Just got this from Roger at JonRocket.com

We just received the new Estes price list for July (good thing they

didn't wait until the last minute!)

The list price of the PSII "Launch Base" has dropped from 79.99 to 49.99.

The list prices for the Leviathan, Ventris, Partizon, and Argent have

dropped to 44.99.

The list price for C11 motors is dropping to 7.99, but there will be

just two in a pack.

The list price for D12 motors is dropping to 11.99, but there will be

just two in a pack.

-- Roger

The price drop for the PS11 Launcher is a good thing. I always thought it was high considering it's made of PVC pipe.

The PS11 model prices are better. Most have bought their share during the recent sales.

Doing some quick math -

Old 3 pack retail prices:

Three C11 Engines were $11.79 retail or - $3.93 each

Three D12 Engines were $17.79 retail or - $5.83 each

New 2 pack retail prices:

Two C11 Engines are now $7.99 or - $3.99 each ($.06 more per engine)

Two D12 Engines are now $11.99 or - $5.99 each ($.16 more per engine)

Monday, June 30, 2014

Fliskits MACME Shrew Build, Part 3, Centering Rings

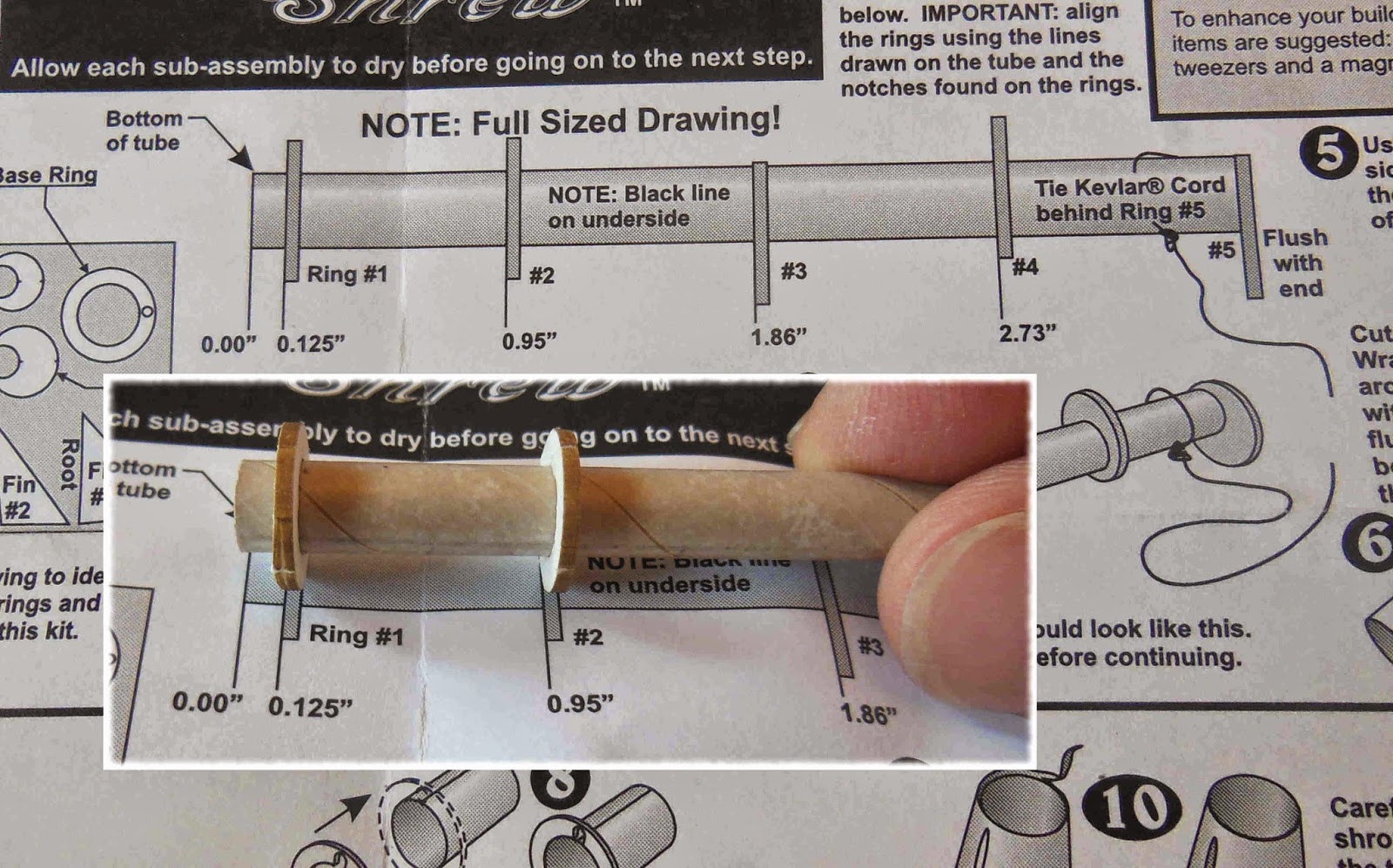

You are advised to mark the rings - A good idea.

I didn't pack a ruler broken down into hundredths.

The instruction drawing is full size and a better reference over pencil markings anyway.

Set the tube and rings over the drawing for gluing.

The rings were a little loose on the BT-2.5 tube.

I trimmed a coffee stirring stick to a point and used that to apply small dots of glue to the ring tube joint.

The excess glue was smoothed out with a Q-tip.

I only used three small dots of glue and let that dry. The small glue dots will allow for any re-positioning before the real, full fillets are applied.

The rear rings #1 and #2 were glued on first. They are the only "centered" rings. I did this to practice first on the easiest rings before taking on the offset rings, 3, 4, an 5.

Ring 1 was starting to split.

The split was slightly widened with a knife blade to allow glue to get in.

Glue was pressed in with the knife and tweezers squeezed the gap shut.

Here's the five rings in place.

The inset picture shows the top view.

I looked down the tic cuts at the top of the rings to line them up.

The fit and alignment are critical for the tube segments added later.

Take extra time to be sure everything is straight and placed correctly.

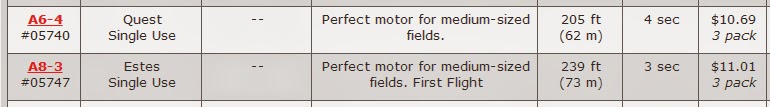

More Interesting A10 and A8 Engine Comparisons

Scroll down to the bottom of the page.

These are RockSim altitude comparisons. Granted, some simulator predictions are on the high side. The results are still interesting.

With the 13mm A10-3t engine and the 13/18mm Estes adapter, the Apprentice reaches 270 feet.

With the 18mm A8-3 engine (no adapter) the same Apprentice peaks at 239 feet!

21 more feet altitude with the A10-3t engine!

The A10-3t 13mm engine four pack is the same price as a three pack of A8-3s.I'm buying more A10-3t engines now over the A8-3s for the cost savings alone.

TRIVIA: The Apogee Apprentice is the new labeled version of the Starlight Minute Man model.

Sunday, June 29, 2014

Fliskits MACME Shrew Build, Part 2, Engine Mount and Marking

The internal BT-2.5 (motor mount) tube is cut to 3 5/8" long.

A piece of paper was wrapped and taped for a marking guide.

This tubing is small and strong. It cut very easily.

The instructions say to install the engine block using a MicroMaxx engine casing. I didn't pack one with me.

I did have some coffee stirring sticks that were just under 1/4" wide.

These were marked at 1" (MMX engine length) and 7/8" so the engine would stick out 1/8" with the block glued in place.

A ring of glue was placed inside the tube with a Q-tip marked at 3/4".

The glue ring was set slightly lower than the final location for the engine block. This insures the block will slide into the glue ring and hopefully make a small fillet above the engine block.

The instructions have you draw a black line down one side of the engine mount tube and a red line directly opposite it.

I don't have colored pens so I'll just have to be careful not to get the sides mixed up.

(Later I got the colored pens and did it right!)

This tube is too small a diameter to fit into an aluminum angle or door frame.

I used my fingers as a depth gauge and did the best I could.

Thailand Saucer Rockets Part 2

Here's how they start the LPR smaller spinning saucers in Thailand.

CLICK HERE

Check out some "launches" at :55, 2:12, 2:40

and a closeup of the saucer at 3:40.

No NAR Safety Code in Thailand.

Here's a video of a MPR saucer.

CLICK HERE

Maybe a use for the long burn Quest D5 engines?

NO! Bad idea. Forget I even mentioned that.

It goes without saying - Not Recommended!!!

CLICK HERE

Check out some "launches" at :55, 2:12, 2:40

and a closeup of the saucer at 3:40.

No NAR Safety Code in Thailand.

Here's a video of a MPR saucer.

CLICK HERE

Maybe a use for the long burn Quest D5 engines?

NO! Bad idea. Forget I even mentioned that.

It goes without saying - Not Recommended!!!

Saturday, June 28, 2014

Fliskits MACME Shrew Build, Part 1, Parts

Here's the one kit I packed for Mexico.

It's small with strong tubes. I could put this into my carry-on bag for a more gentle transit on the plane.

With the available skins there is no filling or painting! Perfect for an "away build".

This is a MMX downscale of one of the more popular Flis kits.

When finished it'll stand 4.42" tall. The body sections are BT-5 based.

The parts going clockwise from left to right:

Pattern Sheet, Clay weight

Nose Block, Kevlar cord anchor nail

Streamer 1/2" X 12" long, Stiff Kevlar 24" long

Instructions, Laser cut ring and fin sheet

Launch Lug, Engine Block

BT-5 tube 5 3/16" long, BT-2.5 tube 5 1/8" long

Parts of interest:

Pattern sheet for cutting tube segments, base shroud and nose cone cap, all printed on 24 lb. stock

Kevlar is stiff, not braided

The smallest nose block I've ever seen

Thick card stock rings and fins, very clean laser cuts

If you go to the FlisKits website you can download the skins and print them at home CLICK HERE

I picked the standard print, a Mercury Deadstone decor is also there.

I made extras and all got a shot of clear coat.

I scanned the pattern sheet and printed up a few more to be safe.

This build may seem a little long for such a small model. Fitting all the tube angles takes some extra time.

Many of the build ideas can probably be used on the larger FlisKits A.C.M.E. Spitfire.

A Letter Worth Posting

A letter from Andy that sizes up what we've all been through building rockets:

I am a long-time follower of your blog and really enjoy it. I have been in and out of the rocketry hobby since the mid 1970's. I jump back and forth between rocketry and plastic model building.

I am a long-time follower of your blog and really enjoy it. I have been in and out of the rocketry hobby since the mid 1970's. I jump back and forth between rocketry and plastic model building.

Good luck on that next build,

Hi,

I am a long-time follower of your blog and really enjoy it. I have been in and out of the rocketry hobby since the mid 1970's. I jump back and forth between rocketry and plastic model building.

I am a long-time follower of your blog and really enjoy it. I have been in and out of the rocketry hobby since the mid 1970's. I jump back and forth between rocketry and plastic model building.

Anyway, here is my question:

Have you ever gone through periods where you seem to screw up every model you try to build? Even the simple ones! It is like my skills just disappear!

I look and the rockets on the shelf that built and they look pretty good (no ego intended), then I look at my latest skill level 1 or 2 that I just can't get a handle on!

Am I the only one to go through this?

All the best,

Andy

Memphis, TN

_________________________________________________________________________

_________________________________________________________________________

Hi Andy,

Thanks for writing.

Oh yeah - we all have streaks where things don't go well.

I can equate this with playing the violin. I sold mine!

After playing violin for years my ear got better, almost to the point where I couldn't play double stops (two note chords) without cringing.

Same thing with rockets.

The more builds you do, the better (and pickier) you get judging your own work.

The more builds you do, the better (and pickier) you get judging your own work.

And there are new challenges -

I had a bad batch of Gloss White Rustoleum 2X where every can I bought shot out cottage cheese. Luckily it sanded off pretty easily and the newer cans are better.

Estes changes their "balsa" to Tung wood, that changes things.

Body tubes are not the quality they once were. Some weaker tubes now have wide inside spirals.

I try for clean builds and paint. But, you have to draw the line somewhere.

The "perfect" finish won't be perfect after a few flights.

On the other hand, a well built and finished model will last through many more flights.

The repairs on a better build are easier to fix.

The repairs on a better build are easier to fix.

I like to think I'm making forward progress on each new finished and flown model.

Sometimes it feels like a step back. The next build could be a step forward.

Good luck on that next build,

Chris Michielssen

Odd'l Rockets

Anybody recognize the "Mailman Art" at the top right?

Friday, June 27, 2014

Quest Aurora Finished

The fin unit was slipped on and CA glued from the back. The instructions say to use a tape wrap but the fit of my fin can was tight without it.

This was an interesting build, the glider is a bit like the old Estes Orbital Transport.

With the black bands, the core booster tube looks like the Shuttle tubes in a Dr. Zooch kit.

With the black bands, the core booster tube looks like the Shuttle tubes in a Dr. Zooch kit.

The glider is a bit plain, just painted white. I was concerned more paint would add weight and hurt the recovery glide.

With the black bands, the core booster tube looks like the Shuttle tubes in a Dr. Zooch kit.

With the black bands, the core booster tube looks like the Shuttle tubes in a Dr. Zooch kit.

The glider is a bit plain, just painted white. I was concerned more paint would add weight and hurt the recovery glide.

Above you can see the extra lug glued next to the plastic fin post.

Above you can see the extra lug glued next to the plastic fin post.I should have cut down the end of the black post so it would be even with the lug length.

After some standoff adjustments the fit of the glider is very good.

It's definitely a better attachment than what was used on the Estes Orbital Transport. On windy day the O.T. glider flips around.

This cradle design solidly holds the glider.

The U.S. AIR FORCE stickers are already lifting on the edges.

Even More Kit Decal Problems

Cl(VII) on TRF -

Did a beautiful build of the Red River Rocketry Stratus.

A catalog quality build. Check out the pictures at post #23 CLICK HERE

"Now the first thing I was disappointed in with the kit, and admittedly this is entirely a matter of personal preference and could have been mitigated. The decals are really thin and fragile, at least compared to Estes or Quest Decals. I did not realize this in advance, so I went with them as is. If I were to do it again they would have gotten a few coats of something to toughen/thicken them up before applying. As I didn't do this and my skills are not refined with such delicate decals I have many small blemishes in the decals. That being said I am overall happy with how it came out, and there were a lot of those little buggers. I need to pick up some MicroSol and MicroSet on the way home. I hope that softening them will help with some of the wrinkles, and just let them lay down better."

My response:

Beautiful work, catalog quality build! Not a wood grain or tube seam to be found.

I wish the vendors would give you an extra "test" decal.

(I think I'll add an test decal to my Odd'l kits.)

That way you could try the test one first to see if you need an additional clear coat of Micro Scale Decal Film.

I usually try and test with the smallest decal, usually the company logo.

(Why put those on the model, everybody at the club launch knows who made the kit anyway.)

That gives me an idea of the soak time and how it well transfers from the backing onto the model surface.

If the image runs or the decal tears, I don't cut or soak any more decals -

I'll add a coat of the Micro Scale Decal Film. That thickens up the clear film and protects the image.

This 1 oz. bottle is expensive! I wish I knew what they were pouring into these little bottles. (I'll have to do a test one day, maybe it's just Future clear acrylic?)

Did a beautiful build of the Red River Rocketry Stratus.

A catalog quality build. Check out the pictures at post #23 CLICK HERE

"Now the first thing I was disappointed in with the kit, and admittedly this is entirely a matter of personal preference and could have been mitigated. The decals are really thin and fragile, at least compared to Estes or Quest Decals. I did not realize this in advance, so I went with them as is. If I were to do it again they would have gotten a few coats of something to toughen/thicken them up before applying. As I didn't do this and my skills are not refined with such delicate decals I have many small blemishes in the decals. That being said I am overall happy with how it came out, and there were a lot of those little buggers. I need to pick up some MicroSol and MicroSet on the way home. I hope that softening them will help with some of the wrinkles, and just let them lay down better."

My response:

Beautiful work, catalog quality build! Not a wood grain or tube seam to be found.

I wish the vendors would give you an extra "test" decal.

(I think I'll add an test decal to my Odd'l kits.)

That way you could try the test one first to see if you need an additional clear coat of Micro Scale Decal Film.

I usually try and test with the smallest decal, usually the company logo.

(Why put those on the model, everybody at the club launch knows who made the kit anyway.)

That gives me an idea of the soak time and how it well transfers from the backing onto the model surface.

If the image runs or the decal tears, I don't cut or soak any more decals -

I'll add a coat of the Micro Scale Decal Film. That thickens up the clear film and protects the image.

This 1 oz. bottle is expensive! I wish I knew what they were pouring into these little bottles. (I'll have to do a test one day, maybe it's just Future clear acrylic?)

Thursday, June 26, 2014

Rocket Festival in Thailand

On TRF David M posted a link to a

BAMBOO ROCKET FESTIVAL in Thailand

https://www.youtube.com/watch?v=RRQaXDafs_Y

This is the most entertaining video I've seen in years.

Well worth a look.

Check out 4:00, 6:00.

Sure, there are some explosions, but when these saucers work - it's amazing!

They sound like a old steam train chugging.

So grab a flaming stick and dance in the mud! Something for everybody.

BAMBOO ROCKET FESTIVAL in Thailand

https://www.youtube.com/watch?v=RRQaXDafs_Y

This is the most entertaining video I've seen in years.

Well worth a look.

Check out 4:00, 6:00.

Sure, there are some explosions, but when these saucers work - it's amazing!

They sound like a old steam train chugging.

So grab a flaming stick and dance in the mud! Something for everybody.

SkyTech Response

I got a comment response from the SkyTec Argentina rocket group on June 21 . . .

"Many thanks for your attention!!!

Our BP model rocket motors are made in 18, 24 and 32mm diameters.

Regarding the "Shadow" model, it has two "transported gliders", designed to be recovered back by means of free gliding. This model will be on sale in August, 2014, along with other models.

Our "Alfa 02" model s of slightly similar to traditional Estes QCC, Unlike the Alpha has its fins inclined forward (negative effect), but also could be built with "normal" fins (angled backward).

As to introduce our models in the U.S. market, we are planning to do so by 2015, provided that we could manage to establish agreements with US based sellers or dealers."

Here's a link to the original SkyTec blog post: CLICK HERE

Here's a new direct link to the kits page CLICK HERE

Here's your Spanish lesson for the day -

Cohete means ROCKET

Hey SkyTec -

Send some products my way! I'll be happy to do a build blog on the new models.

"Many thanks for your attention!!!

Our BP model rocket motors are made in 18, 24 and 32mm diameters.

Regarding the "Shadow" model, it has two "transported gliders", designed to be recovered back by means of free gliding. This model will be on sale in August, 2014, along with other models.

Our "Alfa 02" model s of slightly similar to traditional Estes QCC, Unlike the Alpha has its fins inclined forward (negative effect), but also could be built with "normal" fins (angled backward).

As to introduce our models in the U.S. market, we are planning to do so by 2015, provided that we could manage to establish agreements with US based sellers or dealers."

Here's a link to the original SkyTec blog post: CLICK HERE

Here's a new direct link to the kits page CLICK HERE

You are even offered a payment plan to buy the kits.

If the Argentina Peso Currency Calculator and my input is correct, here's some examples of pricing before the shipping costs are figured in:

Cirrus Kit $98 pesos = $12.05 US

V2 kit $145 pesos = $17.83 US

Exocet $233 pesos = $28.65 US

Here's a pic of the D12-6 engines and link to the engines page:

D15-6 engines $180 pesos = $22.14 US

C8 engines are also listed.

The SkyTek controller is HERE

The SkyTek launcher is HERE

C8 engines are also listed.

The SkyTek controller is HERE

The SkyTek launcher is HERE

Here's your Spanish lesson for the day -

Cohete means ROCKET

Hey SkyTec -

Send some products my way! I'll be happy to do a build blog on the new models.

This blog now reaches 1,000 readers a day, worldwide.

Contact me at: oddlrockets@bellsouth.net

Quest Aurora Build, Part 11, Stickers and Cleaning Up

The instructions say the glider will perform better is left unpainted.

I thought I'd go for a compromise, painting it while still keeping it as light as possible.

The balsa was filled with CWF. No gray primer filler was used.

The glider got two light coats of gloss white.

The instructions say to paint it light gray and the bottom of the wing black. I avoided some of the primer and paint coats.

TIP: Canopies like this never conform to the curves of a nose cone.

The canopy was cut into three separate pieces.

The back was set down first on the flat shoulder. Putting this piece down first will make it easier to center the larger window pieces.

Other USAF and star and bar stickers were set down on the wings and rudders.

TIP: The mask line on the black fin wasn't good. The root mask angle was just too tight for any tape to fit well.

I used a fine point Sharpie to draw in a better black line.

Set the side of the pen barrel against the straight lug to help draw a new line in the crack.

Here's the new black separation line.

You can't really see it unless you look close.

This really only works with a black pen on black paint. Black is black and the pen line will match up with the paint. Other colors never match.

I thought I'd go for a compromise, painting it while still keeping it as light as possible.

The balsa was filled with CWF. No gray primer filler was used.

The glider got two light coats of gloss white.

The instructions say to paint it light gray and the bottom of the wing black. I avoided some of the primer and paint coats.

TIP: Canopies like this never conform to the curves of a nose cone.

The canopy was cut into three separate pieces.

The back was set down first on the flat shoulder. Putting this piece down first will make it easier to center the larger window pieces.

Other USAF and star and bar stickers were set down on the wings and rudders.

TIP: The mask line on the black fin wasn't good. The root mask angle was just too tight for any tape to fit well.

I used a fine point Sharpie to draw in a better black line.

Set the side of the pen barrel against the straight lug to help draw a new line in the crack.

Here's the new black separation line.

You can't really see it unless you look close.

This really only works with a black pen on black paint. Black is black and the pen line will match up with the paint. Other colors never match.

Wednesday, June 25, 2014

Quest Aurora Build, Part 10, Booster Decor Bands

The booster body was an easy mask.

Mask off 1" from the top of the body tube.

Paint the upper area tan.

There are eight black bands going around the body. They are evenly spaced 1" apart. Plan ahead before applying any bands.

A line was drawn down the body for the thicker vertical band.

Pencil tick marks were made at 1" intervals down the vertical line.

A piece of paper was wrapped around the body for a straight reference line when wrapping the bands around the tube. At the top edge I did some pencil shading to better show the paper edge guide.

After the eight horizontals are in place, the long vertical strip will cover up the horizontal band seams.

There are plenty of "where do these go?" pieces.

The face card gives some locations, others were just made up.

In the end, the raised bands look good!

Different Quest Controller and Launcher on YouTube

For curiosity I searched "Model Rocket Building" to see where the blog came up.

I found a YouTube video where a Quest Astra III Starter Kit is opened up.

To see the video, CLICK HERE

The starter set is opened but the regular black Quest controller isn't there.

At :55 seconds in I saw this:

That is clearly the SKY pad and controller.

(This picture is from the Apogee website)

The Sky launcher is a close (Chinese made) copy of the old Estes Port-A-Pad.

The "Quest" controller (above pic) has the same white cable and yellow safety key.

I thought the guy on the video may have bought a starter set on Ebay where the seller had conveniently substituted another brand of launcher in place of the normal quest products. But, in the video you see instructions for the controller and the Quest logo is at the top of the page.

Quest already relabels and sells the imported Sky engines with their logo.

Maybe Quest ran low on their own branded controllers and launchers and temporarily switched out the Sky components?

I found a YouTube video where a Quest Astra III Starter Kit is opened up.

To see the video, CLICK HERE

The starter set is opened but the regular black Quest controller isn't there.

At :55 seconds in I saw this:

That is clearly the SKY pad and controller.

(This picture is from the Apogee website)

The Sky launcher is a close (Chinese made) copy of the old Estes Port-A-Pad.

The "Quest" controller (above pic) has the same white cable and yellow safety key.

I thought the guy on the video may have bought a starter set on Ebay where the seller had conveniently substituted another brand of launcher in place of the normal quest products. But, in the video you see instructions for the controller and the Quest logo is at the top of the page.

Quest already relabels and sells the imported Sky engines with their logo.

Maybe Quest ran low on their own branded controllers and launchers and temporarily switched out the Sky components?

Tuesday, June 24, 2014

Quest Aurora Build, Part 9, Cradle Fit and Parachute

In Step 20 a standoff was cut for the dowel connection.

The directions were followed, the standoff was cut to 1/8" tall X 1/2" long.

The inset picture shows the standoff is too short, it won't fit slide into the lug cradle.

The short standoff was removed and a new one cut, this time almost 1/4" tall. This will allow me to sand to the correct height.

After some sanding the fit is better and the cradle holds the glider well.

I've never been a fan of the shroud line "Gripper" reinforcements. They are too thick and don't easily fit in a small diameter body tube.

Here's an older Quest parachute pulled from another model.with the Gripper tabs.

You can see how they crease when packed.

I won't be using the kit supplied parachute. It's "crispy".

New 3 and 4FNC E2X Estes Kits Coming Soon

For any new fliers,

4FNC mean 4 Fins and a Nose Cone

E2X in Estes "speak" means Easy 2 eXecute (or build)

The SHOW STOPPER is a BT-60 based model, just over 26" tall.

CLICK HERE

Why not post a picture of the model? We've all seen this design 4FNC before.

On the same page, under "Resources", the instructions have already been posted.

Enlarge the picture at the right and check out the tape reinforcement for the plastic launch lug strip piece.

I've never seen one used before in a kit.

4FNC mean 4 Fins and a Nose Cone

E2X in Estes "speak" means Easy 2 eXecute (or build)

The SHOW STOPPER is a BT-60 based model, just over 26" tall.

CLICK HERE

Why not post a picture of the model? We've all seen this design 4FNC before.

On the same page, under "Resources", the instructions have already been posted.

Enlarge the picture at the right and check out the tape reinforcement for the plastic launch lug strip piece.

I've never seen one used before in a kit.

The other coming soon kit is the MAMMOTH. CLICK HERE

Here's some specs:

Pro Series II E2X

Length 59.1", Diameter 2", Estimated weight 13.3 oz.

Plastic fins, Self stick decals, Screw on motor retainer, 24" nylon parachute

Recommended Engines: E16-6, E16-8, F15-6, F15-8

Projected maximum altitude - 1600 feet.

Well, it's always nice to see new kits. I just prefer something you build.

Monday, June 23, 2014

Port-A-Pads Through The Years

I was curious about the design changes over the years and did some hunting on Ninfingers CLICK HERE

Here's the first all plastic launcher from 1970,

The Estes PORTA-PAD.

We've all owned one of these.

The first one I had was yellow plastic but I've seen later runs in orange.

Notice the round cutouts in the girder styled legs.

Then in 1984 it got a lower center of gravity.

Now molded in black.

Newly re-designed? It looks like the legs were just flipped over!

In 1989 the PORTA-PAD II was listed.

The round cutouts are now square.

There are only four cut out areas where there was six before.

Probably a cost-saving move using less plastic.

Here's where it got weird. Let's back up a few years.

Centuri introduces it's POWER TOWER in the 1975 catalog.

It's just the original Porta-Pad molded in black.

The only real difference is a metallic sticker down one leg and the Centuri angled deflector. Why is it weird?

This was probably the first time we noticed the assimilation of Centuri into the Estes line. Both were owned by the parent company Damon. More similar product lines were to come.

And yes, Centuri previously bought and sold re-branded Estes engines for years.

Don't get me started on this one!

I never liked the Lighting Bolt legs. It looks like a toy for an eight-year-old.

This design was one of the reasons I made the Adeptor for camera tripod launches. I wanted to get off the ground and launch from something that looked more professional.

The new Estes Astron II Pad and Controller are a big improvement. And, they've gone back to molding it in the retro orange color.

Quest Aurora Build, Part 8, Glider Cradle and Rudder Gluing

The inside edges of the wing were sanded for a better match for the dihedral angle.

Like the instructions showed, the glider body was used to help set the angle. The tip was raised 1 3/8" from the table surface.

One of the 2" lugs was glued on where the fin was removed earlier.

Plastic cement wouldn't hold it on so I used some medium CA.

One cradle plate piece is glued on each side of the launch lug.

At the open top the spread space is 7/16"

The tube is glued down the center joint of the glider wings.

The inset shows a small rudder in position.

The bottom of the wing joint is sanded flat for gluing the root edge of the large rudder.

Subscribe to:

Posts (Atom)