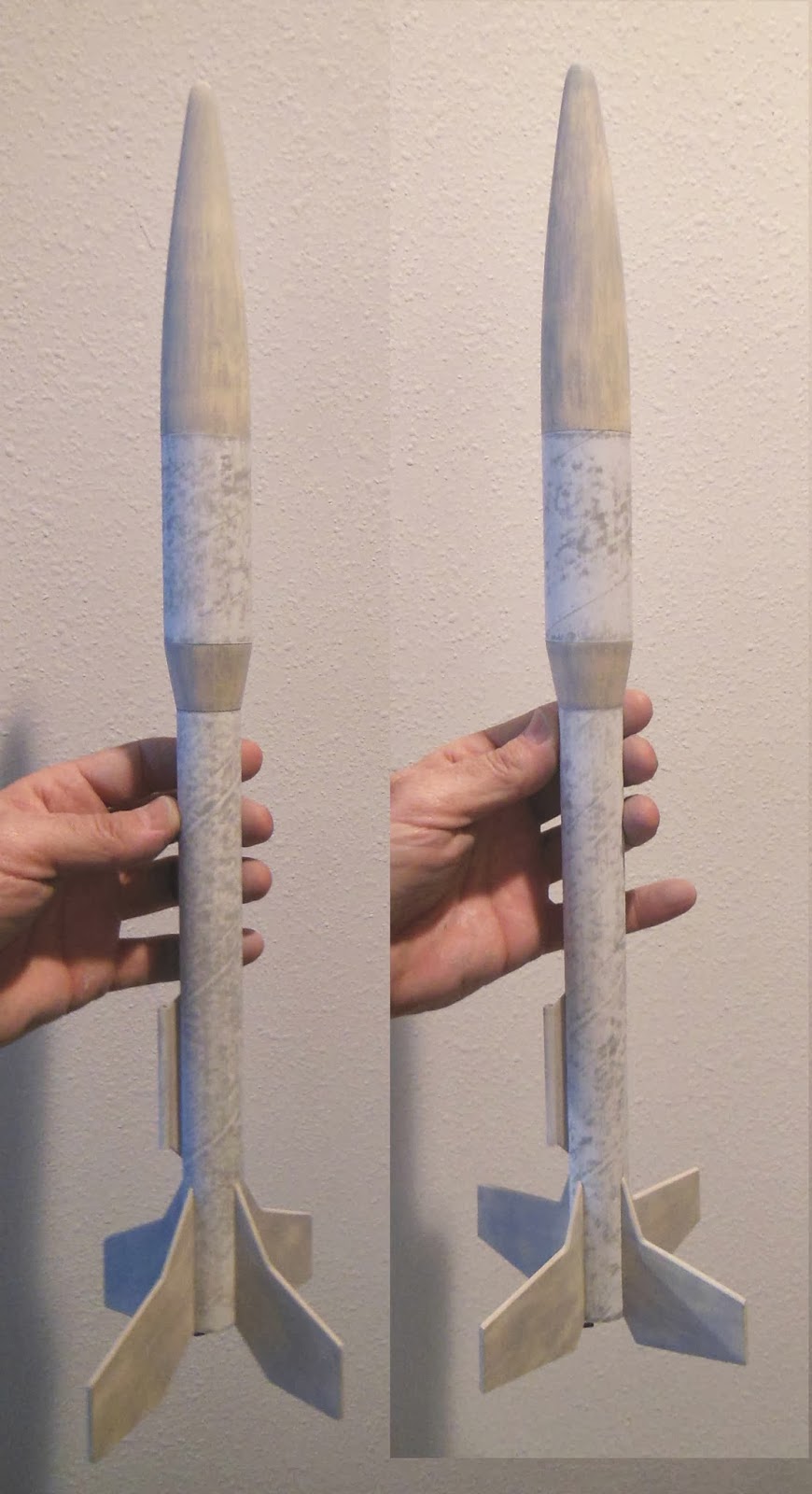

This is the payload section ready for paint.

To hold on to it for painting, copy paper got masking tape down one side. The tape strip was set on the paper edge half on, half off.

This was tightly wrapped around the shoulder making a thin round paper handle.

The instructions say to paint the entire payload section bright silver or platinum.

Looking at the face card I would assume the payload paint is the platinum.

I've seen some metallic paints used before but had been hesitant to try them.

This is Rustoleum #7250 Black Night Metallic. It was a few dollars more than my usual Rusto 2X paint.

The first light coat seemed to go on thin.

I checked it 10 minutes later and it felt fully dry!

When this build was done, Central Florida temps were below 60 degrees with low humidity.

The paint instructions said:

"For best appearance, apply one light coat followed by one wet coat."

Here is the dry payload section just 10 minutes after the wet coat.

You should see this one in the sunlight. It has just enough metallic bits in it to reflect the sunlight and still look black.

Compared to the face card it's very close.

I know, the last time I was excited about a new paint (the FixAll brand) I was disappointed. I still think the formulations got changed.

But so far - this Rusto Metallic is great!

I can see myself using this metallic paint for a lot of sport model finishes.