December launches aren't as busy as last months two-day Bunnell Blast. Still, a good group showed up. Temperature and the winds were moderate.

My Odd'l Rockets

PIGASUS flew first with a Quest B6-4.

There was a slight weather cock into the wind and it landed just just to one side of the (toxic) runoff trough. Estimated altitude was near 300'.

I was pleased to meet Leo Nutz today.

If you haven't already, stop by his website. It's a great compilation of kit data.

CLICK HERE So you think you're a collector?

Leo knows about and still flys Vashon rockets. The first rocket I ever owned was a Vashon Valkrie 2. We compared some memories about the Estes "Cold Power" series of Freon propelled rockets.

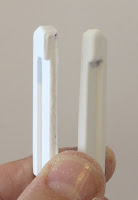

I did a test flight of the soon to be released Mercury Engineering (BMS) 3" diameter

SCHOOL ROCKET.

With a D12-3 it had a straight boost to 300'.

At ejection the Kevlar shock cord actually broke through the plywood centering ring! I've never had that happen before.

The nose cone touched town easily under the 18" parachute, while the body tube nosed in.

Even though the body tube was 1" into the soft soil there wasn't any damage or crimping of the strong 3" tube.

Mark Laiuppa brought his two stage Estes Omega.

He adapted a small digital spy camera to replace the Super 8 film Cineroc.

A beautiful flight with a D12-0 to a D12-5.

The Quest

STILETTO was my best flight of the day with a Estes D12-5.

Altitude was an estimated 750'.

At ejection the chute got hung up on the body, the rocket slowly spun and fell horizontal with no damage.

After last month's engine mount ejection I had to give the Quest

MAGNUM another flight.

With two C6-5 engines ignited by Quest Q2G2s, the Estes Altimeter read 483'. That's still not as high as I would have expected. The instructions predict 900 feet with two C6-5s.

At ejection one chute shroud line broke. No damage at recovery.

The wasted engine of the day -

I thought I'd loaded a Quest B6-4 in my

CHEROKEE GOON.

Altitude was low and it turned out the engine was an A6-4. To make up for my mistake, it was reloaded and flown again with a Quest B6-4.

Apogee was around 450'. No damage under the 12" red Estes parachute.

Six up, six down with two needing minor repairs.