Here's something I found on Pinterest: Small Spray Shelter

CLICK HERE to see it on Amazon.

It could be used for some rocket builds.

It never occurred to me to use something like this, it reminds me of a small pop-up tent.

Check out his filter mask. If you're not spraying outdoors, you'll need one of these.

My mask is not that good, maybe I should upgrade!

Monday, October 31, 2016

Semroc (Estes) Starship Excalibur Build, Part 30, Decals

TIP: Never use water slide decals unless the model paint is totally dry. If the paint is even slightly tacky you won't be able to slide the decal into the final position.

On the left: Wet the surface by rubbing some water at the decal location. Inset picture: After the decal is positioned, use a damp Q-tip to roll out any air bubbles and to press the decal into the corners.

Work the air bubbles out from the center to the edges.

The front end of the long orange bands overlap the nose cone joint.

Place the decals with the nose cone on. After the decal dries cut through the joint with a razor blade.

The crew module windows are long and narrow.

It's easier to place a thin decal by doing it in two pieces.

The inset picture shows the front windows. I cut them close for an easier fit around the nose cone contour.

On the left: Wet the surface by rubbing some water at the decal location. Inset picture: After the decal is positioned, use a damp Q-tip to roll out any air bubbles and to press the decal into the corners.

Work the air bubbles out from the center to the edges.

The front end of the long orange bands overlap the nose cone joint.

Place the decals with the nose cone on. After the decal dries cut through the joint with a razor blade.

The crew module windows are long and narrow.

It's easier to place a thin decal by doing it in two pieces.

The inset picture shows the front windows. I cut them close for an easier fit around the nose cone contour.

Sunday, October 30, 2016

Semroc (Estes) Starship Excalibur Build, Part 29, Decals

Here's the new name decal, printed at home.

Choice #4 seemed to be the favorite. It certainly looks better than the original Dom Casual font.

TIP: Never soak a large kit decal first.

I cut off the catalog number corner to check on soak times and how it slides off the backing paper.

If this test decal bleeds or tears it might need an additional clear coat.

If you don't have one, get some long tweezers. It comes in handy if you have to fish the decal out of the soak water.

Dip the decal all the way into the water first, then float the decal on the top.

I usually start with a 30 second soak then see if it slides on the backing paper. If not, I'll soak it some more.

Estes Alien Invader Decal Fix

I finally set the decals down on the second Alien Invader. I think I got it right this time.

The white decal on the tube sides won't fit the way the face card shows it. With the dowel in the location specified in the instructions, this decal is too tall. I turned it on its side.

This time the three stripe decal was set up on the main body tube and tucked into the root edge of the fin.

The smaller alien eagle decal was correctly set to the forward right side of the body tube front. This decal isn't shown in the reissue kit instructions. You've got to look up the old kit online instructions to figure it out.

The larger alien eagle went underneath the model on the right wing.

Done!

I may hit the lower half with a dullcoat to make it interesting. The dullcoat will hide some of the areas that aren't as clean as I would like.

Saturday, October 29, 2016

Vern Estes Signed Alpha Auction

The finishes Estes ALPHA, Signed by Vern Estes

Ebay Auction finishes up tonight around 10:00 p.m., EST

Stop by, make a bid and support the blog!

Semroc (Estes) Starship Excalibur Build, Part 28, White Paint

After all the adventures with spray paint I decided to try something new.

My can of Rusto 2X gloss white was about 1/3 full and the nozzle probably not clear. Rather than risk it, I grabbed a new can.

TIP: Before spraying directly on the model I made some passes on some scrap cardboard. Good thing - some rough "cottage cheese" sprayed out after the initial first pass.

I've written about this before, Rusto 2X can be a great paint most of the time. You just have to take some precautions.

Shake, then shake some more.

Some pigment might be in the interior feed straw. If the paint is new or has been sitting on the shelf you might want to clear whatever might be settled inside.

This time I got an even coat with a pretty good gloss.

This is a tough one to spray, too many inside areas that can get dulled with over spray.

And the front end -

After it all dries the decals will be applied.

And yes, I did print a new name decal.

Font #4 got the most votes.

My can of Rusto 2X gloss white was about 1/3 full and the nozzle probably not clear. Rather than risk it, I grabbed a new can.

TIP: Before spraying directly on the model I made some passes on some scrap cardboard. Good thing - some rough "cottage cheese" sprayed out after the initial first pass.

I've written about this before, Rusto 2X can be a great paint most of the time. You just have to take some precautions.

Shake, then shake some more.

Some pigment might be in the interior feed straw. If the paint is new or has been sitting on the shelf you might want to clear whatever might be settled inside.

This time I got an even coat with a pretty good gloss.

This is a tough one to spray, too many inside areas that can get dulled with over spray.

And the front end -

After it all dries the decals will be applied.

And yes, I did print a new name decal.

Font #4 got the most votes.

New Estes Packaging

I was picking up some B6-4 engines at Hobby Lobby today, using a 40% off coupon. I noticed one of the new starter sets.

On the back of the box was a small picture of the new engine packs. These look to be the two-engine packages mentioned before: CLICK HERE

There were no two engine packs at my Hobby Lobby store - yet.

Two 18mm engines per package? I've always bought engines in three and four packs. I've yet to purchase 24mm engines in the newer two packs.

I don't see these as being any more efficient or less expensive.

Friday, October 28, 2016

Finished Hi-Flier XL on Ebay

I have a finished Estes HI-FLIER XL on Ebay.

This is a clean build with a Centuri style baffle installed.

To see the specs or make a bid: CLICK HERE

Comments on Over Building

Over-building can be overkill in L.P.R.

On a Facebook post I saw a video of a builder using a steel fishing leader being slid through a replaceable (rear centering ring / straw feed) Kevlar mount. This was in a Low Power Rocket.

Why is a steel line in a replaceable mount? You might be better off slipping the steel end loop under the upper bend of the engine hook. A steel leader will never have to be checked or replaced for that matter - it won't degrade or melt.

The purpose of the replaceable Kevlar mount is to check the line after 10 flights or so and replace it if needed. You can't replace a Kevlar line that is tied inside, under the forward centering ring.

In his photo example, the top of the steel line extended a few inches beyond the top end of the body tube. That's a zipper waiting to happen.

To see how a replaceable Kevlar line works, check out the article I wrote in the Apogee Peak Of Flight. https://www.apogeerockets.com/education/downloads/Newsletter338.pdf

As far as I know, I came up with the idea back in 2013. I'd hate to see the technique used incorrectly.

Steel leaders have been used for years, Centuri pre-installed them in the engine mounts of the old Mini-Max line of kits. At the time, a Mini-Max F was considered high power. Currently, North Coast Rocketry uses a steel leader in their MPR kits.

Bulletproof rockets?

Forum posts have shown some people fiber glassing LPR body tubes and fins. There is no reason for this, unless you are practicing for a much larger, faster model.

"Papering" is one way to strengthen fins. Just don't add too much weight to the back end of your model, it might end up unstable.

Years back when a C engine was the limit everybody was more concerned with weight and a higher altitude. Now weight isn't as critical, most people fly for sport.

Estes kits now use a very stiff wood for their fins. Papering isn't really necessary for strength. Many builders paper their fins rather than fill the wood grain.

Don't misunderstand - I build my LPR models strong enough to last many flights, but I don't over build. I use epoxy when needed, I paper fins on occasion. But, that's about it.

On a Facebook post I saw a video of a builder using a steel fishing leader being slid through a replaceable (rear centering ring / straw feed) Kevlar mount. This was in a Low Power Rocket.

Why is a steel line in a replaceable mount? You might be better off slipping the steel end loop under the upper bend of the engine hook. A steel leader will never have to be checked or replaced for that matter - it won't degrade or melt.

The purpose of the replaceable Kevlar mount is to check the line after 10 flights or so and replace it if needed. You can't replace a Kevlar line that is tied inside, under the forward centering ring.

In his photo example, the top of the steel line extended a few inches beyond the top end of the body tube. That's a zipper waiting to happen.

To see how a replaceable Kevlar line works, check out the article I wrote in the Apogee Peak Of Flight. https://www.apogeerockets.com/education/downloads/Newsletter338.pdf

As far as I know, I came up with the idea back in 2013. I'd hate to see the technique used incorrectly.

Steel leaders have been used for years, Centuri pre-installed them in the engine mounts of the old Mini-Max line of kits. At the time, a Mini-Max F was considered high power. Currently, North Coast Rocketry uses a steel leader in their MPR kits.

Bulletproof rockets?

Forum posts have shown some people fiber glassing LPR body tubes and fins. There is no reason for this, unless you are practicing for a much larger, faster model.

"Papering" is one way to strengthen fins. Just don't add too much weight to the back end of your model, it might end up unstable.

Years back when a C engine was the limit everybody was more concerned with weight and a higher altitude. Now weight isn't as critical, most people fly for sport.

Estes kits now use a very stiff wood for their fins. Papering isn't really necessary for strength. Many builders paper their fins rather than fill the wood grain.

Don't misunderstand - I build my LPR models strong enough to last many flights, but I don't over build. I use epoxy when needed, I paper fins on occasion. But, that's about it.

Thursday, October 27, 2016

Semroc (Estes) Starship Excalibur Build, Part 27, Ah Crap! - Fix

Small bits of white glue were pushed into and under the edges of the slot.

The excess on the outside was wiped off. After cutting, the loose card stock fibers were pressed down and into the glue with a small tweezers.

The sides of the slot were also formed and squared up using the sides of the tweezers before the glue dried.

Here's the slot after enlarging and cleaning up.

I was concerned but it actually came out very well.

The excess on the outside was wiped off. After cutting, the loose card stock fibers were pressed down and into the glue with a small tweezers.

The sides of the slot were also formed and squared up using the sides of the tweezers before the glue dried.

Here's the slot after enlarging and cleaning up.

I was concerned but it actually came out very well.

Didn't Win! on Ebay

Here's one I didn't win on Ebay - a sealed MPC Starter Set.

I already have an old, beaten up MPC launcher and controller. My launcher is missing pieces, the wind direction rod and original blast deflector aren't there. The plastic is discolored and feels brittle.

This set is interesting though. A Nike Smoke rocket has been substituted and the engines are probably still in there.

Another reason I wanted it - the ceramic blast deflector. I sell MPC sized ceramic deflectors at Odd'l Rockets. My original MPC deflector was broken when new molds were made!

I went as high as $61.00 before shipping. It sold for $86.00, too high for me.

The same guy has outbid me before. I'm not a rocket collector, I have some things but not as much as others do. This set would have been a keeper.

One day - I will have a Vashon Valkyrie 2, un-assembled in the long box!

Wednesday, October 26, 2016

Semroc (Estes) Starship Excalibur Build, Part 26, Ah Crap!

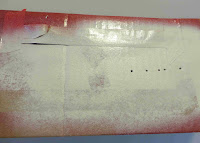

Right now I'm spraying gloss white and sanding between coats.

I went to carefully remove the painting wand (a dowel and an engine casing) I didn't want to put any stress on the tail shroud.

I slipped and the engine hook notch tore!

I had already made the notch longer than the shroud pattern showed. As it turns out, it needed to be even deeper.

I grabbed a new razor blade and first cut the corners of the end of the notch, to the left in the picture. Then the sides were cut from the left to the right side.

There was still some paper fibers on the inside of the shroud. I'll clean those up and strengthen the shroud edges in the next post.

Randy Gilbert's Nike Smoke Fins

From the NAR Facebook page, Randy Gilbert responded to a post on the Estes Nike Smoke -

"It is a great kit, but the fins can be difficult to sand to shape. There are other ways to mimic the appearance of the scale fins. In the method I show below, I glued a piece of cardstock to each side of the fin so it has the appearance of the scale fin."

This is a great work around for the time consuming Nike Smoke fin shaping. It gives the impression that the fins were tapered!

"It is a great kit, but the fins can be difficult to sand to shape. There are other ways to mimic the appearance of the scale fins. In the method I show below, I glued a piece of cardstock to each side of the fin so it has the appearance of the scale fin."

This is a great work around for the time consuming Nike Smoke fin shaping. It gives the impression that the fins were tapered!

Tuesday, October 25, 2016

Semroc (Estes) Starship Excalibur Build, Part 25, White Coats, More Sanding

You know how frustrating it is.

You think your surfaces are smooth and your fillets well rounded. The grey primer coats show things and you end up with more sanding.

Now the white coats come. I thought I'd be finished with this one by now!

The more details, the more finishing problems.

There are still some areas that will need smooth sanding.

This build has slowed me up! I usually do blog posts in draft form two weeks in advance. I'm falling behind on this one!

Old MRN Cover with Starship Excalibur

In a recent comment, Naoto Kimura found a Starship Excalibur variant on an old Model Rocket News cover from August 1968.

I have seen this cover before but never associated it with the Excalibur.

That is definitely the Starship Excalibur with three added SRBs.

No, I'm not going to add this to the build.

Monday, October 24, 2016

Signed Estes Alpha on Ebay

A finished Estes ALPHA is for sale on EBAY.

This one is special, it has Vern Estes signature on it.

I know you're thinking - Why would I sell it?

I have Vern Estes signature on some correspondence when he worked at Estes. Rather than have this rocket end up as a shelf queen, I'd rather it go to someone else who'd appreciate it.

The Alpha is in the classic 1971 catalog and face card paint scheme.

For more information: CLICK HERE

Semroc (Estes) Starship Excalibur Build, Part 24, Dry Sand & Nose Weight

Some 400 grit was wrapped around a Q-tip for cushioned sanding in all the fillets.

There is a LOT of fillets and joints to be sanded.

A washer weight goes underneath the screw eye. I would think with all the fin area this one would be stable without the nose weight.

Be sure you have centered your screw eye hole before setting the washer in place.

The instructions don't mention it, but add some glue to the bottom of the washer.

Set and center the washer then follow with the screw eye. Turn the screw eye in until it butts up against the washer.

Sunday, October 23, 2016

Blog Ground Rules

This is not directed at everybody reading the blog -

Just a few who are treating it like a forum.

I used to post more often on rocketry forums. I got tired of people telling me I was doing things wrong. "That's not the way I do it" was one of the reasons this blog was started.

If the builds and tips shown here have helped out - great!

This is simply how I do it. My methods are not the only way to get a rocket built. If you disagree with my techniques, don't post a comment to tell me I'm doing it wrong.

This is what works for me. If you don't agree, you can start your own blog.

I do welcome comments - but -

If you make a comment, don't advertise or post links to another rocketry vendor.

The blog is not here to advertise products for another vendor. I'll occasionally let you know about a sale or clearance.

If you post a website address link it might be deleted. I can't promote your rockets, cosmetics or home siding. (This has happened!)

The blog is free! If you have learned something or were helped in a build,

Please consider joining Patreon. You'll then have access to all the plans, decals and downscale PDF models. RANT OVER!

Second Stage Veering Off? TIP

THIS IS BIG!

A post from Hornet Driver on The Rocketry Forum:

". . . I gotta tell ya, I've never had a multistage rocket--no matter what type it is--track straight up . They always kick over at least a little when staging and the more you stage the more the problem. I'm personally convinced that it's caused by the sudden KICK when the upper stage lights off. I've gotten away from staging for the most part since my stuff always ends up in the next county over." --- H

____________________________________________________________

My response:

I've had the same results with two-stagers.

Boost is fine but when the upper engine kicks in it'll veer off at an angle. I don't think it had anything to do with the wind.

That one inch (or less) of a coupler to guide the upper stage doesn't seem to help much.

I avoid flying staged models. I do like clusters, though.

Hans "Chris" Michielssen

Old/New NAR # 19086 SR

__________________________________________________________________________

Response from John Boren of Estes:

We've flown well over a thousand two stage models here at Estes over the past few years and I've found by having the booster fit super loose into the upper stage is the key to the upper stage not veering off course at stage separation. In fact the booster on our E2X lines of models will fall off if let go: They are that loose.

John Boren

Thanks John! So that was my problem all along?

A post from Hornet Driver on The Rocketry Forum:

". . . I gotta tell ya, I've never had a multistage rocket--no matter what type it is--track straight up . They always kick over at least a little when staging and the more you stage the more the problem. I'm personally convinced that it's caused by the sudden KICK when the upper stage lights off. I've gotten away from staging for the most part since my stuff always ends up in the next county over." --- H

____________________________________________________________

My response:

I've had the same results with two-stagers.

Boost is fine but when the upper engine kicks in it'll veer off at an angle. I don't think it had anything to do with the wind.

That one inch (or less) of a coupler to guide the upper stage doesn't seem to help much.

I avoid flying staged models. I do like clusters, though.

Hans "Chris" Michielssen

Old/New NAR # 19086 SR

__________________________________________________________________________

Response from John Boren of Estes:

We've flown well over a thousand two stage models here at Estes over the past few years and I've found by having the booster fit super loose into the upper stage is the key to the upper stage not veering off course at stage separation. In fact the booster on our E2X lines of models will fall off if let go: They are that loose.

John Boren

Thanks John! So that was my problem all along?

Up until now I've never read that a booster coupler should be "super loose".

I'm putting together a Long Tom right now. Right out of the bag, the red coupler was very tight. I've sanded it for a better slip fit, I guess I'll have to take it down even more! In the past I've tried for a slip fit on a staging coupler. Not too tight, not too loose.

This is probably why I fitted couplers this way -

Looking back at the 1970 Estes Technical Manual: CLICK HERE

"Rockets using large diameter tubes (BT-50 and BT-60) require somewhat different methods but the same principles of tight coupling and straight line separation must be followed. The recommended coupling method for large diameter tubes is illustrated in figure 4."

That same copy is used in the original Estes TR-2 on Multi-Staging. To see the Technical Reports: CLICK HERE

I'm putting together a Long Tom right now. Right out of the bag, the red coupler was very tight. I've sanded it for a better slip fit, I guess I'll have to take it down even more! In the past I've tried for a slip fit on a staging coupler. Not too tight, not too loose.

This is probably why I fitted couplers this way -

Looking back at the 1970 Estes Technical Manual: CLICK HERE

"Rockets using large diameter tubes (BT-50 and BT-60) require somewhat different methods but the same principles of tight coupling and straight line separation must be followed. The recommended coupling method for large diameter tubes is illustrated in figure 4."

That same copy is used in the original Estes TR-2 on Multi-Staging. To see the Technical Reports: CLICK HERE

Saturday, October 22, 2016

Semroc (Estes) Starship Excalibur Build, Part 23, Cleaning Up The Lugs

There was a rough edge on one side of the launch lug opening.

While the first white undercoats were not totally dry, a sharpened dowel was turned in the end, re-rounding the lug.

The front lug antenna housing needed some cleaning up. The sides weren't totally square.

The side of my knife was set against the flat opening compressing the balsa and paint.

Here's the cleaned up opening.

The picture is distorted, the antenna and square opening are centered.

Friday, October 21, 2016

More Stuff - Need More Stuff!

NO . . . Must Resist!!!

Estes has just added new bundles to the clearance sale pages: CLICK HERE

I still have some kits left from the last bundle deals. These are some great prices though.

Semroc (Estes) Starship Excalibur Build, Part 22, Fin Gluing

The fin root edges were sanded down removing most all of the grey primer filler.

The first fit required some of the inside tab to be sanded off until the fin sat flat on the crew module and BT-5 tubing slots.

Here's one of the fins after fitting.

Be sure to check the centering of the forward fin vane as shown in the inset picture.

Here's the moment every builder waits for, the finished assembly.

An impressive model.

Wednesday, October 19, 2016

Well Used Red Max on Ebay

From YORF, Frognbuff found this beauty on Ebay:

From YORF, Frognbuff found this beauty on Ebay:Vintage Estes Red Max - USED

Starting bid: $19.95

Expedited Shipping to Orlando only $25.95

"Red Max rocket. Used condition. String needs to be reattached to chute.

No engines. It measures 15" tall. Please look at pics closely."

I've heard of fix-er-upers but this is pretty ridiculous.

String needs to be reattached to the chute? That's the big concern?

I sometimes sell finished models on Ebay. This would never make the cut!

There's a broken, rotted shock cord down inside that out of round tube!

To see the Ebay listing: CLICK HERE

I might follow this auction to see if it gets a bid.

Starship Excalibur build continues tomorrow!

Master Bath Mirror Framing

I recently framed the mirror in the master bathroom.

This was one of those big mirrors, just stuck to the wall with adhesive. It was too big and a frame would warm up the room and make the mirror appear smaller. Rather than pulling it off the wall and leaving holes in the drywall to fill, (I've been through that before) I simply framed it with decorative door casing pieces.

Why is this on the blog?

Cutting, fitting, gluing, caulking and painting all came into play.

Without the experience from model building I wouldn't have the skills, problem solving or patience to tackle a project like this.

Hydra Sandhawk Ebay Auction Ending -

Bidding finishes up Wednesday night (tonight) at around 10:00 p.m.

No bids yet! This is a BT-60 based two stage model.

Stop by and support the blog: CLICK HERE

Semroc (Estes) Starship Excalibur Build, Part 21, Launch Lug Gluing

These two inline launch lugs are different. They are covered or surrounded with built-up wood and dowels.

The front "antenna" housing was built earlier. It is glued 1 3/8" from the top of the main air frame tube.

The long rear lug is centered between the split BT-5s and even with the tube end.

The rear lug gets dowels on both sides and the remaining fin vane is flipped over and glued on tip.

This should have been pictured earlier, when the long lug was first glued on.

Always line up two lugs with a launch rod section. You can tell how well the lugs are centered between the BT-5s with the rod between them.

Subscribe to:

Posts (Atom)