I had some concerns and was a little confused when building the A.S.P. MMX Jayhawk.

A quick email to Andy at A.S.P. got some easy answers.

I was sent a pre-production kit. Before the kit went into full production, corrections were made in the templates and decals.

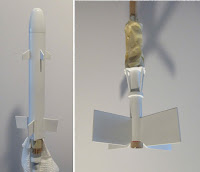

Note the "root edges" designation and arrows.

Here's the corrected version, now in the kits.

The illustration is flipped and the "root edges" are now clear.

This decal wrap in my kit had one of the Stars and Bars flipped. When wrapped around the body, one star ended up upside down. I simply cut off the stars and bars and turned it over.

The kits now have Stars and Bars in the correct orientation.

I've produced a few kits and can certainly understand how this happens.

On my Odd'l Rockets F-104 Starfighter kit I left off a measurement. On the first run of kits, the instructions said to glue a cut tube XXXX" from the back end of the model. The XXXX" was a pre-production place holder for the final measurement.

Measurements, parts, instructions and templates can change as you go through prototypes and test flights. Producing kits (especially the instructions) takes more time than most modelers realize.