(I can't take all this excitement!)

5. Estes CITATION PATRIOT

You gotta love a big, dumb rocket! Okay, not really dumb.

This reissue kit was very well produced with big, tricky water slide decals!

To see the build: CLICK HERE

5. Quest STRIKER AGM

Not the greatest kit but was fun to paint and decal it like the Enertek Astro 2000. Fin fit always seems poor against the plastic boat tail.

To see the build: CLICK HERE

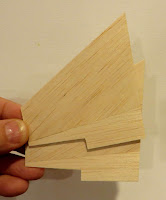

4. Apogee MINI CONDOR B/G

I've never had much luck with boost gliders until NARAM 60. After some test tosses my first flight had a tight turn for 25 seconds. There was too much weight on one wing tip. I guessed and pinched off a bit of clay.

The next flight duration was over 3 minutes long! The timers could only see it for a minute and a half, it didn't circle. A LONG recovery walk!

For the build: CLICK HERE

3. Estes DRAGON SHIP 7 Clone

3. Estes DRAGON SHIP 7 CloneA very involved build for the NARAM 60 Classics competition. I got high build points, but my documentation was sorely lacking. The judges wanted it to look just like the Estes catalog page. Over the gray paint, my orange decals ended up looking maroon.

For the build: CLICK HERE

2. Vashon VALKYRIE II

I'd been looking (and Ebay bidding) on original Vashon V2s for a few years. This was the first model rocket I ever owned in wais missing but I cobbled together a look-alike. The parachute tube is a BT-50H with a wrap of chrome Trim Monokote. The nose cone was fashioned from a balsa cone in the spare parts drawer.

For the build: CLICK HERE

And the NUMBER ONE build and probably best kit of the year -

1. BMS SATURN V

A very well engineered kit. Just the right amount of detailing in a manageable size.

On the blog in 2018 -

23 Models were built. The Semroc Saturn 1B and Orbital Transport aren't included, they are still under construction.

According to my Flight Log on rocketreviews.com, I had 82 Launches in 2018, 29 more than in 2017.

To see previous year Top 10 listings, do a search for "Top 10" in the search bar on the upper right.