I'm going to enter the Altitude Payload event at NARAM this August. It's been a long time since that last contest, things have changed!

I don't really know what I'm doing so I'm taking the easy way out by building the Payload Altitude Rocket from Apogee. This design is interesting, it holds an altimeter and the 1 oz. payload unit in the payload section.

(Picture from the Apogee website.)

The old NAR 1 oz. payload was a cylinder of lead! This illustration is from the 1975 Estes catalog.

Can't use lead anymore! I don't think I suffered any side effects from handling the lead payload, I didn't keep it in my mouth very long.

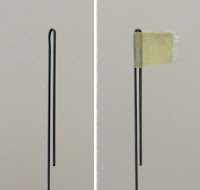

Now a NAR payload is a capped BT-20 sized tube with 1 oz. of sand inside.

Years ago, the NAR altitude competitions used Theodolites to visually track and compute rocket altitudes. The picture on the left is the Centuri Sky-Trak. To see it:

CLICK HERE

When the ejection charge went off, the angle on the protractor was recorded. After some elementary Trigonometry, you have an altitude reading. Visual tracking was iffy. You could add some colored chalk so the tracker was more likely to see the ejection.

That powdered chalk got everywhere!

At one time I did have an Estes Altiscope but don't remember getting satisfactory results from it. The Altiscope was primarily wood. A clear tube held some oil in it. You tracked the rocket by eye. At apogee a metal rod was pressed down, "locking" the oil flow reading against a paper wrap protractor. To see it:

CLICK HERE Check out the screw eye "sights" along the top.

Today you use a NAR approved electronic altimeter. I recently bought a Perfectflight Firefly.

It's amazing how small and light the unit is. It fits into a BT-20 tube! It reads the barometric pressure to give the altitude. Count the flashes and you have the peak of flight!