I've got a lot on my plate right now with contracted builds.

I'll take this one as far as I can, but can't guarantee a painted finished build.

Still, the sub-assemblies will be interesting . . .

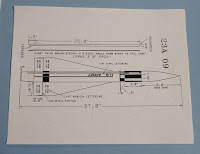

Here's what was in the bag -

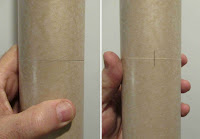

Two lengths of BT-80 tubing, the brown coupler is slid in the shorter length tube.

A length of 2" diameter tubing for inside the tail cone and surrounding the engine mount.

Lots of centering rings and engine mount parts.

Sheet balsa for fins and strips were included for the tunnels.

The instruction booklet was shown in the last post.

Here's that plastic Alpha style nose cone. It's been used before in the old Maxi Alpha and Colossus kits.

The "kit" also included a 3/16" launch lug.

The tri-fold shock cord mount looks small and feels too thin.

The kit supplied lug is on the left.

It looks like a plastic drinking straw that was spray painted to rough it up for better adhesion. I'll replace it with a stronger, standard 3/16" lug.

The supplied engine hook looks wider and flatter than a regular hook. It looks questionable and will be replaced.

Above the coupler is a parachute "shelf". It's not a baffle so the model would require wadding.

The shelf prevents the parachute and wadding from sliding down towards the bottom of the rocket at boost. The shelf helps keep the C/G forward for stability.