As I reported on the NAR Facebook page last Sunday, I regret to have to inform you that a fatal on-field rocketry accident occurred in California last Saturday. I want to bring you up to speed on the status of our investigation.

When I made the first announcement, there were few details available. We have since been working to understand what happened, so that we may all learn from it and prevent it from happening again. Our Association has no standing in the matter except as concerned and experienced enthusiasts, but I've been in contact with law enforcement and witnesses and have a preliminary set of facts to share.

First, to the best of our knowledge, no NAR or TRA members were involved in this incident, certainly not directly involved. No kids were involved, except, unfortunately, as witnesses.

The deceased, Mike Bentley, a very experienced adult Scout leader, was at an annual BSA Council-sponsored rocketry and camping event for multiple scout troops called Rocket Rave, which has been conducted for at least several years. During the weekend, scouts complete tasks required for their Space Exploration merit badge, which requires two model rocket launches. During the launches, it has also been common for adults to launch their own, larger rockets.

Around noon on Saturday, Mike engaged in a drag race with a second adult. Winds were likely within limits, safe distances were at least close to being met, and both rockets probably met the weight and power limits defined by the NAR Model Rocket Safety Code. The drag race was conducted from a dedicated area, to one side of the primary launch pads for the scouts to use to fly their conventional A through C powered model rockets, and about two dozen people were in the immediate vicinity.

Mike's rocket was powered by a small APCP motor; the other rocket was powered by at least one, and possibly more, black powder motors. Both rockets launched; while Mike was watching his rocket, the other rocket arced over and came down ballistically, striking him in the face and causing severe injuries. Despite the best efforts of scouts, law enforcement, and medical professionals both at the scene and afterwards, his injuries were ultimately fatal.

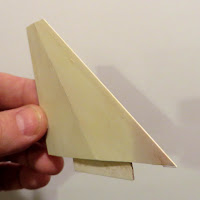

We know that the rocket that struck Mike was about four feet long and four inches in diameter. It had a cardboard body tube and a plastic nose cone. We don't know much else for sure. It is possible that the rocket was designed to fly on a cluster of motors, but at least one picture of the flight does not clearly show more than one motor firing. No parachute was deployed; none was seen at the accident site. At least one report indicates the rocket was damaged prior to flight. We don't know what motor(s) were used and whether they all ignited and functioned as designed. We don't know if applicable local laws were fully observed.

I do know that the investigating law enforcement authority is not pursuing a criminal investigation at this time. The lack of an investigation will likely leave questions unanswered for some time. We don't know if the rocket would have been allowed to fly at a NAR launch; we can't definitively say whether the NAR safety code was observed or not. We will continue to gather information to the best of our ability, and we'll pass on significant new findings to you.

Where does this leave us? We know that rocketry remains orders of magnitude more safe than any other outdoor activity we can name, provided the safety codes are followed. But it is not without risks; the safety code is our primary means of mitigating those risks.

Everything in the safety codes is there for a reason, and I urge you to continue to observe-and when prudent, exceed-their recommendations every time you fly.

- Do preflight inspections of every rocket. Be especially careful with complex rockets. Pay special attention to the recovery system.

- Tilt your launch guides away from the crowds: Plan to have good flights, but also plan for bad flights to end in safe places.

- Add to the safe distance standards when lots of observers are present.

- Make sure launch controllers and ignition methods are appropriate for the motor(s) being used.

- Have a spotter for every rocket in a drag race, near enough to the RSO to be able to get a warning out if necessary.

- Have people point at malfunctioning rockets if they see them.

- Make sure the crowd can hear the RSO.

- Confirm the stability of untested designs.

- If rockets are flying over spectators, stop and fix the problem.

- Offer to help people and groups who are just starting down the path that we have trod. Set a safe, positive, and helpful example.

Please consider contributing to Mike's memorial fund through his gofundme site.

I'll continue to keep you informed, so that we can learn what we can from this unfortunate accident, and be safer because of it.

|