Earlier posts had the interior support tubes sanded down so the edges could touch.

More liquid plastic cement with finger pressure on both sides while the glue set up.

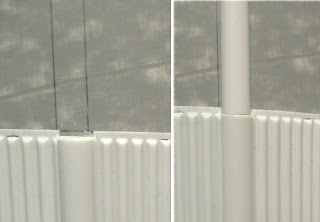

Here's how they actually look. The root edges are facing each other.

On the right the front hull piece fits well over the BT-50 main tube. Do plenty of dry fits before gluing the wing in place.

GOTCHA: Those tips above the round center area do not have to touch! If they touch you might not get the angled "down" dihedral. Most of the gap between the tips will be covered by the Access Boom Detail vacu-form piece.

Check the decal drawings in the instructions. The outside edge of the wing should be below the centerline joint (pencil line) at the body tube.