CA glue (or Fabri-Tac glue) is set around the sides of the centering ring and front of the the body tube edge.

Line up the launch lug with the hole. The assembly is slid all the way forward into the shroud body making contact with the inside body walls.

The outside joints of the the launch lug are hit with medium CA glue.

The lug might look a little rough - see the next pictures to clean it up.

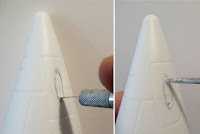

Using a new single edge razor blade, the launch lug is trimmed off matching the angle of the shroud body. It's best to cut the lug off a shade long and shave it down to the shroud body.

Note how the rough cut lug isn't a clean oval - yet.

Apply some CA glue with a Q-tip to harden it. Sand smooth.

Repeat if needed until you get a smooth rounded edge at the top and bottom.

Those pencil marks on the shrouds are where the low seam areas were filled with medium CA and sanded smooth.

Here's a final fit and smoothing of the lug in the hole.

Notice the lug wall at the bottom near the knife point. The lug wall looks wide because it was cut and smoothed at an angle.

If you take your time, you can end up with very little joint filling.