I realized there would be a problem with the long shroud. How can I make vent holes for the altimeter with the shroud in the way?

While I would have liked the long shroud for less drag, I needed more body tube exposed below the shroud for the vent holes.

I went back to PayloadBay.com and printed up another.

TIP: Note the glue tab is narrower at the bottom and the corner angles are steeper at the bottom (see arrows) This helps with a flatter fit at the tube joint.

I formed a clean, narrow glue line for the bottom of the shroud at tube joint. I takes very little glue to hold paper to paper joints.

No centering ring is needed for inside support. The open top of the shroud is supported by the fit against the egg capsule.

I had some Apogee Fly-Away guides for 13mm and 18mm body tubes. These weren't high enough to clear the egg capsule. Apogee sells a guide for use with the egg capsule, I just didn't see it.

I'm glad I saved all my old instruction sheets! Here's the old CMR pop-lug with standoff for egg lofting. This might be a second version of the pop-lug with the smaller lower wire hook.

There is also small segments of body tube that better hold the wire on the standoff.

The fit of the pop lug is very good with clearance for the launch rod.

Showing posts with label Pop Launch Lug. Show all posts

Showing posts with label Pop Launch Lug. Show all posts

Saturday, August 25, 2018

Tuesday, May 29, 2018

Apogee Payload Altitude Rocket Build, Part 8, Pop Launch Lug

The doubled tip of the top wire is bent to allow an easy insertion and removal in the hole in the body tube.

I'll be using the altimeter vent holes already in the upper payload tube.

This is the bent wire that friction "clips" behind two facing fins.

The initial bend is adjusted to fit each individual model and fin shape.

Both the top and bottom wires are either taped or attached with glued card stock to the top and bottom of the long launch lug.

For an easier fit of the top wire, the hole was formed so the upper end of the hole is pushed out a bit. The low end of the hole is pushed in at the same time. I used a small rat tail file to press and form the hole, I didn't file or removed any body tube wall thickness.

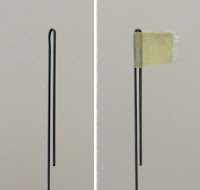

On the left is the pop lug beside the body and ready to place on the model.

On the right - The upper bend is slid in one of the altimeter holes.

The sides of the lower wide bend are set behind two facing fins.

The pop lug will stay on the rocket long enough for it to get up to stable speed. At the top of the launch rod the tape wraps stop the lug, leaving it on the rod. The rocket continues up without the drag of the launch lug.

HISTORY: As far as I know, the Pop Lug was designed by Col. Howard Kuhn of Competition Model Rockets or C.M.R. He came up with many rocketry innovations including the smart, simple Kuhn Tube Cutter. C.M.R. was the first to manufacture lightweight vacu-form nose cones and egg capsules.

Monday, May 28, 2018

Apogee Payload Altitude Rocket Build, Part 7, Pop Launch Lug

I'm going old school, I hope pop lugs are still allowed in competition! I hope to find out find out before going to NARAM.

In the comments below, let me know if they are still used in contest flying.

These instructions are from the OOP CMR V.I.P. kit

Two different wire bends are made.

The upper bent wire goes into a small hole in the body tube.

The bottom wire is bent into a rounded "W" and is held on by going around the fins.

Both wires are taped (or card stock strips are glued) around a launch lug. According to the CMR catalog, the launch lug is around 5" long.

The pop lug is fitted on the rocket at the launcher. A wrap or two of tape goes onto the top of the launch rod. At ignition, the rocket slides up to the top of the launch rod. The top of the pop lug hits the tape wrap and is left on the rod. The rocket continues on its flight without a launch lug.

I'll be using one of the altimeter vent holes for the top bent wire insertion. The upper bend will be a doubled over wire as opposed to the single end.

The first bend is easy enough, near the center of the wire.

TIPS: The tape strip is to direct the next bends. I found it very hard to get the "mirrored" bends accurate. Setting small tape strips at the bend points lets you set the pliers at the same place on both sides.

On the left is the two outward bends. That first tape strip is removed.

Two more small strips of tape set up the next bends.

The bottom is bent round and the width of the half circle sets the wire end tight to the side of the down wire on the right.

In the comments below, let me know if they are still used in contest flying.

These instructions are from the OOP CMR V.I.P. kit

Two different wire bends are made.

The upper bent wire goes into a small hole in the body tube.

The bottom wire is bent into a rounded "W" and is held on by going around the fins.

Both wires are taped (or card stock strips are glued) around a launch lug. According to the CMR catalog, the launch lug is around 5" long.

The pop lug is fitted on the rocket at the launcher. A wrap or two of tape goes onto the top of the launch rod. At ignition, the rocket slides up to the top of the launch rod. The top of the pop lug hits the tape wrap and is left on the rod. The rocket continues on its flight without a launch lug.

I'll be using one of the altimeter vent holes for the top bent wire insertion. The upper bend will be a doubled over wire as opposed to the single end.

The first bend is easy enough, near the center of the wire.

TIPS: The tape strip is to direct the next bends. I found it very hard to get the "mirrored" bends accurate. Setting small tape strips at the bend points lets you set the pliers at the same place on both sides.

On the left is the two outward bends. That first tape strip is removed.

Two more small strips of tape set up the next bends.

The bottom is bent round and the width of the half circle sets the wire end tight to the side of the down wire on the right.

More in the next post . . .

Subscribe to:

Posts (Atom)