In the latest issue of the Apogee Peak Of Flight Newsletter, John Boren of Estes explains how he preps rockets before spraying color coats.

To read the article,

CLICK HERE

John Boren is a great designer, the models he has produced for Estes are outstanding.

I’m always curious how others prep and finish their models. Everybody has a method that works well for them.

Here’s a breakdown of the steps from the article -

1. With the balsa still on the sheet, spray two heavy coats of primer and sanding.

2. Bondo Spot Putty and sanding.

3. (Optional - If needed, repeat primer and sanding then Bondo and sanding.)

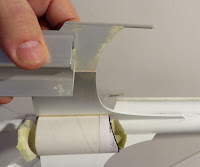

4. Glue together the model.

5. Spray with primer then apply Bondo where needed again.

6. Sand smooth.

7. Apply one more coat of primer and smooth with a light sanding sponge.

White undercoats follow.

In this method I counted six primer and Bondo treatments and sanding between coats -

before the first white undercoat! (The six coats and sanding are not including the optional third step shown in parenthesis.)

When I started in 1969, Estes recommended 4 coats of sanding sealer, sanding between coats. Centuri recommended using balsa fillercoat.

I always hated balsa filling. Four brushed coats of sealer and sanding and took a lot of time. Once I figured out how to do it correctly it did work well.

I am not knocking Mr. Boren’s methods. His posted builds show beautiful work.

Mr. Boren fills the balsa while it is still on the sheet. You'd still have to fill the edges later after the pieces are removed and the laser burnt edges cleaned up.

By comparison my prep schedule is pretty simple.

1. Remove the balsa from the sheet and sand off the burnt laser cut edges.

2. One application of thinned Carpenter’s Wood Filler and sanding.

3. One fairly heavy coat of Duplicolor Primer / Filler and sand - DONE!

Assemble the model and follow with white undercoats.

My filling method is not the only way to get it done.

Do what works for you, I simply prefer something that takes less time.