They feel denser and stronger.

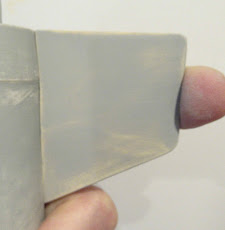

The picture shows the BT-60 tube lower tube. The seams are very tight and were easily filled with CWF,

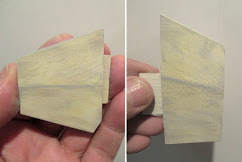

The upper tubes didn't need any CWF, I couldn't find the seam recess! Just a good shot of filler/primer and sanding should take care of anything remaining,

Here the shorter tubes are slid onto rolled cardstock handles for a filler/primer spray.

Above - the BT-60 shot with gray filler/primer.

After sanding with 400 grit.