Oh, I'm tempted!

But I still have unopened kits left over from the last clearance sale.

I've given quite a few of them away, but the build pile is still pretty full.

But, knowing me, I'll probably pull the trigger on that loaded shopping cart before the Sunday deadline.

Saturday, November 30, 2019

Lawn Dart Rocketry SLAT/S Build, Part 6, Fitting the Ramjet Pieces

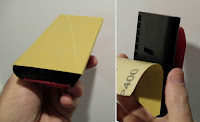

I didn't use the PDF pattern to cut the ramjet tube. I just guessed the angle, drew a line and cut off a wedge. The angle was smoothed with a sanding block.

Down the length of the the tube, a 3/4" width strip was cut out using the aluminum angle.

The inside edge was sanded smooth and flat.

The ramjet half nose cone was taken from my Odd'l Rockets F-104 kit parts.

Wrap some 220 grit around a smaller tube (than it will fit) and sand the concave curve on the underside.

The picture on the right shows a good fit on the BT-50H main tube.

Down the length of the the tube, a 3/4" width strip was cut out using the aluminum angle.

The inside edge was sanded smooth and flat.

The ramjet half nose cone was taken from my Odd'l Rockets F-104 kit parts.

Wrap some 220 grit around a smaller tube (than it will fit) and sand the concave curve on the underside.

The picture on the right shows a good fit on the BT-50H main tube.

I Wish They Didn't Do That - Part 4, Tri-Fold Shock Cord Mounts

I'm not a big fan of the Tri-Fold Shock Cord Mounts. They certainly work, it's just not my personal preference.

Years back, the shock cord mount provided in a kit was on a separate piece of 65 lb.card stock, not printed on the 20 lb. paper instruction sheet. To use this mount you cut up the instructions. You could always make a copy and keep the instruction sheet intact.

I could see a 20 lb. paper mount used in small tubes. A Tri-Fold is bulky and might block the ejection of the chute or streamer. You want the finished Tri-Fold mount to be flat and tight against the inside wall of the tube.

I'd rather see a thicker card stock used in larger models, BT-55 and above.

I drew up a sheet of different size Tri-Fold Shock Cord mounts you can print on 65 lb. card stock.

Patreon members can send an email to

oddlrockets@bellsouth.net and request the Tri-Fold Shock Cord Mount PDF

Years back, the shock cord mount provided in a kit was on a separate piece of 65 lb.card stock, not printed on the 20 lb. paper instruction sheet. To use this mount you cut up the instructions. You could always make a copy and keep the instruction sheet intact.

I could see a 20 lb. paper mount used in small tubes. A Tri-Fold is bulky and might block the ejection of the chute or streamer. You want the finished Tri-Fold mount to be flat and tight against the inside wall of the tube.

I'd rather see a thicker card stock used in larger models, BT-55 and above.

I drew up a sheet of different size Tri-Fold Shock Cord mounts you can print on 65 lb. card stock.

Patreon members can send an email to

oddlrockets@bellsouth.net and request the Tri-Fold Shock Cord Mount PDF

Friday, November 29, 2019

Lawn Dart Rocketry SLAT/S Build, Part 5, Tunnel and Fairing End Shaping

The ends of the tunnel are rounded off.

On the left the sides of the tunnel are rounded with a sanding block.

Draw a pencil line around the end to show the shaping depth.

Carve off some of the excess.

Finish rounding above the pencil line with 220 grit, followed by 400.

The fairings are taped off where the edge of the taper starts.

Draw a pencil line at the first layer to sand to.

The ends are sanded down the the first layer of the laminate.

The tape is removed. and the fairings are ready for CWF filler.

Here's a test fit of the fins in the fairing slots.

Thursday, November 28, 2019

I Wish They Didn't Do That - Part 3, Tape Disks

Some smaller vendors supply parachute kits you assemble.

If you can tear a tape disk before making of the parachute - the tape disk will tear under the stress of the ejection charge.

If it tears, it is made of paper.

TIP: Don't apply the disk using your fingers. The oil or dirt on your fingertips can make the disk less sticky.

TIP: Replace paper disks with plastic Avery Reinforcement Disks. Be sure the package says "Permanent".

This is the 1,000 quantity package, #5720.

200 quantity packs are also available, #5729

If you can tear a tape disk before making of the parachute - the tape disk will tear under the stress of the ejection charge.

If it tears, it is made of paper.

TIP: Don't apply the disk using your fingers. The oil or dirt on your fingertips can make the disk less sticky.

TIP: Replace paper disks with plastic Avery Reinforcement Disks. Be sure the package says "Permanent".

This is the 1,000 quantity package, #5720.

200 quantity packs are also available, #5729

Lawn Dart Rocketry SLAT/S Build, Part 4, Conduit Tunnel Shaping

While the balsa fairings dry, I worked on the Conduit Tunnel.

I don't have any half rounds, we'll carve one from a full dowel.

Draw a center line down both (opposite) sides of the dowel.

Carve off the back half of the dowel.

Notice on the right, I didn't carve all the way to the half center lines.

By the time you sand a curve into the flat back, you'll end up close to that center line.

On the left is the dowel before shaping the underside. You can see gaps on the side where it should fit the body tube curve.

On the right is the dowel after shaping the flat underside.

You could wrap sandpaper around the body tube but chances are the concave curve arc would be too shallow leaving a gap.

TIP: When shaping a part to fit a body tube, use a tube (or engine casing) that is smaller than the tube it has to fit on. You'll usually sand the inside curve wider than you intend to. Using a smaller tube or casing will give you a tighter fitting part.

Wednesday, November 27, 2019

Launch! Soccer Field, November 26, 2019

It was cold with no winds, off to an early launch at the schoolyard.

My Quest VIPER was first up using a Chinese made Quest A6-4 motor. It's always good to check your controller batteries and launcher with something easy and pretty much indestructible. Ignitions seemed slow - I'll have to change out the batteries.

Altitude was a guessed 250' with rip-stop nylon kite tail recovery.

Next up was the Estes 1/100 scale LITTLE JOE II. The launch was very fast with the Estes A10-3t engine. I couldn't get a decent burst shot.

This turned out to be the best flight of the day to an estimated 225'.

I wanted to use the Semroc Sabre parasite boost glider on the Estes SUPER ALPHA. When I took the glider out of my range box, I noticed a tail fin was broken off. I glue it back on and save it for another day.

The Super Alpha had a slow demo style boost with the Estes B6-4 to 325'. Everything was good until ejection

The parachute barely made it out of the end of the body tube! The rocket fell horizontally and slow enough there was no damage.

The Semroc SAM had it's second launch with an Estes A8-3 to 250 feet.

I haven't taken recovery shots until today. The new camera seems better than I initially thought. I tied no tangle shroud lines on this one -

I wouldn't normally launch a rocket this size with a B6-4 at this small field. The old FRANKEN GOBLIN had one of the kite tail nylon streamers packed.

Altitude was good at about 425'. The wide, colorful streamer brought it back within 100' from the launcher.

Five up, five recovered with just a cracked fin on the Sabre glider. (That one wasn't even flown!)

Tuesday, November 26, 2019

Lawn Dart Rocketry SLAT/S Build, Part 3, Fins

The original kit had 1/16" thick fins, the fairings were cut from 3/32". I made my fins from 3/32" stock.

The fin root edges fit into the slots in the fairings. I cut the notches after the fin was cut out using the end of a single edge razor blade. If your blade is new you should be able to simple press the blade down and through the balsa.

Here's how the larger, upper fin will fit into the slot. The right side of the picture is the forward end of the model.

I used thicker balsa so the slot had to be wider than the patterns showed.

For some reason the tab on the smaller fin was too long for the slot.

The three fairing pieces aren't glued together yet. I made the slot longer on the forward end so the back end of the fin would be even with the taper on the rear of the fairing.

Here's how the three fairing pieces are glued together. It's a little confusing so double check before using any glue.

The upcoming bevel shaping is shown at the bottom.

I used my flipped clothespin clamps to hold the assembly together while the glue dried.

The fin root edges fit into the slots in the fairings. I cut the notches after the fin was cut out using the end of a single edge razor blade. If your blade is new you should be able to simple press the blade down and through the balsa.

Here's how the larger, upper fin will fit into the slot. The right side of the picture is the forward end of the model.

I used thicker balsa so the slot had to be wider than the patterns showed.

For some reason the tab on the smaller fin was too long for the slot.

The three fairing pieces aren't glued together yet. I made the slot longer on the forward end so the back end of the fin would be even with the taper on the rear of the fairing.

Here's how the three fairing pieces are glued together. It's a little confusing so double check before using any glue.

The upcoming bevel shaping is shown at the bottom.

I used my flipped clothespin clamps to hold the assembly together while the glue dried.

I Wish They Didn't Do That - Part 2, Decals

Decals are sometimes a crap shoot! You never know how that sheet is going to transfer until you soak that first decal.

A suggestion for the manufacturers -

On that decal sheet, add one or two small duplicate decals and mark them "EXTRA" -Something to test the soak times and how well they transfer. With a practice decal you won't ruin the first transfer. If the decal breaks up in the soak water or folds over onto itself, you'll know it needs a coat of clear acrylic to save the remaining decals.

The decal sheet shown on the left has quite a bit of clear space where some small extras could fit. You could also practice using the "DKV-66" part designation at the upper right. But, many times decal sheets only have what is shown on the face card picture.

EDIT: From a comment from Naoto - Sometimes a "make do" practice decal (mentioned above as the "DKV-66" area) won't have a clear coating. When I was a kid building plastic models, every decal had a separate bordered clear coat. Now most decals sheets have an overall clear coat. Hold the decal up to a bright light to see if your practice decal has a clear coat - It should be shiny.

A suggestion for the manufacturers -

On that decal sheet, add one or two small duplicate decals and mark them "EXTRA" -Something to test the soak times and how well they transfer. With a practice decal you won't ruin the first transfer. If the decal breaks up in the soak water or folds over onto itself, you'll know it needs a coat of clear acrylic to save the remaining decals.

The decal sheet shown on the left has quite a bit of clear space where some small extras could fit. You could also practice using the "DKV-66" part designation at the upper right. But, many times decal sheets only have what is shown on the face card picture.

EDIT: From a comment from Naoto - Sometimes a "make do" practice decal (mentioned above as the "DKV-66" area) won't have a clear coating. When I was a kid building plastic models, every decal had a separate bordered clear coat. Now most decals sheets have an overall clear coat. Hold the decal up to a bright light to see if your practice decal has a clear coat - It should be shiny.

Monday, November 25, 2019

Lawn Dart Rocketry SLAT/S Build, Part 2, Fin Fairings

Here's a cross section drawing of the model. The instructions call the assemblies "Fin Pods".

The fin fairings are interesting, made up of a three piece laminate.

There are three pieces on each side so cut out six in total. In the top picture is all six stacked up for uniform sanding.

Two of the three pieces on each side are cut for the fin tab fitting.

The sides of the middle notch is easily cut out using a single edge razor blade. Cut down to the long , straight bottom of the notch.

The longer center line is cut with a knife and straightedge.

The top piece notch is a bit trickier. This is one of the few times I'll use an X-Acto #11 blade instead of the break-off blade knife.

Cut the short sides first, then the longer middle cuts.

Rescue & Restore!

While not Model Rocketry related, I found these videos very interesting. Some people buy older, finished rockets on Ebay and restore them to flight.

This video is from a group called "Rescue & Restore" where old metal Tonka style toys are brought back to better than new condition.

To see the video: CLICK HERE

I've never watched the curing of a powder coat finish before. It goes from a flat finish to smooth gloss in an oven.

In the picture above, rivets are set using a clamp. Notice how the stick on decals are applied, using the tip of a knife blade - where have you heard that before?

The video finish is worth waiting for - be sure to watch through to the end.

This video is from a group called "Rescue & Restore" where old metal Tonka style toys are brought back to better than new condition.

To see the video: CLICK HERE

I've never watched the curing of a powder coat finish before. It goes from a flat finish to smooth gloss in an oven.

In the picture above, rivets are set using a clamp. Notice how the stick on decals are applied, using the tip of a knife blade - where have you heard that before?

The video finish is worth waiting for - be sure to watch through to the end.

Sunday, November 24, 2019

Lawn Dart Rocketry SLAT/S Build, Part 1, Parts

The last page of the online instructions is a detailed parts list.

The body tubes are "ST" or Centuri style tubing. I'll be using heavy walled BT-50H and my Odd'l Rockets heavy wall BT-20H for the engine mount.

The OOP kit used a balsa nose cone with four washer weights to move the C/G forward. I'm using an Apogee plastic nose cone that has plenty of room for clay weight if needed. My main body tube will be 1 1/2" longer to help with stability.

The shorter white tube is another length of BT-50H for the bottom intake.

The long dowel will end up as the conduit tunnel. The short dowel was to be used for the front of the intake. I ended up using a split nose cone like on the Odd'l F-104 kit intakes.

All the 3/32" thick balsa are scraps, leftover pieces from laser cut sheets from kits. The picture on the left are the printed paper templates. The three piece laminate fairing is on the top, notice the cutouts for the fin tabs. The 1/16" thick fins are on the bottom. All the balsa pieces (fins and fairings) will be 3/32" thick.

I Wish They Didn't Do That - Part 1, Printed Shrouds

This is not a slam directed toward any kit manufacturer -

Occasionally I hear from a builder about one of my Odd'l Rockets kits. They offer a suggestion about how something could be improved. Sometimes that suggestion is implemented to improve the quality of a kit or accessory.

SUGGESTION: I wish vendors wouldn't print the company, kit name or copy on a card stock shroud. A novice builder would roll the shroud with that black ink image on the outside of the shroud.

The ink could bleed through and be visible after the model is painted, especially if the final color is white.

There's a lot of border area on the sheet. The rocket name, art and the wording "Shroud Pattern" could be placed outside of the used card stock area.

Occasionally I hear from a builder about one of my Odd'l Rockets kits. They offer a suggestion about how something could be improved. Sometimes that suggestion is implemented to improve the quality of a kit or accessory.

SUGGESTION: I wish vendors wouldn't print the company, kit name or copy on a card stock shroud. A novice builder would roll the shroud with that black ink image on the outside of the shroud.

The ink could bleed through and be visible after the model is painted, especially if the final color is white.

There's a lot of border area on the sheet. The rocket name, art and the wording "Shroud Pattern" could be placed outside of the used card stock area.

Saturday, November 23, 2019

Lawn Dart Rocketry SLAT/S Background

I found this kit listed on Ebay:

I won't be bidding on this one, I can pretty much clone it from spare parts.

The instructions and full size templates are available at oldrocketplans.com: CLICK HERE

I searched some other websites and found a build by Nick Esselman on rocketreviews.com: CLICK HERE

I'm not very familiar with Seattle Rocket Works. Apparently the design rights were transferred to Lawn Dart Rocketry.

This is an interesting design, like a strange offspring from the Jayhawk family.

The back end has built up fairings around the fins. On the underside is a ramjet intake. Along the top is a half round conduit tunnel.

There is lots of pieces to form, the details are out of the ordinary.

The upcoming build won't be a direct clone, I'm making a few changes while keeping the feel of the original kit.

I won't be bidding on this one, I can pretty much clone it from spare parts.

The instructions and full size templates are available at oldrocketplans.com: CLICK HERE

I searched some other websites and found a build by Nick Esselman on rocketreviews.com: CLICK HERE

I'm not very familiar with Seattle Rocket Works. Apparently the design rights were transferred to Lawn Dart Rocketry.

This is an interesting design, like a strange offspring from the Jayhawk family.

The back end has built up fairings around the fins. On the underside is a ramjet intake. Along the top is a half round conduit tunnel.

There is lots of pieces to form, the details are out of the ordinary.

The upcoming build won't be a direct clone, I'm making a few changes while keeping the feel of the original kit.

Friday, November 22, 2019

In 1969, Airbrushing - Getting That Catalog Finish!

Here's a page from the Estes catalog from 1969. This was the the first model rocket catalog I saw when I peeked over the shoulder of the classmate sitting in front of me. He was supposed to be studying, but had the Estes catalog open inside his textbook.

That first glimpse changed things for me. No more static, display plastic models - These things flew!

Kits followed, my first being the Centuri Javelin. I found it in a small comic book ad.

Like the rest of us, I studied and re-read the catalogs. I tried to get my models to look like those in the catalog pages - smooth and shiny. For the first few years I didn't have much luck.

In 1973 I got a job at a local print shop as a Graphic Artist intern. I was introduced to airbrushes. Then it clicked - this was how they got their catalog model pictures so smooth! They touched up any rough finish with an airbrush.

Except for a few full color pages in the catalog, most rocket pictures were black and white and airbrushed. By today's standards this 1969 airbrushing wasn't very well done. Still, these doctored images sold a lot of kits!

The Starlight is a good example. If you've ever built one you know it is nearly impossible to fill the balsa grain under and around the rings. There are four fins and four ribs spaced too close to fillet, fill and sand. Four coats of sanding sealer and sanding between coats on that design? No thanks.

Jump ahead three years -

Check out the subtle fin tip contrails in the 1972 Centuri catalog. This is a great example of effective airbrushing. I always thought this was the best model rocket catalog ever produced. I remember taking it into the print shop and showing it to the head artist.

By now the catalog models were actually pictures of real, finished models, without much touch up.

TRIVIA: That Vulcan is a pre-production model, the graphics did change by the time the kit was actually produced.

Estes Space Corps Corvette Class, #7281 Build, Finished

Thursday, November 21, 2019

Estes Space Corps Corvette Class, #7281 Build, Part 8, Decals

Here's the upper wrap decal. Look close and you can see the center pencil line from the last post.

On the back side there is an overlap.

TIP: The paper towel is stuffed in the top of the body tube to keep the shock cord from falling out and getting in the way.

The fin decals are large and detailed.

There are three sets of two different decals - meaning the patterns do repeat.

I set the duplicate decals as shown on facing fins.

Mentioned earlier, the decals are very thin and prone to folding and sticking to itself.

On the left is the top of the vertical SPACE CORPS decal. Keep a border around the edges, don't cut into the inside corners.

TIP: When placing a cockpit decal over a curved surface nose cone, you probably should cut out the inside. It'll roll and conform easier over the tapered cone.

Wednesday, November 20, 2019

Tools - The Essentials, A Decent Sanding Block, Part 2

Here's the bottom plate.

I wish there wasn't holes in the bottom, these didn't seem to effect the tools use. The sandpaper is stiff enough that it didn't "dimple" into the holes.

The pressure clamps hold sandpaper fairly well, not as good as the older wing nut clamp.

But - Using the sticky back sandpaper from Home Depot, the sanding block works very well. It easily peels off!

Without the open ends of the sandpaper wrapped around the edges and under the top clamp, the red handle top wiggles a slight bit.

I took two strips of the sticky backed sandpaper and set them under the clamp top. The top is snapped in place and the handle doesn't move.

If I didn't have the OOP Great Planes blocks, this would be a good second choice. I would probably have two - One with the sticky backed 220 grit sandpaper and a second block with 400 grit.

Subscribe to:

Posts (Atom)