With the O and R "cut" directly over the tube joint, sight down the body to make sure the orange line and type are straight. Tape down the sticker.

Use your aluminum angle to check the orange stripe is straight.

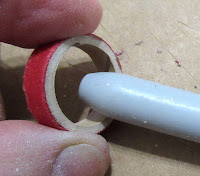

I peeled the backing on the orange strip and lightly held the vinyl. The backing was cut off up to the R.

The placement illustration says to overlap by 1/8", but I wanted to end up with a clean cut between the O and the R.

A 1/4" overlap puts the cut between the letters.

Double check the 1/4" overlay of the orange stripe joint before peeling off the backing.

The orange stripe was set over the upper stripe matching the edges.

With the ends matched up, the backing is pulled under the name. Carefully set down the name checking the straightness as you go.

Add the "C" tail sticker at the low end of the orange stripe.

GOTCHA: The illustration drawing shows the "I" even with the top of the fins. The provided sticker lengths end up with the name higher up on the model.