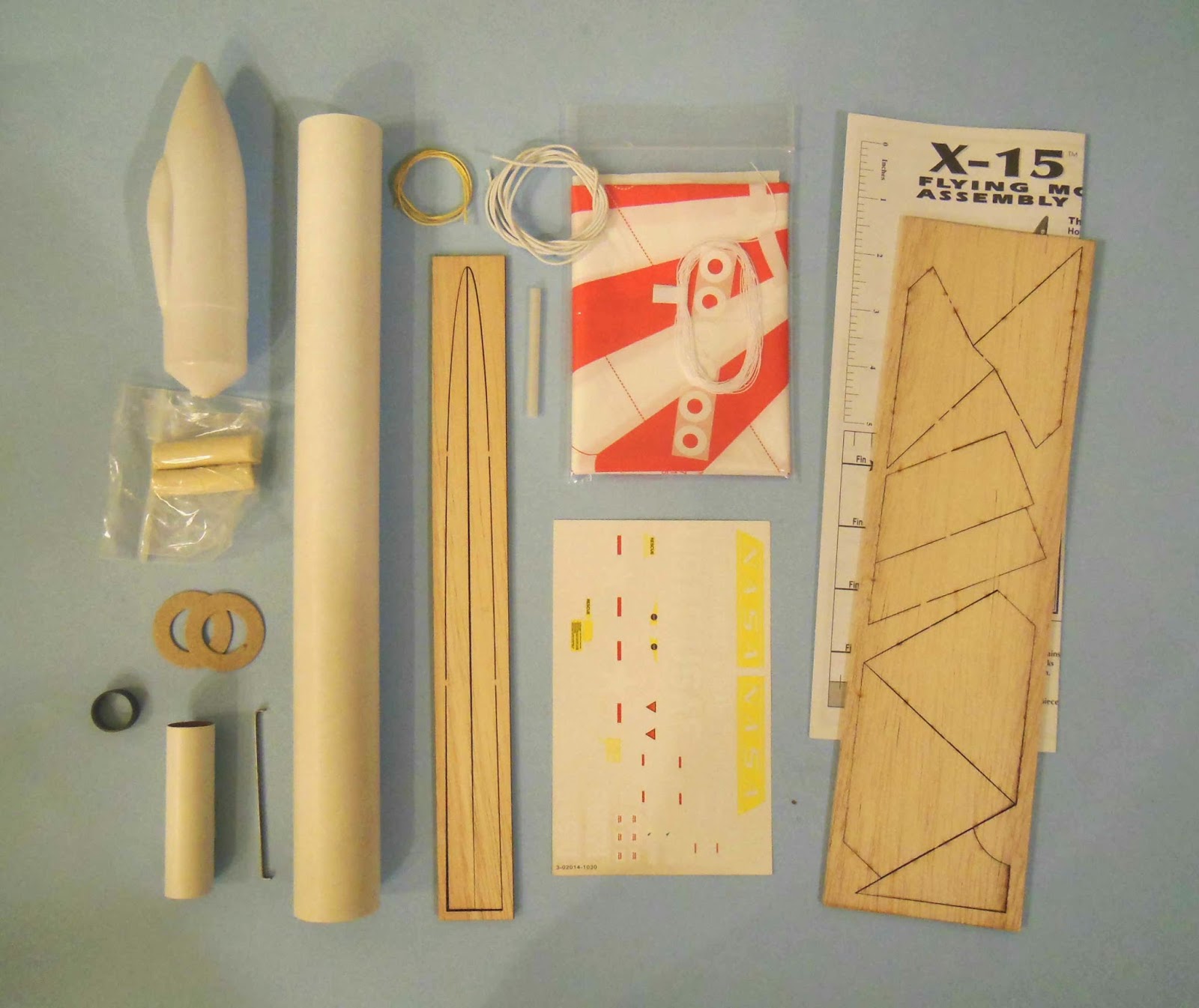

Quest did a good job capturing the feel of the X-15.

Even with the longer body tube its a good looking sport scale model.

Adding .25 oz. of nose weight it should be stable even with a C6-5 engine.

I've had this one on my build list for a while.

For now Quest has X-15 parts packs available, the decals were the hardest to find.

The gloss black paint sure shows fingerprints!

The Quest face card states the finished model weighs 1.69 oz.

My finished model weighs 2.45 oz. I did add .25 oz. of clay to the nose, the body tube is 2" longer and there is a card stock wrap inside the end of the body tube for a better fit of the nose cone. I tend to lay on the filler and paint heavier than most.

Unless it's a RTF, most finished models always seem to weigh more than the face card or catalog pages say.

EDIT: The Quest X-15 (stretched and with clay weight as shown) has flown twice now with a Estes B6-4 and C6-5. Both great, stable flights.