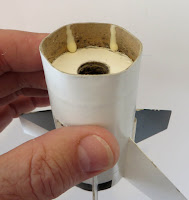

When exposed to the elements, you can see how the BT-5 tubes re-shaped the BT-60 lower fin can tube.

Wood glue was dripped down the sides where the tube cluster would make contact.

More glue was added to the bottoms of the BT-5 tubes before it was slid together.

Good thing I remembered there were two launch lugs!

A launch rod was slid between the upper and lower sections to insure all was lined up.

Here's the rebuilt model.

I didn't re-install an engine hook. The tube extends out the back enough for a tape wrap extension.

Replacement decals were printed but I haven't decided if they will be added. I probably won't add all the nose cone details.

Sometimes a rebuild requires re-finishing to look brand new.

Sometimes a rebuilt model has deserved its scars.