You can build the model as scale or sport style.

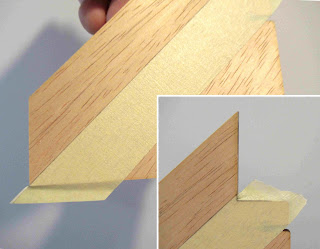

On the left is the Scale fin with the diamond taper leading edge.

The Sport fin has a rounded leading edge.

If you extend a parallel line from the lower left fin tip to the root edge, the shaded taper shown above is a little lower.

The inset picture shows where the taper line ends up at the root edge.

Normally I don't use masking tape to shape a taper like this, but the taper is wide and the balsa stock is thin for a fin this size.

To better see the thickness of the taper when sanding, I mark the leading edge with a marker.

To better see the thickness of the taper when sanding, I mark the leading edge with a marker.FIRST - give the leading edge a good wipe of medium CA glue. This seals the edge so the marker ink wont soak into the soft balsa.

The CA glue also strengthens the thin leading edge.

SECOND - Run a marker down the leading edge blackening it.

The edge taper is sanded with a sanding block with 220 grit sandpaper.

The edge taper is sanded with a sanding block with 220 grit sandpaper.Constantly check the blackened leading edge when sanding. The blackened edge is easier to see over a light beige balsa. The masking tape prevents you from sanding beyond the wide lower end of the taper.

Go light, you can sand through the tape.

Sand a bit, check the taper, flip over the fin and sand the other side evening up the edge taper.