The streamer is tied onto the shock cord, 2 1/2" from the top edge of the body tube.

This is some 400 grit sanding, taking down the rough spots and small side ridges left from the Titebond Molding and Trim Glue (or No Run - No Drip, whatever they call it this week) fillets.

The rocket got another shot of gloss white. There was still a bit of sanding. I sanded too far and some wood showed through on the dowels. I didn't want to shoot white gloss again, that's more weight.

TIP: I did some paint rolling with Q-Tip "brushes".

A small baggie is pressed into a mixing cup. Spray gloss white into the bag until a puddle of paint is in the bottom. Dip the Q-Tip into the paint.

Wipe off some paint on a paper towel. There will be more paint on the Q-Tip than you'll need.

ROLL, don't brush the Q-Tip over the area.

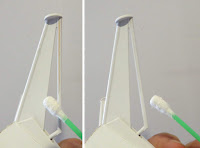

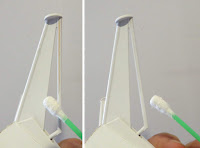

On the left you can see the wood peeking through the paint on the dowel legs. On the right the touch-up paint has been applied.

The Rustoleum rolled on like this blends pretty well. You can use this on dowels and rounded leading

edges of fins - not on large flat areas.

The rocket got another shot of gloss white. There was still a bit of sanding. I sanded too far and some wood showed through on the dowels. I didn't want to shoot white gloss again, that's more weight.

The rocket got another shot of gloss white. There was still a bit of sanding. I sanded too far and some wood showed through on the dowels. I didn't want to shoot white gloss again, that's more weight.