Finally get to add some color!

It's been difficult with the afternoon rain. I like to wait two days before masking and spraying over the first color. Just when I'm ready to spray around 2:30 p.m. (when the humidity is low) the rain starts.

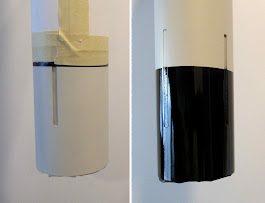

The low end of the lower body tube gets a around the tube mask and black paint sprayed. I know it's gloss, but I'll follow up with a clear dull coat.

The high end of the upper tube gets a darker gray.

The picture on the left shows the mask, the right side picture is after the tape was lifted.

There are actually four different colors on the main body. From the bottom up is black, then insignia white - a very light gray.

The upper tube is insignia white and a darker gray is at the top.

The nose cone is sprayed a light gray which is darker than the insignia white.

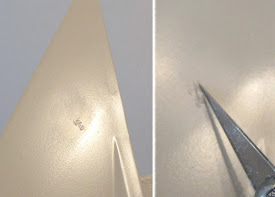

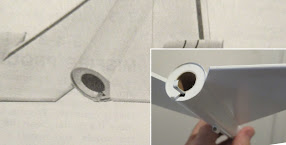

I placed the sticker strip over the leading edge as evenly and tight as I could.

Two days later, a lift shows.

FIX: I carefully cut through the center of the lift area. One side was pressed down, the other side "flap" was folded over. The right side picture shows the fix.

Maddening.