While the model is constructed using medium CA glue -

I'd recommend using epoxy for gluing in the coupler.

If you don't have experience using two-part Epoxy glue:

1. Wear gloves, you might be allergic or over time develop a epoxy skin reaction.

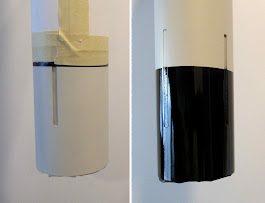

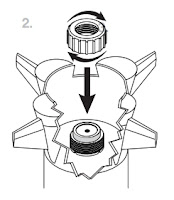

2. Parts (like couplers) glued using epoxy can slide before it sets up. Slide the coupler in up to the 3" pencil mark, but check back every few minutes while it dries. If drying vertically, the coupler/tube assembly could slide and lock up in the wrong position.

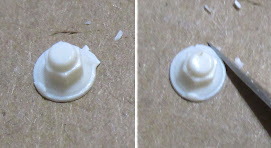

Epoxy was mixed and applied inside the upper tube so any excess would stay inside and not be squeezed out onto the coupler.

The coupler is slid in and turned while sliding it up to the 3" pencil line.

Turning the coupler spreads the glue evenly and makes a smooth fillet bead at the top inside edge of the coupler.