The instructions say to start applying the bottom decals first. The Bottom View was a bit confusing, the image was flipped. You'll definitely want the USAF and stars and bars decals on the opposite side.

I'd recommend going to the older Interceptor instructions on JimZs: CLICK HERE The decal pictures there might answer some placement questions.

Previous builds on RocketReviews.com talked about the decals being thin. They were right!

The lower left vertical line broke and had to be reassembled. I've learned through past experience - don't start with the largest decals!

TIP: Start with smaller decals set in an area that won't be seen. If you have problems with them, these flaked or folded first decals might not be noticed.

This bottom front decal flaked at the upper left vent corner.

I couldn't fix it so the bottom vent was cut off to match the upper broken vent.

Before proceeding, both decal sheets got a spray of Krylon UV acrylic clear.

The underside of the wing has large decals that go over the root edge fillet and up the body tube.

After the decal was centered on the wing the line in the decal didn't meet at the root edge.

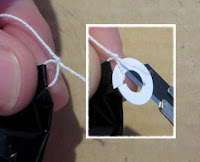

Roll a wet Q-tip to press the decal into the fillet area.