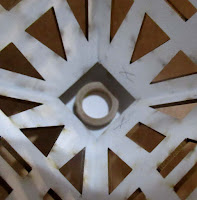

The top and bottom front plates are creased to fit and cover the open area at the tp of the rear assembly.

The embossed lines were folded over the edge of my straightedge.

The forward bend was creased sharp using a burnisher.

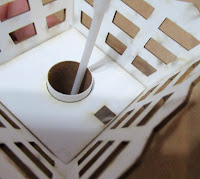

Here the model is upside down with the bottom plate facing up.

Here's how the front looks. Notice the "sandwich" of the lower plate bend, the thick central plate in the middle and the upper plate front bend.

The canopy marking guide is set to the left and the inside line traced with pencil.

Flip it over and trace the other side.

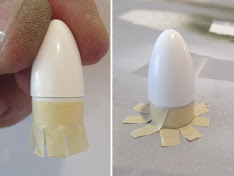

Do some canopy dry fits. The inset picture shows the canopy front where the cut out angle fits over the fold of the front plate.

You'll find the right and left side of the canopy has to open up to match the traced pencil lines.

Before gluing the canopy on, I reformed the canopy base wider than how it ended up after gluing together.

Rather than set glue on the very thin inside edges, I held the canopy on the pencil lines then applied short shallow glue fillets.

When gluing thin cardstock like this, you don't initially need much glue.