Some CWF was dropped in using a toothpick and allowed to dry. It took another drop of CWF to fill as the first application shrunk as it dried.

TIP: There are visible inside areas that would be impossible to shoot with a spray can once assembled. I could use a brushed enamel paint, but I didn't want to seal the glue areas.

I ended up using an alcohol based "brush" marker. It's a flexible soft marker that allows you to get into tight areas. I couldn't blacken the tightest inside corners, but these areas won't be seen.

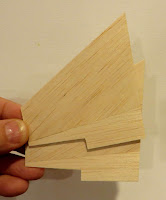

More areas that would be hard to reach with a spray can -

More areas that would be hard to reach with a spray can -

There are tight inside corners at the root edges of the vanes. You might use too much paint tying to cover the surrounding white surfaces.

I went ahead and sprayed some black concentrating on the inside corners. This showed me more glue boogers that required sanding. The pictures show after that sanding.