This annual list puts some of the blog builds in order of favorites from 10 to 1.

(This annual post it the tough one, it takes a few hours to gather info, pictures and links.)

These are the builds that were the high points this year.

Choices are my own based on the overall build experience and some flight performance.

Your favorites might be different!

Choices are my own based on the overall build experience and some flight performance.

Your favorites might be different!

No bad builds this year, all kits were well produced.

Another great MicroMaxx model from ASP!

A bit taller than most MMX rockets, still impressive altitude from the 1/8A motors.

To see the complete build: CLICK HERE

9. New Way Squared Red Max

A great take on the Estes classic.

A bit smaller than the BT-60 model.

The kit contains the white decals

To see the complete build: CLICK HERE

A BIG demo model. Graphics are fun but these are peel and stick. A bit hard to find the right matching shade of "red" for the nose cone.

To see the complete build: CLICK HERE

7 New Way Mars Snooper II

Another great New Way kit, this time a round tube clone of the second Mars Snooper design. It is on the right next to the Estes original.

To see the complete build: CLICK HERE

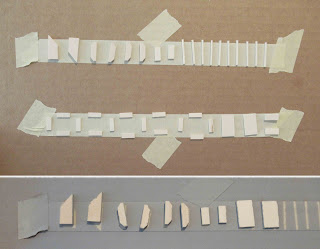

Six SRBs on this one!

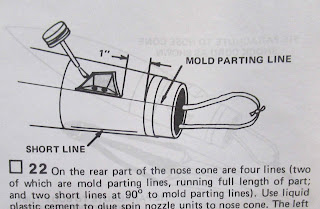

A few kit pieces may not match the parts list in the instructions.

A very impressive model, but lots of stickers.

To see the complete build: CLICK HERE

The countdown continues tomorrow!