I tried the Future Acrylic clear coating a few times before.

Many rave about the results on forum posts. I was frustrated not able to get the finish others have written about.

I'm able to get a good gloss on a rocket by spraying a heavier final color coat.

You've got go be careful though, a little too heavy and runs can start.

Usually I'll do two light color coats and then the heavier final coat.

But after that - my decals were never protected. Never thinking a clear coat was necessary, the decals rarely lift or come off.

Still, I wanted to give clear coating a try.

I tried applying the Future with a spray bottle. After spraying the first time, there was bubbles and runs.

I was told to leave it alone and the bubbles would disappear when it dried. A paper towel was used to pick up the drips.

I probably tried too hard to get it smooth while it was still wet.

The Future dries quickly and my "dabbling" left an uneven surface on the ends and edges. I could see some glossy, smooth surfaces on the model though.

A foam brush was tried next with the same results.

On the Rocketry Forum, Jim Fustini posted about Americana spray acrylic:

"It is not exactly like Future, but it is an Acrylic clear coat. It gives you that "wet look" and it dries to a harder finish than Future. I bought mine at Michael's."

I figured I'd have better control with a spray clear acrylic.

Sure, Krylon has made a gloss spray acrylic for years but I've heard stories of the decals crinkling up when it is applied over them.

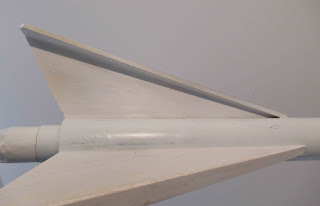

The Americana Acrylic was sprayed onto the recently refinished Red Max.

It was sprayed lightly first to test for any reaction on the decals. There was no reaction.

I finished up with a heavy spray of the clear like I would normally do on a final color coat.

It didn't drip or run!I ended up with the finish surface I'd been looking for -

A smooth, clear wet look and protection for the decals.The picture doesn't really show how shiny the surface is.

Many thanks to Mr. Fustini for this tip!P.S. Don't blame me if this doesn't work for you, "crazes" the decals or ruins your model's finish. Test on scrap material before applying to your model. I'm just passing this on as a new clear coat product.