Wednesday, June 30, 2021

Quest Gamma Ray Build, Finished

Tuesday, June 29, 2021

LAUNCH! Schoolyard Soccer Field, June 28, 2021

Monday, June 28, 2021

Quest Gamma Ray Build, Stickers

Sunday, June 27, 2021

School Glues?

Here's what I found online - so it's got to be true.

"School glue is a nontoxic and washable adhesive made for the classroom. It comes from a line of glues made with PVA or poly vinyl acetate. White glue is water-based and so is school glue. Because they are water-based, both white glue and school glue are not used for bonding heavy materials, metals or anything less porous than wood.

Made For Kids

White glue is used for bonding things like paper, cardboard and wood. It dries fast and can even bond fabrics. For use in schools, however, the glue needed to be more forgiving. School glue is washable and of a lighter strength than other glues in the white glue family to protect the desktops, clothing and other materials that would unintentionally come in contact with the glue. School glue is also nontoxic, although it does maintain a slight smell that the Elmer’s Glue company calls “acetic.”

Bonding Materials

School glue is strong enough to bond paper and lightweight paper products including cardboard. It can handle the projects that students create in the classroom. Macaroni pictures and string art are a few of those projects. However, school glue cannot handle the projects that many other white glues can. Bonding wood pieces, ceramics, and even glass are materials that would not hold a bond using school glue, but do respond to white glue.

Physical Traits

White glue is white in color and so is school glue. They are both thick, viscous liquids. School glue is thinner, more runny than white glue. School glue also dries white, while many of the white glues dry clear. Both glues dry quickly, but school glue may not bond heavier materials like wood, no matter how much pressure is applied.

Other Considerations

Some wood glues are white and not PVA-based. However, all school glue has the PVA to allow for the thin consistency, according to the Scale Model Guide. Both glues are easy to remove from the skin when dry. They peel right off. the glues also wash off with soap and water. Because white glue is much thicker, it does give some resistance when washing off."

References:

Elmers, “Material Safety Data Sheet,” Elmer’s Glue All.

Elmer’s, “Material Safety Data Sheet,” Elmer’s Washable School Glue.

Scale Model Guide, “All About Glue.”

I thought it was interesting that School Glues dry white, many White Glues dry clear.

Saturday, June 26, 2021

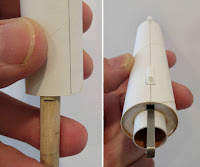

Stickers On The Quest Cobalt

The picture above shows a finished Quest Cobalt build. It's a short, 4 fin, nose cone model with streamer recovery.

Friday, June 25, 2021

Estes Indicator #7244 Build, Finished

Even with my painting error and decal problems, the model looks good.

It's size reminds me of the Estes kits from the late 1960s.