I did a tug test on the pre-made parachute shroud lines. They easily broke!

Another kit needing shroud line replacement.

A painting dowel was stuck into the engine mount and some paper towel strips stuffed into the back to keep the paint out of the engine mount.

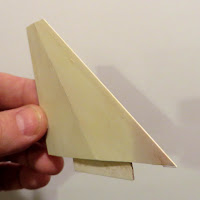

The body tube was slip over the fin can, no glue yet.

A piece of rolled copy paper was pushed into the front open tube end.

The model got the first coat of gloss white paint.

TIP: Here's one way to knock down any paint inside the lip of a launch lug. Gently turn the pencil in the launch lug end.

The sides of a sharpened pencil are a little rough and just enough to rub off any paint and re-round the lug.