Here I'm listing some of the new products from the manufacturers. I finally got to listen to the presentation Sunday afternoon.

This blog is LPR based so most of my comments from the Manufacturers Forum will reflect that.

Click on the NAMES to go to their websites.

Central Storage - Everything needed stores in PVC tube built into launcher. Field tough controllers and launchers for LPR, Sport, MPR, HPR, TARC and STEM Education.

12 volt LiPo Battery

New PA-Zazz Public Address System. 8 ft. tall Horn Speaker stands. 150w RMS, 2 Channels

Working to combine both LOC and PML into a single website.

Integrating both LOC and PML parts and systems.

Now available:

Scorch - Vinyl décor

Corporal

Coming soon:

Artemis SLS - quite a lot of 3D printed parts, 29mm

Star Launch - Shrox design, 3 gliders on the low end.

USMX 2100 - 2.6" tube, sport flyer

Bring backs - First two of six NCR models before next December

4" diameter Phantom

4" diameter A14 Archer XL

Scale upgrade kit for Estes Doorknob

Durable 1/100 scale Apollo escape tower lattice

3D printed, tougher resin print

1/70 Apollo tower in the works

Upscale parts to convert a Big Red Max to a Citation Patriot

(Wraps from Sticker Shock)

First kit to be released this year:

FAI Tube Competition Kit (Parachute, Streamer & Helicopter Duration competitions)

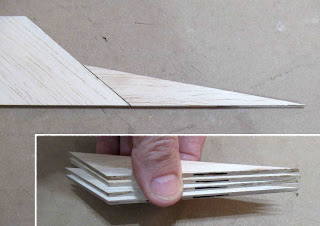

FAI Fin Jig

Fun to see a few of my builds. That's my Super Mars Snooper and Vesta Intruder.

Super Orbital Transport - upscale of the classic kit.

Coming:

B.O.S.S. Bill Simon Designer’s Series kit

Blue Origin Builder’s Kit, 18mm engine

Blue Origin New Glenn, for 2023

Space x 1/100 Falcon 9, clear plastic fin unit, display nozzles

Only available from the Estes and Space X websites

A3-2t and A3-6t engines, shipping in May

24mm “long” engine, “Somewhere between an E57 and an E65 A deep-core burning, black powder engine.” USPS shippable.

* Estes gets it’s balsa from Malaysia.

* Estes owns the MicroMaxx engine making machines, purchased from Quest. Possible MMX products in the future.

* Estes did purchase Goex Black Powder

60 kits are back in production

24mm Tres upscale

Gigabucks (Buckshot upscale) 24mm, different decors available

Coming:

Upscale Deuces Wild 3" diameter, two 29mm engines

Radial Velocity, 29mm, ring fin model with many strakes.

Smaller tri-motor version possible

Upscale Mudwasp, 24mm

Two possible models inspired by the Thunderbirds

New Scissor Wing Transport - Clone kit of the classic Estes kit.

40% off Excel Knives, blades and accessories for one month.

Upscale Super Blue Bird Zero in development.

Even larger Mars Snooper and Orbital Transport in development.

* Some balsa shortages. More 3D parts to be developed.

* Heavier walled Centuri style tubing used in larger kits.

New 13mm Astrobee D kit, BT-5 based, wire antennas $12.95 introductory price

A few large Wac Corporal 2.6" diameter kits are available

Again, this blog deals with LPR,

New 24mm x 95mm Q-Jets. White Lighting propellant E35 and F41 motors with 5, 8 or 11 second delays. Can ship using USPS with no hazmat fee. Available Spring 2022.

* A new 15,000 sq. ft. production facility

* New website combining Aerotech and Quest to be unveiled soon.