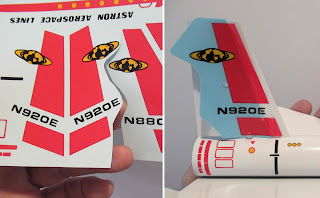

Before soaking the long narrow side decals - Cut a relief at the bottom of the decal to clear the small front canard fins on both sides.

If you have built the Low Boom SST, you know about the long decals that can stretch.

TIP: I cut the long side stripe decal in two halves. Trust me on this one!

Apply the front half, let dry, then transfer the rear half.

The rear surface of the engine mount centering ring is even with the end of the BT-55 booster body tube. This is why you'll want to sand centering rings flat (before assembling the engine mount) so on the finished model the ring end will show a smooth surface.

I hadn't glued the engine mount in the body yet and it still needed to be painted gloss white. The rings and the extension of the engine hook were taped off and sprayed.

The interior of the glider nozzle is black. I used a wide point black Sharpie to color the inside surface.

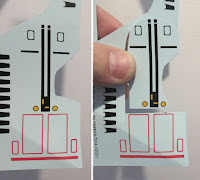

On the left you can see some of the black on the edge of the nozzle.

Some

very light sanding with 800 grit removed the black ink and gave a clean, white edge.

Before gluing the nozzle in the rear of the glider,

You can still do a little forming of the circle shape if it ended up slightly oval.

The nozzle is glued into the rear of the glider, with the centering ring even with the end of the tube.

TIP: Rotate and line up the shroud seam at the bottom and it won't be as noticeable.