This is one of my favorite designs and paint scheme.

Brian Coyle brought his to the Orlando ROCK launch a few years back and I've wanted to build one ever since.

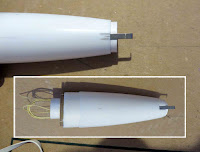

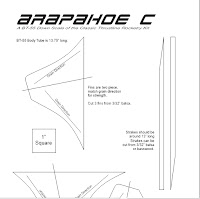

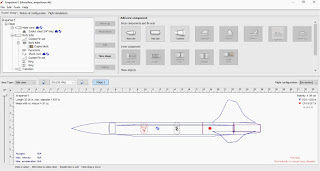

The original Thrustline kit was BT-60 based and D powered. Mine was a downscale BT-55 version for 18mm engines. I kept the Indian theme with the "Kokopelli" name.

This one used metallic red paint. With this paint pattern any second trim color works. I've seen it in yellow, orange, blue, green or gold.

UPDATE: I've flown the Kokopelli three times with the standard A8-3, B6-4 and C6-5 engines.

The A8-3 was a successful launch but altitude was too low. This BT-55 sized model is best with the B6-4 and C6-5 engines.