings are glued around the engine hook.

Here's another place where the re-issue kit is different. Two Mylar retaining rings are glued around the engine hook.The upper Mylar ring is glued under the top of the hook. The middle Mylar ring is glued over the hook as normal.

A 20/50 ring is glued against the upper bend of the engine hook.

Here's the finished pop-pod assembly.

On the top is the low engine end, below that the upper weighted washer assembly is glued in place.

On the reissue kit the ejection charge passes through the top of the pop pod. On the original design the top of the pod was blocked. The ejection charge went through two holes punched in the sides of the pod.

Thick Shroud Line Attachment -- TIP

I never attach parachute shroud lines directly to the nose cone. If the nose cone passes through any two lines your parachute lines are tangled. I'll add a longer shock cord and tie the cute on about 1/3 the way down (and away) from the nose cone.

Snap Swivels are about 10 for $1.00 pack at WalMart. Save yourself from tangles and be ready to easily switch out a smaller parachute when the winds are up.

The shroud lines on my Big Betty kit were too thick to go through the small eyelet on a snap swivel. I could eventually get all three loops through, but sometimes it's easier just to tie them on the eyelet using some thick rug and button thread.

The outside shroud line loop is tied onto a length of strong thread. Tie the thread to the center point of the shroud line.

The strong thread is tied to the center point of the second center shroud line loop, next to and beside the first one already tied on.

The picture shows the third shroud line loop being slid down the strong thread. At the apex of the "bend" you can see the center mark made with a marker.

The third shroud line is tied to the thread. I doubled over the thread through the loops again for strength.

You now have two loose ends to tie onto the small swivel eye.

No tangles and the swivel is ready to attach to a loop tied on the shock cord.

This is the same method I used to tie the parachutes to snap swivels on the Estes Saturn V build.

The shroud lines in the reissue kit were also too thick to go through the swivel eyelet.

Snap Swivels are about 10 for $1.00 pack at WalMart. Save yourself from tangles and be ready to easily switch out a smaller parachute when the winds are up.

The shroud lines on my Big Betty kit were too thick to go through the small eyelet on a snap swivel. I could eventually get all three loops through, but sometimes it's easier just to tie them on the eyelet using some thick rug and button thread.

The outside shroud line loop is tied onto a length of strong thread. Tie the thread to the center point of the shroud line.

The strong thread is tied to the center point of the second center shroud line loop, next to and beside the first one already tied on.

The picture shows the third shroud line loop being slid down the strong thread. At the apex of the "bend" you can see the center mark made with a marker.

The third shroud line is tied to the thread. I doubled over the thread through the loops again for strength.

You now have two loose ends to tie onto the small swivel eye.

No tangles and the swivel is ready to attach to a loop tied on the shock cord.

This is the same method I used to tie the parachutes to snap swivels on the Estes Saturn V build.

The shroud lines in the reissue kit were also too thick to go through the swivel eyelet.

Friday, February 24, 2017

Estes Skydart II #3229 Build, Part 2, Centering Ring Prep

The thick ring didn't have flat sides. Considering it sits flat against the washer weights I sanded the raised rings even and smooth.

The cut of the engine mount tube wasn't clean. This was also evened out with the sanding block.

I don't like to force centering rings over body tube ends. These rings had some raised crimps on the inside and wouldn't easily fit over the internal BT-20.

First, the end of my X-Acto handle was rolled over the inside to press the crimps down. The ring still wouldn't fit over the tube.

The rings were then peeled to enlarge the inside diameter.

If you have to do this, try to lift as little of the paper as you can. It's easy to remove too much.

One ring fit well, the other ended up too loose. The inset picture shows the ring of glue on the inside to build up the diameter. Let the glue fully dry before thinking about gluing it in place.

Thursday, February 23, 2017

Estes Skydart II #3229 Build, Part 1, Parts

What's really different is the pop pod assembly and all the centering rings.

Parts of interest: On the top is the self-adhesive clear tape for the elevator hinge.

There are five washer weights. Also in the bag is the nylon elevator adjustment screw.

White elastic to raise the elevator. In the middle of the elastic is a very thin engine block.

In the lower center is the very thick top centering ring. This ring is glued at the top of the pop pod over the stacked washer weights.

A separate parts list is included.

Hang on to it, it comes in handy when gluing up the pop pod assembly.

Don't lose the nylon screw! It'd be hard to find a replacement. I kept it in a small bag until it was turned into the elevator set arm.

Knife Blade Thickness? TIP

Kit instructions sometimes tell you to simply use a straight edge when cutting out fins or card stock. Simply setting a the strait edge along the cut line doesn't account for the thickness of the knife blade.

Here I'll be cutting a strait line between two marks in card stock. (You can certainly use this tip on balsa.)

Don't set the strait edge down yet.

First, set your knife blade right on the cut line. You can punch the tip into the card stock.

Leave the knife in the card stock line. Then slide the strait edge up to and against the knife blade.

Here you have made a slight space allowance for the thickness of the knife blade.

Look at the space between the strait edge and line on the right side.

Adjust the strait edge position on the left until it matches the spacing on the right.

Now you can cut the entire line starting from the left and going to the right. You are guaranteed your cut is exactly on the cut line.

Here I'll be cutting a strait line between two marks in card stock. (You can certainly use this tip on balsa.)

Don't set the strait edge down yet.

First, set your knife blade right on the cut line. You can punch the tip into the card stock.

Leave the knife in the card stock line. Then slide the strait edge up to and against the knife blade.

Here you have made a slight space allowance for the thickness of the knife blade.

Look at the space between the strait edge and line on the right side.

Adjust the strait edge position on the left until it matches the spacing on the right.

Now you can cut the entire line starting from the left and going to the right. You are guaranteed your cut is exactly on the cut line.

Wednesday, February 22, 2017

Estes Skydart II #3229 Build, Background

This will be a fun build - The Astron Skydart II. It first appeared in the 1972 Estes catalog as K-57.

Larry Renger was the designer. He also developed the classic Falcon Boost Glider.

Pop Pod boost gliders were pretty new then. The first Citation Bomarc and was a pop pod glider.

With a "pop-pod" glider the internal engine tube ejects and descends by parachute. The eject pod allows the elevator to raise and the model glides in.

The online instructions are a different format for Estes and worth a look. To see them, CLICK HERE. There are differences between the original and re-issued kit.

The original kit hard cardstock formed nacelles on the underside of the wing. The new kit uses a split BT-50 tube.

The original kit included a pre-bent elevator retainer wire. The current kit uses three glued together pieces of balsa.

Larry Renger was the designer. He also developed the classic Falcon Boost Glider.

Pop Pod boost gliders were pretty new then. The first Citation Bomarc and was a pop pod glider.

With a "pop-pod" glider the internal engine tube ejects and descends by parachute. The eject pod allows the elevator to raise and the model glides in.

The online instructions are a different format for Estes and worth a look. To see them, CLICK HERE. There are differences between the original and re-issued kit.

The original kit hard cardstock formed nacelles on the underside of the wing. The new kit uses a split BT-50 tube.

The original kit included a pre-bent elevator retainer wire. The current kit uses three glued together pieces of balsa.

Tuesday, February 21, 2017

Nike Goon, Finished

This was a fun build. I didn't know if the complicated trim vinyl would work.

There are still some water slide decals to go on, a vertical red U.S. GOONY on the upper body and maybe a NIKE G on two lower fins. I won't use up a full sheet for something this small.

The Goonys are great small field flyers with A8-3 and B6-4 engines.

Why A Break-Off Blade Knife?

Think about it. When do you normally change a #11 X-Acto blade? When the tip breaks off. Did you ever notice the edge below the broken tip seems sharp?

90% of knife use in rocket building is cutting laser cut fins free from the wood sheet. Why waste a blade that costs $1.00 each on laser cut fins? A break-off blade section is just pennies per segment.

Pop off a dulled segment on a break-off blade knife and you've got a new sharp edge. Save some money - Use your X-Acto knife and #11 blades for the complex curves and tight cutting.

The knife on the right isn't one of those cheap break-off handles. It's a 9mm blade handle made by Olfa, the XA-1. It sells at Home Depot for under $5.00. The blades can feel loose in the cheaper bargain bin utility knifes.

90% of knife use in rocket building is cutting laser cut fins free from the wood sheet. Why waste a blade that costs $1.00 each on laser cut fins? A break-off blade section is just pennies per segment.

Pop off a dulled segment on a break-off blade knife and you've got a new sharp edge. Save some money - Use your X-Acto knife and #11 blades for the complex curves and tight cutting.

The knife on the right isn't one of those cheap break-off handles. It's a 9mm blade handle made by Olfa, the XA-1. It sells at Home Depot for under $5.00. The blades can feel loose in the cheaper bargain bin utility knifes.

Monday, February 20, 2017

Nike Goon Build, Part 10, Added Paint Weight?

I'm a sport flyer and don't pay much attention to the weight of paint.

Daniel Petrie (The Rocket N00b) did some great articles about paint and how the weight can effect performance. To visit his blog and those write-ups:

http://rocketn00b.blogspot.com/2016/11/the-weight-of-paint.html

http://rocketn00b.blogspot.com/2016/11/the-weight-of-paint-part-2-so-why-paint.html

http://rocketn00b.blogspot.com/2016/11/the-weight-of-paint-part-3-surface.html

http://rocketn00b.blogspot.com/2017/01/the-weight-of-paint-part-4-painting.html

Daniel Petrie (The Rocket N00b) did some great articles about paint and how the weight can effect performance. To visit his blog and those write-ups:

http://rocketn00b.blogspot.com/2016/11/the-weight-of-paint.html

http://rocketn00b.blogspot.com/2016/11/the-weight-of-paint-part-2-so-why-paint.html

http://rocketn00b.blogspot.com/2016/11/the-weight-of-paint-part-3-surface.html

http://rocketn00b.blogspot.com/2017/01/the-weight-of-paint-part-4-painting.html

This got me thinking about how much weight my paint jobs could add. I probably lay the paint on thicker than most. I paint my rockets for a few good reasons. They are stronger and sealed after proper painting. If you ever had a rocket waiting on a launcher and a rain shower rolls through, you'll be glad the model is painted.

The 12" parachute and shock cord are installed for the weigh-in.

The sanded primer and assembled Nike Goon weighed in at 1.56 oz.

Two light white coats were sprayed and smooth sanded. The final heavier coat was sprayed. Now the model weighs 1.63 oz, ready for trim.

After all the vinyl trim was in place the final weight is 1.70 oz.

So the paint and trim added just 0.14 oz. Not bad!

The Baby Bertha face card says it should weigh close to 1.90 oz. (Who knows if this Estes specification is the shipping weight, assembled "naked" weight or painted model weight.)

My finished model came in 0.20 oz. less than the Baby Bertha. I would think it would have weighed a bit more.

Folding Parachutes TIPS, Part 2

Here's how I'd pack a 18" chute in a shorter BT-60 sized model.

Sometimes a packed chute can't be long and narrow. On a squatty model you won't have room for wadding, parachute and the nose cone shoulder.

You still want the parachute to eject like a piston without any "blow-by" of the ejection charge.

As mentioned earlier, always open and air out your parachutes right before launch. Sprinkle some talcum powder on the chute before packing so it won't stick together.

TIP: NEVER use talcum powder with corn starch! Corn starch is flammable.

After spiking the chute, fold into thirds. The parachute will pack shorter.

Fold the three-fold pack in half vertically, then in half again.

Wrap the shroud lines as shown in the previous post. Don't wrap the lines tightly.

TIP: As extra insurance to prevent any hot spot melts -

Cut a piece of sheet wadding down to about 3 1/2" square. Set the low end of the packed chute in the center of the square. Wrap the low end of the parachute with the wadding. Wrap the sides of the wadding up the chute.

It is important to cut the wadding square smaller. You want the wadding sheet to peel away from the parachute at ejection.

Sometimes a packed chute can't be long and narrow. On a squatty model you won't have room for wadding, parachute and the nose cone shoulder.

You still want the parachute to eject like a piston without any "blow-by" of the ejection charge.

As mentioned earlier, always open and air out your parachutes right before launch. Sprinkle some talcum powder on the chute before packing so it won't stick together.

TIP: NEVER use talcum powder with corn starch! Corn starch is flammable.

After spiking the chute, fold into thirds. The parachute will pack shorter.

Fold the three-fold pack in half vertically, then in half again.

Wrap the shroud lines as shown in the previous post. Don't wrap the lines tightly.

TIP: As extra insurance to prevent any hot spot melts -

Cut a piece of sheet wadding down to about 3 1/2" square. Set the low end of the packed chute in the center of the square. Wrap the low end of the parachute with the wadding. Wrap the sides of the wadding up the chute.

It is important to cut the wadding square smaller. You want the wadding sheet to peel away from the parachute at ejection.

Sunday, February 19, 2017

Folding Parachutes TIP, Part 1

A Patreon supporter asked about how I fold parachutes and what is my success percentage. Here's how I do it - My success rate is almost 100% with a rare melted spot.

Look at the instructions from the old Centuri Nike Smoke instructions.

Pretty vague - "Fold chute as shown below and insert". Where do the shroud lines go? That accordion five-fold seems strange.

Here's how to fold a parachute for a taller rocket with a smaller diameter tube. The packed chute will end up long and thin, or how to pack a 12" chute in a BT-20 tube.

Right before launching - Always open a plastic sheet parachute (air out) and dust with talcum powder.

"Spike" the parachute by pinching the center with the left hand fingers.

Make an "OK" circle with your right thumb and forefinger. Slide your hand down the canopy making the spike shape.

Fold the top half of the spike in half, the top is folded down to the bottom of the canopy.

Down the length of the chute fold vertically in half.

Fold vertically in half again.

Note the chute ends up tall and narrow for a better fit in a taller, thinner diameter rocket.

Wrap the shroud lines around the chute diagonally.

After about three wraps set the remaining lines lay vertically down the wrapped chute. More to come . . .

Look at the instructions from the old Centuri Nike Smoke instructions.

Pretty vague - "Fold chute as shown below and insert". Where do the shroud lines go? That accordion five-fold seems strange.

Here's how to fold a parachute for a taller rocket with a smaller diameter tube. The packed chute will end up long and thin, or how to pack a 12" chute in a BT-20 tube.

Right before launching - Always open a plastic sheet parachute (air out) and dust with talcum powder.

"Spike" the parachute by pinching the center with the left hand fingers.

Make an "OK" circle with your right thumb and forefinger. Slide your hand down the canopy making the spike shape.

Fold the top half of the spike in half, the top is folded down to the bottom of the canopy.

Down the length of the chute fold vertically in half.

Fold vertically in half again.

Note the chute ends up tall and narrow for a better fit in a taller, thinner diameter rocket.

Wrap the shroud lines around the chute diagonally.

After about three wraps set the remaining lines lay vertically down the wrapped chute. More to come . . .

Subscribe to:

Posts (Atom)