. . . "These really are the sort of things I loved to build in the "Golden years" of Estes and Centuri, and I am trying to bring back some of that feeling in my kits. . . I also love the kits that had lots of decals and were of the Future/Fantasy variety, thus the Atlantis Refit and now the Interrogator."

This model does remind me of the Estes Interceptor era models, a classic look with plenty of detail..

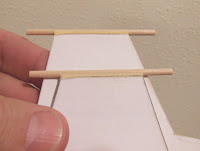

The overlapping main wing and intake tube are big features.

The PRM laminated fins strengthen the 1/16" thick fins.

The decals add a lot of fine detail.

This is my first Sirius kit. I'm impressed -

Highly recommended!